Due to its positive qualities, alabaster is widely used in the construction industry. However, when using it, it is important to be careful, because after contact of a dry powder with water, it hardens very quickly. It is this property of alabaster that made it so popular. Therefore, it is used in cases where it is necessary to carry out work quickly and without loss of quality, for example, when laying wires. In this article, we invite you to familiarize yourself with how to breed alabaster.

This material has the following properties:

- durability;

- when applying the mixture, a flat surface is formed;

- strength;

- waterproofness;

- resistance to cracking;

- high degree of sound insulation.

Among the positive aspects of alabaster are the following:

- Quick setting. In some jobs, this is very important.

- Fire resistance.

- When solidified, it does not shrink.

- Not dangerous to the human body.

- Ability to withstand loads.

Given the fact that alabaster absorbs moisture, it is not recommended to use it in rooms with high humidity.

Among the disadvantages can be identified poor resistance to dry and humid air. In the absence of moisture, alabaster loses its technical properties and simply crumbles.

As for the proportions, they are prescribed by building codes and regulations. For example, according to SNIP they are expressed as follows: 650 ml of water or lime mortar should be consumed per 1 kg of dry mixture. For fixing the wire during electrical work, 1 kg requires 500 ml of water. If it is necessary to obtain a liquid mixture of alabaster, then the proportion is 1: 1.

Unlike other solutions, such as putties, alabaster dries very quickly. For this reason, it is necessary to take seriously the choice of utensils for kneading alabaster dough. Using a metal bowl or bucket is not recommended. In this case, it will be difficult for you to remove residues from their surface. Therefore, it is best to dilute the solution in a rubber or plastic container. The dried alabaster is removed by squeezing the dishes.

If you need to knead in a small portion and once, then place a plastic bag in any convenient container. Securely fix the film around the edges. When finished, the tape is removed.

Alternatively, you can knead in an old rubber ball. To do this, cut it and knead it in the inside. You can also cut the plastic bottle (1.5 or 2 L) lengthwise.

Building alabaster is prepared in different proportions, according to the ratio with water, based on the purpose of its use. So, if it is necessary to align walls or partitions, then the mixture is mixed 1: 1. To install the junction boxes, a viscous mass is required - 2: 1.

If in the process of work the alabaster began to freeze, then do not try to add water to it. Throw it away immediately.

The mixing process itself boils down to adding the dry mixture to water, but not vice versa. The process of adding powder should be gradual. Otherwise, there is a risk that the entire mass will be taken up in a lump that cannot be broken. Alternatively, you can use a drill with a mixer attachment for stirring. In this case, you will be able to make a batch without a single lump.

In consistency, alabaster should resemble thick sour cream. For all the components of the mixture to react, it is enough to wait half a minute. After that, you can cover up the cracks or perform other actions. All work must be done quickly and neatly at the same time.

After finishing work, it is important to thoroughly rinse the entire tool, it is recommended to wash it in warm water.

Use only cold water at room temperature when mixing. Hot water speeds up the setting process several times.

So, we examined with you the features of alabaster for walls, as well as the technique of kneading it. By observing all the recommendations given, we hope that you will be able to make the correct kneading of alabaster.

Video

How to make alabaster more plastic will be discussed in the video:

For more than one millennium, this unique building material has been used in the construction and repair of premises, for decoration, making sculptures, and vessels. Alabaster, which is more often called plaster of paris, is aesthetic and easy to process.

On the intricacies of breeding alabaster

The main feature of water mixtures with alabaster is their fast solidification. This circumstance should be taken into account before proceeding with its breeding. In addition, the setting speed leads to the formation of hardened mixture residues in the containers from under it. Therefore, sometimes it is not easy to remove them from metal buckets and tanks.

To save yourself from mistakes when breeding alabaster, you must:

- prepare the mixture in small portions to prevent it from hardening before five minutes

- for dilution, it is better to use containers made of rubber or silicone, which are easy to clean

- put a plastic bag inside the container, the upper edge of which is securely fixed before stirring

- strictly observe the ratio of alabaster and water to prepare a specific solution

- pour dry alabaster into water gradually, stirring constantly until a mass without lumps and bubbles is obtained

At what proportions do you get stucco

Plaster of paris can be prepared for various finishing operations. For each of them, the regulatory documentation provides for certain requirements for the preparation of asbestos mortar. So, if it is supposed to be used to fill the strobes when performing work related to the laying of electrical wiring, one kilogram of alabaster must be diluted in half a liter of water.

