A heat accumulator is a device capable of accumulating thermal energy from a heat source when it is produced in excess, and then using its reserve if necessary.

The heat source can be a heating boiler, stove, solar collector, etc.

In fact, any massive body that has a temperature greater than absolute zero has a store of thermal energy. The amount of accumulated heat depends on the degree of heating and body weight.

For example, any building made of brick, stone or concrete blocks (materials capable of accumulating heat) is a heat accumulator, the continuous operation of which few people pay attention to. But it is precisely thanks to the heat reserve accumulated by the walls of the house that it is cool in a hot day and warm at night when the outside temperature drops, the natural ventilation system works, and there are no sharp temperature fluctuations during a short-term shutdown of heating or during ventilation.

Another example of a heat accumulator is a Russian stove or any other stone or brick heating stove. When burning firewood, the stove array accumulates thermal energy, and then, cooling down, gives it to the surrounding space.

The greater the weight of the stove, the more heat it has and the longer it can maintain a comfortable temperature in the room. It is for this reason that the traditional Russian stove is made massive, weighing up to one and a half tons or more, and it is heated periodically: once a day.

Traditionally, stones or baked bricks were used to accumulate heat, but their use is justified only for stove heating, the use of which in simple modern houses is not always convenient. To heat a modern home, heating boilers are more often used than stoves.

Which boilers need a heat accumulator?

A heat accumulator is necessary only for boilers that operate periodically: coal or wood. Boilers operating uninterruptedly (gas or electric), equipped with continuous fuel supply systems, long-burning boilers do not need heat accumulation.

Solid fuel traditional boilers need periodic laying of firewood, the time of complete combustion of fuel in them is no more than 3 hours. At the end of the combustion process, the coolant in the heating system will not only cool down to the temperature of the air in the room, but also in places of boundary pipeline laying (along the floor, in the basement, in the attic) it can freeze, forming ice plugs in the heating system that block the circulation of water.

In these conditions, we are no longer talking about comfortable conditions in the house, but about the integrity and safety of the heating system. The main task of heat accumulation in systems with a solid fuel heating boiler is to create a reserve of thermal energy, the use of which during the idle period of the boiler will help to avoid a sharp drop in temperature in the room and avoid freezing of the coolant.

Heat accumulator device

A heat accumulator for a heating boiler should be convenient not only for the accumulation of heat, but also for its further use. The only substance suitable for solving the problem is the coolant. It can be water or antifreeze placed in an impressive container included in the heating system.

To preserve heat, the container is additionally insulated: sheathed with mineral wool, foil, heat-insulating panels, installed on an insulated base.

The volume of the heat accumulator is chosen according to the principle, the more the better, but usually we are talking about a capacity of 2-5 m3. Another important addition: the tank must be airtight, with two holes: for connecting the pipeline.

The heat accumulator is connected to the heating system in parallel with the boiler according to the principle of a heating device with connection to both the supply and the return. Shut-off valves must be installed at the supply, allowing you to change the direction of movement of the coolant, letting it either only to heating devices, or only to the heat accumulator, or at the same time both there and there. As a rule, this is a three-way valve.

How does a heat accumulator work in a heating system?

With intensive burning of firewood in a solid fuel boiler, maximum heat generation occurs, which allows heating not only the radiators in the house, but also the water supply in the battery. After the firewood burns out, the heat from the boiler stops flowing, but the circulation of the coolant in the system continues: cold water rolls down, and a hotter coolant from the battery enters the system.

Return water, returning to the heating boiler, also passes through the accumulator. If the return temperature is higher than the temperature of the water in the tank, then the liquid inside is additionally heated by the return. If the return is cold, then, on the contrary, it is heated before entering the boiler, which reduces the temperature difference between the hot boiler and cold return water.

The larger the battery, the longer the system can work without "recharging".

Practical use

A heat accumulator in a heating system with a solid fuel boiler can be safely called a real find for its owners. It is this simple device that allows you to leave the house for several hours even in severe frosts, without fear for the safety of the heating system, sleep peacefully at night, without jumping up to the boiler to lay a new portion of firewood and not be afraid of the destruction of the boiler when too cold coolant enters it.

A three-way valve is used to control the operation of the heating system with a heat accumulator.

With it, you can open the movement of the hot coolant only to the heating devices, which is usually done if you want to quickly warm up the room. If the house is already hot, and the boiler continues to work, you can turn off the water supply to the radiators and send it only to the heat accumulator.

For simultaneous heating of heating devices and a heat accumulator, an intermediate position of the tap is selected.

Heat accumulator and circulation pump

As a rule, solid fuel boilers are used in gravity heating systems. In this case, the heat accumulator works due to natural convection: a cold coolant enters it through the lower pipe, and a more heated liquid flows upwards to the heating devices.

In systems with a circulation pump, the heat accumulator also works, but here the speed of the coolant is set by the pump, which undoubtedly has a positive effect on the operation of the entire heating system.

On the advantages and disadvantages

The installation of a heat accumulator makes the operation of the heating system stable, excluding sudden temperature changes not only in the house, but also in the flow of coolant into the boiler.

The only drawback of a heat storage tank is its size: a small capacity does not allow heat to be stored and used, and it is not always possible to find enough space for a large volume tank. Yes, and to install the tank, you will have to strengthen the foundation or place it in the basement.

Heat accumulator for heating boilers

Why do you need a heat accumulator for heating boilers? How is it set up and how does it work? Practical application of the heat accumulator

Heat accumulator for boiler

When designing a heating system, the main goals are comfort and reliability. The house should be warm and comfortable, and for this, hot coolant must always flow into the radiators without delays and temperature fluctuations.

With a solid fuel boiler, this is difficult to implement, because it is not always possible to fill a new portion of firewood or coal in time, and the combustion process itself is uneven. A heat accumulator for heating boilers will help to correct the situation.

With a simple design and principle of operation, it is able to get rid of a number of inconveniences and shortcomings of the classical heating scheme.

Why do you need

The heat accumulator is a well-insulated large-capacity tank filled with a coolant, water. Due to the high heat capacity of water, when the entire volume is heated, a significant supply of thermal power is accumulated in the tank, which can be used for its intended purpose at a time when the boiler cannot cope or is completely inactive.

The heat accumulator actually increases the volume of the coolant in the heating circuit, the heat capacity and, accordingly, the inertia of the entire system. It will take more energy and time to heat the entire volume with a limited heating power, but it will also take a very long time to cool the battery. If necessary, hot water from the accumulator can be supplied to the heating circuit and maintain a comfortable temperature in the house.

To appreciate the benefits of a heat storage, it is easiest to consider a few situations to begin with:

- A solid fuel boiler only periodically heats the water. At the moment of ignition, the power is minimal, during active combustion, the power increases to a maximum, after the bookmark burns out, it decreases again and so the cycle repeats. As a result, the temperature of the water in the circuit constantly fluctuates in a fairly large range,

- To obtain hot water, it is necessary to install an additional heat exchanger or an external boiler with indirect heating, which significantly affects the operation of the heating circuit,

- It is extremely difficult to connect additional heat sources to a heating system built around a solid fuel boiler. A complex interchange will be required, preferably with automatic control,

- Solid fuel boiler, even long-term burning, constantly requires the attention of the user. It is worth skipping the time for laying a new portion of fuel, as the coolant in the heating circuit is already starting to cool down, like the whole house,

- Often the maximum power of the boiler is excessive, especially in spring and summer, when maximum output is not required.

The solution for all of the above situations is a heat accumulator, moreover, uncompromising and the most affordable in terms of implementation and cost. It acts as a decoupling point between the solid fuel boiler and the heating circuit(s) and an excellent base platform for enabling additional functions.

By design, the heat accumulator can be:

- "empty" - a simple insulated container with a direct connection,

- with coil or pipe register as heat exchanger,

- with built-in boiler tank.