In the case of preparing a plaster based on alabaster and lime, a kilogram of dry powder is diluted in 650 grams of lime mortar or water. A liquid putty solution, with the help of which irregularities on the walls are leveled, a kilogram of dry stucco is poured into a liter of water.

The main thing when breeding alabaster is to pour the dry mixture into the water. If this is done in small portions while stirring, the formation of lumps is minimized.

However, a quality solution is also provided:

- using power tools in the form of a drill with stirring attachments

- moistening the alabaster while stirring by hand, after which it is intensively stirred with a spatula

- the inadmissibility of diluting the mixture, which has set, with a liquid due to loss of quality

The main property of alabaster is the ability to quickly harden, mixing with water. This creates a solid and stone-like surface. Due to these properties, it is widely used in various branches of construction, industrial production, and art. With its help, seams in surfaces, holes and irregularities are closed.

When conducting electrical wiring with alabaster, wires and cables are fixed in specially prepared grooves. They putty walls and other surfaces of premises, various building structures.

However, ordinary alabaster quickly sets and hardens, after which it is not recommended to re-mix it with water. The quality of such a mixture deteriorates sharply.

Experienced craftsmen have their own methods of extending the action of the finished solution. According to one of them, a small amount of wallpaper glue is added to a container with such a solution.

After that, it is tightly closed with a piece of plastic wrap. The masters claim that this allows increasing the setting time without losing the quality of the alabaster mixture.

Types of alabaster

Different types of alabaster, as a natural mineral for the manufacture of stucco are mined in many countries.

So calcite alabaster is formed by streams of calcareous water and sediments. It can have various, mostly greenish shades. It is destroyed when exposed to hydrochloric acid, in contrast to gypsum alabaster.

Gypsum alabaster is the main raw material for the manufacture of gypsum. As a result of its processing at high temperatures in special devices, a powder-like binder for construction is obtained. If it is subjected to a finer grinding, the resulting powder can be used for molding operations. Specially purified raw materials are used for the production of gypsum for medical purposes.

There are rare forms of alabaster. In Italy, China and the USA, in addition to white, alabaster of pink and black colors is also mined. There is reddish and brown alabaster.

The setting time is different:

- fast-hardening, which begins to solidify after a couple of minutes and finally sets in a quarter of an hour

- normally hardening with the onset of setting not earlier than after six minutes and final hardening after half an hour

- hardening slowly, which begins to set no earlier than twenty minutes

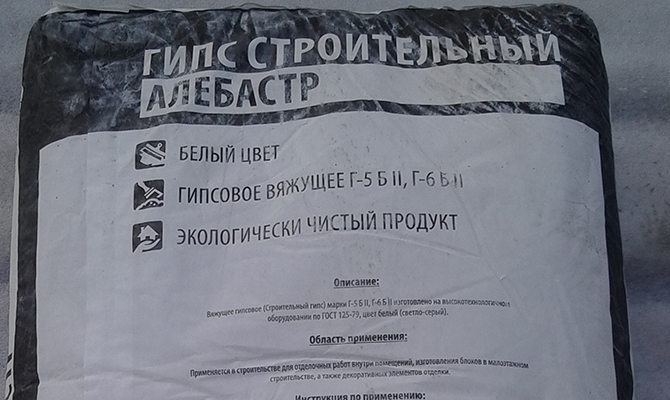

Most of the powder of modern stucco is white. The most applicable in construction is such gypsum, which is marked G-5, G-6.

Such alabaster is widely used for:

- plastering in dry rooms

- preparation of putty and plaster mixtures according to special recipes

- production of gypsum-based partition panels

- dry plaster in sheet form

- different types of drywall sheets

- gypsum fiber boards and plasterboard

Such stucco is used where high strength characteristics of the material are not required. Due to the presence of a coarse-grained component, it has lower strength and greater porosity.

To meet the needs of industries that need high-strength molds for casting parts for various purposes, to perform special work, it is necessary to opt for alabaster, which is distinguished by high strength, marked from G-13 to G-25. Such material complies with modern safety and construction standards.

The cost of quality alabaster

Common building alabaster is considered a relatively inexpensive building material, which makes it extremely popular in the market. It is sold mainly in durable paper multilayer bags, designed for 5-50 kg. One kilogram of ordinary G-5 building plaster can cost an average of 5-15 rubles.