With a full body kit, the heat accumulator is capable of:

- Accumulate and store a significant amount of thermal energy, primarily excess, with its subsequent return to the heating circuit. Even if you miss one or two refills of wood and the boiler stops, the temperature in the house will drop by only a couple of degrees. For electric boilers, it is possible to set a schedule according to which electricity will be consumed only at night at a reduced rate, while during the day the heat will come from the heat accumulator,

- If there is a lower heat exchanger, connect additional heat sources, a solar collector, a spare boiler running on gas or diesel fuel, a geothermal heat pump,

- With built-in heating elements, be used as a backup source of heat in case the solid fuel boiler is not working or is turned off for maintenance and repair,

- In the presence of an upper heat exchanger - for connecting a DHW circuit or an indirect heating boiler. Some models of heat accumulators are equipped with a ready-made boiler located inside the main tank instead of a heat exchanger,

- Implement additional protection in systems with forced circulation in the event of a power outage, preventing overheating of the water in the boiler. Considering the tank as a hydraulic decoupling unit, it can be connected in a mixed circuit with a boiler, above it and pipes of a larger diameter to maintain natural circulation. At the same time, distribution to the radiators will be carried out by the pump forcibly.

The power accumulated by a heat accumulator (TA) is calculated based on the volume of the container, or rather the mass of the liquid in it, the specific heat of the liquid used to fill it, and the temperature difference, the maximum to which the liquid can be heated, and the minimum target, at which it can still be carried out. heat intake from the heat accumulator to the heating circuit.

- Q \u003d m * C * (T2-T1),

- m - mass, kg,

- C - specific heat W / kg * K,

- (T2-T1) - temperature delta, final and initial.

If the water in the boiler and, accordingly, in the TA is heated to 90ºС, and the lower threshold is taken equal to 50ºС, then the delta is equal to 40ºС. If we take water as filling TA, then one ton of water, when cooled by 40ºС, releases approximately 46 kWh of heat.

Heat accumulator for boiler

In the article you can read what a heat accumulator for a boiler is and how to choose it. Heat accumulator connection diagram and manufacturers.

Heat accumulator, its device and principle of operation.

Good day everyone! If you have landed on this page of my blog, then you are interested in at least 2 questions:

- What is a heat accumulator?

- How is a heat accumulator arranged?

I will start answering these questions in order.

What is a heat accumulator?

In order to answer this question, a definition needs to be given. It sounds as follows, a heat accumulator is a container in which a large volume of hot coolant accumulates. Outside, the container is covered with thermal insulation made of mineral wool or foamed polyethylene.

Why do you need a heat accumulator?

You ask: “Why do we need this overgrown thermos?” Everything is very simple here, it allows you to optimally use the heat given off by the boiler. Paired with a heat accumulator, a powerful boiler (most often solid fuel) always works. The boiler quickly and non-stop transfers heat from the burned fuel to the heat accumulator, and it, in turn, slowly and in the right mode gives this heat to the heating system. The volume of the system is much smaller than the capacity of the battery. This allows you to "stretch" the heat from the fuel over time. It turns out, in fact, a long-burning boiler. When the battery capacity is heated, the boiler constantly operates at full capacity, and this avoids the appearance of tarry condensate in the chimney and boiler.

How is a heat accumulator arranged?

As mentioned above, TA is a container in which hot water (or other coolant) accumulates. To make it clear, look at the following figure:

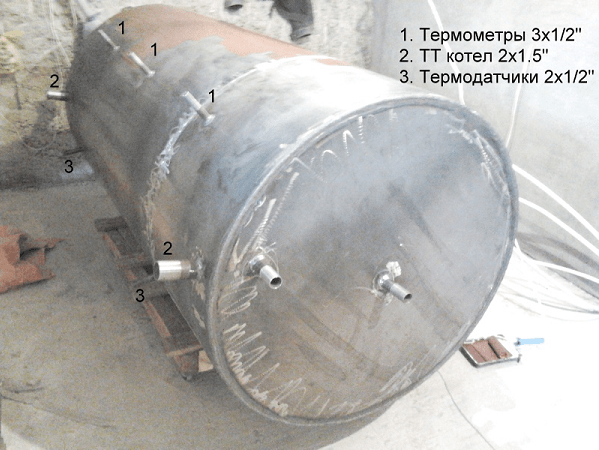

The tank has several nozzles for connecting various equipment:

- Thermal energy generator - boiler, solar collector, heat pump.

- Plate heat exchanger for heating hot water.

- Various boiler equipment - safety group, expansion tank and so on.

Water container materials.

Heat accumulator connection diagram.

Now let's look at how the battery is included in the heating system:

From this diagram it can be seen that the TA is included in the heating system as a hydraulic separator (hydraulic arrow). I recommend reading a separate article dedicated to this useful device. I will say briefly that such a switching scheme excludes the mutual influence of different circulation pumps and allows you to provide the boiler with the required volume of coolant, which has a positive effect on the life of the heat exchanger.

Heat accumulator and hot water supply.

Another important issue is the device in the house of hot water. Here TA can also come to the rescue. Of course, it is impossible to use water directly from the heating system for sanitary needs. But there are at least two solutions here:

- Connection to the TA of a plate heat exchanger, in which sanitary water will be heated, is used on the simplest models of TA.

- Purchase of a heat accumulator with a built-in DHW system - it can be implemented using either a separate heat exchanger (coil) or according to the “tank in tank” scheme.

You can, of course, also purchase an indirect heating boiler separately, but I believe that this can only be done if you have the necessary space in your boiler room.

A heat accumulator is another way to increase the time between fuel fillings in the boiler. In addition, TA can be used in systems with solar collectors and heat pumps. Most often, TA is used as a replacement for long-burning boilers. The alternative is certainly interesting and worthy of your attention. This concludes my story. I look forward to your questions in the comments.

Heat accumulator, its device and principle of operation

Heat accumulator, its device and principle of operation. What is a heat accumulator? Why do you need a heat accumulator? Materials of the water-containing capacity of the heat accumulator. Heat accumulator and hot water supply.

Solid fuel boilers are used for heating suburban facilities if other types of fuel are not available or unreasonably expensive. For each heating season, the owner of the cottage has to prepare the necessary supply of firewood and coal, the volume of which depends on the area of the object and the quality of its thermal insulation, as well as the severity of climatic conditions in the region of residence. Most models of solid fuel boilers can provide a comfortable temperature in the house if they are heated twice a day at a strictly defined time. If you shift the ignition time of the fuel in the combustion chamber of the unit, then it becomes cold in the living room. An exception is long-burning boilers, which can maintain the required temperature in the house for several days. The same result can be achieved from a conventional solid fuel boiler, if an additional unit is included in the heating system, capable of accumulating excess heat generated by the unit when burning a portion of fuel. Such nodes include buffer tanks or heat accumulators, which are also called drives.

Installing a heat accumulator allows you to:

- organize boiler maintenance at a convenient time of the day,

- increase the time between successive fuel loads without reducing the comfort of living in the house,

- optimize house maintenance costs by reducing purchases of solid fuels.

The use of solid fuel boilers in conjunction with buffer tanks allows you to reduce the cost of solid fuel at times, while ensuring the required level of comfort in the house. The return on the installation of a storage tank can be significantly increased if intelligent controllers and sensors are used in the operation of the heating system. When the set temperature values are reached in the premises of the house, the supply of coolant to the heating devices is stopped.

The heat released by the boiler that continues to operate is accumulated in the buffer tank, and then it is given off to the cooled coolant, which begins to circulate through the system, bypassing the burned-out boiler. The larger the volume of the buffer tank, the longer the house will be heated due to the thermal energy accumulated in it.

The advantages of using a thermal storage tank in the heating system of a country house connected to several heat generators

Heat accumulator for heating boilers: device, types, connection principles

Installation of a heat accumulator is necessary to increase the performance of a solid fuel boiler and reduce fuel consumption.

When using a gas boiler, we do not need to independently maintain a certain temperature in the heating circuit - this is done by automation. But everything changes when a solid fuel boiler is installed in the house. The fuel in it burns unevenly, which leads to cooling or overheating of the heating system. A heat accumulator for heating will help to compensate for these fluctuations and stabilize the temperature in the circuit. A capacious storage tank will be able to retain an excess of thermal energy, gradually giving it to the heating system.

In this review, we will look at:

- How do heat accumulators for heating systems work;

- How to calculate the required volume of the battery tank;

- How are storage tanks connected?

- The most popular models of thermal storage devices.

Let's go through these points in more detail.

The principle of operation of heat accumulators

If you install a solid fuel boiler in the house, there will be a severe need to regularly add new portions of firewood. It's all about the limited volume of the combustion chamber - it cannot accommodate an unlimited number of logs. Yes, and systems for their automatic supply have not yet been invented, if we do not take into account pellet boilers with automation. In other words, you will have to monitor the operation of the heating system yourself.