Alabaster, characterized by its high strength, is significantly superior to conventional stucco. They are made from gypsum stone, both using traditional technologies and complex chemical-technological processes.

Therefore, such materials are indispensable for:

- sealing of drilled wells in the oil and gas industry

- production of ceramics and sculptures

- production of decorative elements for building objects

- in medicine for the manufacture of orthopedic and dental prostheses

- molding castings in jewelry making

- high-strength molds for the needs of some industries

Each builder has his own opinion on how to dilute alabaster. Most mixing techniques are based on personal experience and brand of material. However, there is a so-called standard kneading method that is used by many professionals in the construction industry.

Alabaster - areas of its use in construction

Alabaster is a dry fine-grained mixture that can be used for a large number of construction works. In most cases, the material is used for various construction tasks, and for creating a variety of decorative objects. Alabaster also performs other functions:

- serves for sealing seams, cracks, holes and chips;

- used for fixing cables in grooves when performing electrical work;

- used for the manufacture of lighthouses and slopes;

- used for filling enclosing structures.

In the case of the last two tasks, it is worth planting alabaster together with a cement solution. Its use in its pure form for putty and the manufacture of structures is impractical, since this material hardens very quickly.

Pros and cons of the mixture - the distinctive features of the material

Before working with the mixture, novice builders should study the properties of this material. It is not for nothing that the powder is in high demand among buyers, because it has good technological characteristics. First of all, they should include the almost instantaneous hardening of the building material when it comes into contact with water. Because of this, the mixture has practically no substitutes in cases where it is required to make a high-quality and fast finish of a given surface.

In addition to a high setting speed, the material also has a low density, which makes it possible to use it not only in construction, but also for repair work. The mixture has excellent refractory properties and is difficult to ignite. Another big plus of the material is good sound insulation. It is also worth noting that alabaster for construction work is a finishing material with a small mass, so it does not shrink during its hardening. In addition, it is absolutely safe for human health.

Despite the fact that alabaster diluted in water hardens rather quickly, it is not very durable. It is not able to withstand heavy loads, so it is not recommended to use it when decorating load-bearing walls. In addition, even a solid material tends to absorb large amounts of water vapor. Because of this, alabaster is not used in the decoration of rooms with high humidity. Hard alabaster breaks down very quickly when exposed to dry and hot air. In such conditions, the material disintegrates rather quickly.

Alabaster types - different mixes for specific tasks

Depending on the speed of hardening of alabaster, there are fast-hardening, medium-hardening and slow-hardening materials. The first type of mixture begins to harden within a few minutes after mixing and finally sets in 15 minutes after preparation. The material of the second type hardens in 7 minutes after cooking and becomes as hard as possible in 35 minutes. The latter type of alabaster begins to set after 20 minutes after mixing and finally hardens after 40 minutes.

In most cases, a white mixture with markings is used for construction purposes G-5 and G-6... It is used as a plaster in sheet form, in the production of various types of drywall, gypsum fiber, etc. Also, among the areas of application of the mixture, it is worth highlighting the production of panels for partitions and the preparation of putty mixtures according to specific recipes.

To meet the needs of various manufacturing industries where there is a need for high strength elements, it is worth using alabaster with markings G-13–G-25... Such mixtures fully comply with all construction and safety standards.

Preparing the container and diluting the mixture - all the subtleties for beginners

Having figured out what alabaster is and what types it is, consider the principles of mixing it in water. They differ slightly from the preparation of other building materials due to the high speed of hardening of alabaster.

Before diluting the mixture, you must select a vessel suitable for the work. Using a plastic bowl or bucket is not recommended, as the diluted material will dry out and you will need to scrape it off the sides of the container all the time. Because of this, most specialists prefer to work with alabaster in rubber vessels, mixing a small amount of powder each time. Thus, the remnants of the finished mixture can be completely removed by gently squeezing the container. A container for working with alabaster can be made by yourself using an unnecessary tire from a car or an old ball.

If the situation requires the dilution of a large amount of powder, then an ordinary plastic film can be put on the walls and bottom of the vessel and securely fixed inside the container. In the process, make sure that the container is not accidentally damaged, otherwise water will quickly flow out of it, and you will spoil the powder. In order to work with the material to give a good result, in the process of mixing the powder, it is worth strictly adhering to certain proportions. Many builders ignore this need, with the result that the mixture either hardens very quickly or does not dry out at all.