These boilers develop maximum power at the moment when firewood blazes merrily in them. At this point, they give a lot of extra energy, so users dose the firewood carefully, putting them in one log at a time. Otherwise, the house will be too hot. There is nothing good in this, because because of this, the number of approaches increases, which is already high. The problem is solved with the help of a heat accumulator.

A thermal accumulator for heating is a storage tank in which a hot coolant accumulates. Moreover, energy is given to the heating circuit in a strictly dosed manner, which ensures temperature stability. Due to this, households get rid of temperature fluctuations and frequent approaches for laying firewood. Accumulation tanks are able to accumulate excess heat energy and smoothly release it to the heating circuits.

Let's try to explain the principle of working on the fingers:

The simplicity of the design of the thermal accumulator not only increases the reliability of the unit, but also simplifies repairs and scheduled maintenance.

- The heating boiler installed in the heating system with a heat accumulator is loaded with firewood and produces a large amount of thermal energy;

- The received energy is sent to the thermal battery and accumulates there;

- At the same time, with the help of a heat exchanger, heat is taken in for the heating system.

A buffer tank for heating (aka a heat accumulator) operates in two modes - accumulation and return. In this case, the power of the boiler may exceed the required heat output for heating the home. While firewood is burning in the firebox, heat will accumulate in the thermal accumulator. After the logs go out, energy will be taken from the battery for a long time.

The heat accumulators of Lazybok for hotbeds and greenhouses are arranged in approximately the same way - during the day they accumulate heat from the sun, and at night they give it away, warming the plants and preventing them from freezing. They just look a little different.

Heat accumulators for heating systems are also necessary if solar panels or heat pumps are used as a heat source. The same batteries cannot provide heat around the clock, since at night their efficiency drops to zero. During daylight hours, they will not only heat the house, but also accumulate thermal energy in the storage tank.

Heat accumulators can be useful when using electric boilers . Such a scheme justifies itself on a two-tariff payment system. In this case, the system is configured so that heat is accumulated at night, and heat is released during the day. Thanks to this, consumers have the opportunity to save money on electricity consumption.

Varieties of heat accumulators

The heat accumulator for the heating system is a capacious tank equipped with solid thermal insulation - it is she who is responsible for minimizing heat loss. With the help of one pair of pipes, the battery is connected to the boiler, and with the help of another pair - to the heating system. Also, additional pipes can be provided here for connecting a DHW circuit or additional sources of thermal energy. Let's look at the main types of heat accumulators for heating systems:

In the presence of a circulation pump, it becomes possible to use several buffer tanks at once, which allows you to evenly heat several rooms at once.

- Buffer tank - is a simple tank, devoid of internal heat exchangers. The design provides for the use of the same coolant in the boiler and batteries, at the same allowable pressure. If it is planned to pass one coolant through the boiler, and another through the batteries, an external heat exchanger should be connected to the heat accumulator;

- Heat accumulators for individual heating with lower, upper or several heat exchangers at once - such heat accumulators allow you to organize two independent circuits. The first circuit is a tank connected to the boiler, and the second is a heating circuit with batteries or convectors. The heat carriers do not mix here, in both circuits there may be different pressures. Heating is carried out using a heat exchanger;

- With a flow heat exchanger of the DHW circuit or with a tank - for organizing hot water supply. In the first case, water can be consumed all day and evenly. The second scheme provides for the accumulation of water in order to quickly return it at a certain time (for example, in the evening, when everyone takes a shower before going to bed) - indirect boilers that accumulate water are arranged in a similar way.

The design of heat accumulators for heating can be very different, the choice of the appropriate option depends on the complexity of the heating system, its characteristics and the number of hot coolant sources.

Some heat accumulators are equipped with heating elements with thermostats, which makes it possible to provide consumers with heat at night, when the coolant has already cooled down, and there is no one to throw firewood into the furnace. They are also useful when using heat pumps and solar panels.

Calculation of the volume of the heat accumulator

We have come close to the most difficult issue - to calculate the required volume of the heat accumulator. To do this, we will use the following formula - m=W/(K*C*Δt). The letter W denotes the amount of excess heat, K is the efficiency of the boiler (indicated as a decimal fraction), C is the heat capacity of water (heat carrier), and Δt is the temperature difference, determined by subtracting the temperature of the heat carrier on the return pipe from the temperature on the supply pipe. For example, it can be 80 degrees at the outlet and 45 degrees at the return - in total we get Δt = 35.

First, let's calculate the amount of excess heat. Suppose that for a house of 100 square meters. m. we need 10 kW of heat per hour. The burning time on one bookmark of firewood is 3 hours, and the boiler power is 25 kW. Consequently, in 3 hours the boiler will generate 75 kW of heat, of which only 30 kW must be sent for heating. In total, we have 45 kW of excess heat left - this is enough for another 4.5 hours of heating. In order not to lose this heat and not to reduce the amount of loaded firewood (otherwise we will simply overheat the system), you should use a heat accumulator.

As for the heat capacity of water, it is 1.164 W * h / kg * ° C - if you do not understand physics, just do not go into details. And remember that if you use a different coolant, then its heat capacity will be different.

Having carried out the necessary calculations, using our advice, you can easily choose a model that most accurately satisfies all your requests.

In total, we have all four values \u200b\u200b- this is 45,000 W of heat, the efficiency of the boiler (suppose 85%, which will be 0.85 in fractional terms), the heat capacity of water is 1.164 and the temperature difference is 35 degrees. We carry out calculations - m \u003d 45000 / (0.85 * 1.164 * 35). With these figures, the volume is 1299.4 liters. We round up and get the capacity of the heat accumulator for our heating system equal to 1300 liters.

If you can’t do the calculations yourself, use special calculators, auxiliary tables or the help of specialists.

Wiring diagrams

The simplest scheme for connecting a heat accumulator to a solid fuel boiler involves the use of the same coolant at equal pressure in the boiler and the heating system. For these purposes, the simplest storage tank without heat exchangers is suitable. Two pumps are installed on the return pipes - by adjusting their performance, we will ensure temperature control in the heating system. There is a similar scheme using a three-way valve - it allows you to control the temperature by mixing the hot coolant and the cooled coolant from the return pipe.

Heat accumulators with a built-in heat exchanger are designed to work in heating systems with high heat carrier pressure. To do this, heat exchangers are located inside them, connected through a circulation pump to the boilers - this is how a supply circuit is formed. The internal capacity of the storage tank with a second circulation pump and batteries forms a heating circuit. Both circuits can circulate different heat transfer fluids, such as water and glycol.

The scheme of a solid fuel boiler with a heat accumulator and a DHW circuit allows for the supply of hot water without the use of double-circuit equipment. For this, internal flow heat exchangers or built-in tanks are used. If hot water is needed throughout the day, we recommend buying and installing a heat accumulator with a flow exchanger. For peak one-time consumption, batteries with hot water tanks are optimal.

Bivalent and multivalent connection schemes have also been developed - they provide for the use of several heat sources at once for heating operation. For this, heat accumulators with several heat exchangers can be used.

Popular Models

It's time to deal with the most popular models of heat accumulators for heating systems. We will consider the products of domestic and foreign manufacturers.

The manufacturer of Prometheus heat accumulators is the Novosibirsk company SibEnergoTerm. It produces models with a volume of 230, 300, 500, 750 and 1000 liters. The equipment warranty is 5 years. Heat accumulators are endowed with four outlets for connection to heating and heat sources. For the conservation of the accumulated energy, a layer of thermal insulation made of mineral wool is responsible. Working pressure is 2 atm., Maximum - 6 atm. When buying equipment, consider its dimensions - for example, the diameter of a 1000-liter model is 900 mm, which is why its body may not fit in standard doorways 80 cm wide.

The price of the presented heat accumulator for heating systems varies in the range from 65 to 70 thousand rubles.

Another capacious heat accumulator for 1000 liters of water. It is equipped with one or two smooth-tube heat exchangers, but lacks thermal insulation, which must be taken into account when installing it - it will have to be purchased separately. The case diameter is 790 mm, but if thermal insulation is added to it, then the diameter grows to 990 mm. The maximum temperature in the heating system is +110 degrees, in the DHW circuit - up to +95 degrees.