To prevent similar situations from happening to you, the first few times the mixture should be prepared according to a proven recipe. To begin with, you will need to pour half a liter of water into a rubber vessel. Next, take a bag of alabaster and add 1 kg of powder to the water. Do not pour out the portion you need right away. It is best to do this gradually, stirring the mixture with the other hand. The finished solution should be homogeneous, without lumps of adhered powder. During mixing, you need to pay attention to the walls of the container - there should be no powder residues on them.

Experienced experts advise not to overdo it with alabaster stirring. If you stir the substance for too long, the resulting material may lose its strength.

After about five minutes after mixing, the mixture will begin to thicken. Depending on the brand of powder, the mixture will fully harden in 20–35 minutes. Given this algorithm and the speed of hardening of the mixture, we can conclude that in one batch you need to prepare as much material as you can use for 5-7 minutes of work. A solution prepared according to this algorithm will be the best option for repairing cracks in the walls, fixing communications and other simple construction work.

Preparation of material for plastering

Mixing alabaster for wall plastering is slightly different from the first method of preparing the mixture. First you need to decide on the type of work to be done and, accordingly, the brand of the powder used. If the material is needed for the purpose of leveling the walls outside the building, then a mixture based on cement mortar is best for this. For the same work inside the house, a lime-based mixture will be optimal. As for alabaster specifically, a solution based on this powder and lime is ideal for eliminating various cracks and other errors.

Before direct kneading, it is best to prepare a dry mixture, which will later be filled with water with the addition of alabaster powder. As a vessel, you can use an old tire or other container with a flat bottom. The walls of the container should not be lower than 10 cm.

The mixing process begins with pouring sand into the vessel. After that, the lime "dough" is poured into the same container at the rate of 1 part of sand to 5 parts of lime. We take a spatula and mix the components thoroughly until a homogeneous mass appears. After that, you can gradually pour in the liquid, remembering to stir the mixture. As a result, the substance should resemble fatty sour cream.

Next, we proceed to preparing the "dough" from alabaster. It should be borne in mind that the amount of finished material must correspond to a lime mixture in a ratio of 1: 4. After that we shift the plaster "dough" into a vessel with lime and knead thoroughly, but not too long. Immediately after you have prepared the substance, you need to proceed to plastering work. If you plan to work alone, then you should familiarize yourself with the intricacies of the procedure before starting it.

The first stage is the so-called "sprinkling" of the coating. For this, the mixture is taken using a trowel - a construction shovel with a curved handle. To perform the first stage correctly, you need to scoop up a small amount of the mixture with a trowel and throw the solution onto the wall covering with a sharp movement of your hand. In this case, the main thing is not to overdo it, otherwise you will simply spray material on the wall.

During the second stage, you need to apply the primer with a wide spatula. If you make plaster on beacons, then the layer of the mixture must be leveled strictly along the mounted slats. Immediately after this, you will need to apply another thin layer of the material. It is very important to apply the last coat before the previous mixture dries. If you did not have time to do this, then the previous material should be sprayed with water.

When the top layer of the material is completely dry, it should be treated with a plastic construction float. This is done in a circular motion of the hand. In this case, you need to try as tightly as possible to press the tool against the treated surface and move counterclockwise. Preparing, kneading and applying the alabaster mixture is not difficult. The main thing to remember is the small amount of time that will be at your disposal.

Gypsum and alabaster powder - what are the differences?

Often, novice builders are faced with a situation when a consultant in a store asks to clarify what exactly is required for work - alabaster or gypsum powder. Many people think that both of these terms have the same meaning, although in reality this is not the case. There are several factors on which both of these materials differ from each other.

Firstly, alabaster is one of the varieties of gypsum building powder. The first can be used exclusively in construction, while the second has found application in medicine.

The second difference is that alabaster "dough" is harder than plaster mix. Therefore, the first material is often not used where the second is used.

The applied and dried gypsum mixture is much safer for humans. It does not give off vapors that alabaster can produce. In addition, gypsum coatings are less likely to develop fungus.

Alabaster is a dry mix, the main component of which is gypsum. Polymer additives provide its elasticity and adhesive properties. It is one of the most popular building materials used for renovation, construction, and decorative interior decoration.

Alabaster is sold as a white powder that is diluted with water. It differs from other similar materials in its fast solidification time, therefore it has 12 varieties. Alabaster grades are classified by compressive load and setting time, they are designated by the letter G and a number. For example, G25 means that the solidified layer can withstand compression of 25 kg / cm2.

How is alabaster used?

You should always dilute a small amount of the mixture with water, since its hardening time is short, it may not be calculated correctly. Alabaster is diluted with cold water to a viscous state, while first water is poured into the container, then powder is poured. Stir thoroughly and quickly, preferably mechanically, for example, with a special nozzle for a drill. The presence of lumps is unacceptable. After pouring the mixture into water, do not wait for it to get wet.

On the other hand, with manual stirring, wait until the water is completely absorbed into the alabaster. If the mixture is used to level the panels, then the brand with the longest curing time is purchased. For work on walls, ceilings, partitions, it is used to fill voids and containers.

On the other hand, with manual stirring, wait until the water is completely absorbed into the alabaster. If the mixture is used to level the panels, then the brand with the longest curing time is purchased. For work on walls, ceilings, partitions, it is used to fill voids and containers.

Its advantages lie in the ability to breathe, that is, the absorbed moisture returns back to the surrounding air. In addition, the use of alabaster is necessary to obtain a durable, hard, abrasion-resistant surface.

How to properly dilute the mixture?

Liquid alabaster construction application of which is required for leveling walls, partitions, is obtained by mixing 1 kg of the mixture and 1 liter of water. A viscous consistency is obtained if you take 1.5 kg for 1 liter of water. During the installation of electrical wiring, installation of the junction box, use a thick solution. It is made by mixing 2 kg of the mixture and 1 l of water. For such work, choose the brand with the fastest setting time.

If the solution in the container begins to solidify, it should be discarded, and a new one should be kneaded for work. It will not work again to dilute it with water, it hardens, it is impossible to "rejuvenate" it.

A little about the technique of work

Plastering walls with this material is produced to improve their sound and heat insulating properties. For this, a mixture with the longest hardening time is purchased, but the work still requires a certain skill. Such plaster gives the surface evenness and smoothness. For work, a wide spatula is used, on which the mixture is applied with a spatula of a smaller width. The work is carried out from the bottom up according to the same rules according to which the putty is applied, but much faster.

Alabaster - this is plaster of paris, which has a snow-white hue, sometimes gray and pale red. It has a significantly lower hardness than various minerals. Alabaster is a soft material, and only lags behind talc in properties. Alabaster is used in the production of small sculptural items, as well as watch boxes and other crafts. In our store " Mixes Moscow”(It is located where the building materials market is located near Auchan) there is a lot of this type of material.

How to dilute alabaster correctly?

First you need to choose the excellent alabaster in our store. For example, we sell dry building mixes Yunis Alabaster 5kg. There are purified alabaster mixtures, they are also sold with admixtures of mud. The main thing is that it should be noted on the packaging that this is a purified mixture. This composition mixes better and thoroughly closes holes. Thus, the material will last for a long time.

Before dissolving the alabaster, you need to take an old rubber ball and cut it into 2 parts. Alabaster lags well behind rubber and can be removed without problems. In addition, one ball can immediately provide you with containers in two quantities. If you stir this material in a regular bowl, then you will most likely spoil the solution and will no longer be able to use it. The material quickly hardens and after which it is not diluted with water, and the alabaster hardens, the dishes will be damaged.

If, nevertheless, you did not find a similar ball, then use a saucepan or bucket. However, before kneading alabaster, it is worth laying out the container from the inside with polyethylene. And this must be done so that there are no gaps. In addition, the edges of the plastic wrap must be hooked onto the bucket itself with rubber twine so that they cannot roll inward. It is clear that if alabaster gets into a bucket, then they can only be thrown away ...

Mixing the alabaster mortar is similar to the procedure for making wallpaper paste. First, the alabaster mixture is poured into a bowl of water. If it is one kilogram of material, then about 0.5 liters of water will be needed for the composition. Everything is thoroughly mixed in order to form a mass similar in consistency to thick sour cream.

After the mixture has been prepared, you need to wait thirty seconds for the components to adhere, and then immediately start working. Otherwise, the composition will harden, so you have to re-mix the mixture. After all the work is completed, you need to immediately wash all the tools from the alabaster.