These heat accumulators are represented by modifications with six or ten connections. There are also terminals for temperature sensors on board. The capacity of the tanks is 960 liters, the working pressure is up to 3 bar. The thickness of the heat-insulating layer is 80 mm. The use of other liquids as a heat carrier, except for water, is not allowed - this applies to both circuits, and not just the heating circuit. If necessary, it is possible to connect several heat accumulators in series into a single cascade.

Homemade heat accumulators

Nothing prevents you from assembling a heat accumulator for a heating system with your own hands - for this you need to make calculations and draw a drawing, focusing on the required capacity. Tanks are constructed from sheet metal 1-2 mm thick, cut with a plasma cutter, cutting machine or welding machine. Heat exchangers are organized from metal straight or corrugated pipes. And in order to avoid rapid corrosion of the metal, it is necessary to purchase a magnesium anode. Basalt wool can be used as thermal insulation.

As a bonus, we present a detailed drawing of a heat accumulator with a capacity of 500 liters - this is enough to maintain the heating system in a small house.

Video

During the heating of the house, it often happens that during the daytime it is possible to generate excess heat, and at night it is not enough. There is also the opposite situation, in which it is more profitable to use heating at night. Such moments will help smooth out the heat accumulator for heating. But you need to know how to choose it correctly, install it and connect it to the system. You can find detailed information on this topic from this article.

When you need a heat accumulator

This simple element of the heating system in the form of an insulated water tank is recommended to be installed in such cases:

- for the most efficient operation of a solid fuel boiler;

- together with an electric heat generator operating at a reduced night rate.

For reference. There are also water heat accumulators for greenhouses, used to store solar energy received during the day.

The operation of solid fuel boilers has its own characteristics. The heat generator operates with high efficiency only when operating at maximum modes, if you shut off the air to lower the temperature in the furnace, then the efficiency also decreases. The homeowner also has a lot of worries about the frequency of burning, the firewood has burned out - you have to load new ones, it is extremely inconvenient to do this in the middle of the night. The solution is simple: you need a storage tank that accumulates the previously generated heat to use it after the firewood burns out in the firebox.

The opposite situation occurs with an electric boiler connected to the network through a multi-tariff meter. To save money, you need to get maximum heat at night, when the tariff is low, and do not use electricity during the day. And here the heat accumulator in the heating system will allow you to organize the optimal schedule for the operation of the heat source, giving out hot water to the system while the heat generator is idle.

Important. To work together with a heat accumulator, the boiler must have at least one and a half reserve in terms of thermal power. Otherwise, he will not be able to simultaneously heat the water in the heating system and the storage tank.

A similar situation with excess heat occurs in greenhouses, in the daytime they are even ventilated. In order to accumulate solar energy for use at night, you can use the simplest heat accumulator of Lezhebok to heat the ground. This is a black polymer sleeve filled with water and laid directly on the bed, it does not allow the soil to cool down at night. To absorb more heat, barrels of water, painted black, are placed inside the greenhouse.

Heat accumulator calculation

A container for the accumulation of thermal energy can be either purchased ready-made or made independently. But a natural question arises: what capacity should the tank be? After all, a small tank will not give the desired effect, and too much will cost a pretty penny. The answer to this question will help to find the calculation of the heat accumulator, but first you need to determine the initial parameters for the calculations:

- heat loss of the house or its quadrature;

- duration of inactivity of the main heat source.

Let us determine the capacity of the storage tank using the example of a standard house with an area of 100 m2, which requires an amount of heat in the amount of 10 kW to heat. Assume that the net downtime of the boiler is 6 hours, the average temperature of the heat carrier in the system is 60 °C. Logically, during the period of time while the heating unit is idle, the battery must supply 10 kW to the system every hour, for a total of 10 x 6 = 60 kW. This is the amount of energy that should be accumulated.

Since the temperature in the tank should be as high as possible, for calculations we will take a value of 90 ° C, domestic boilers are still unable to do more. The required capacity of the heat accumulator, expressed in mass of water, is calculated as follows:

- m = Q / 0.0012 Δt

In this formula:

- Q is the amount of accumulated thermal energy, in our case it is 60 kW;

- 0.0012 kW / kg ºС is the specific heat capacity of water, in more familiar units of measurement - 4.187 kJ / kg ºС;

- Δt is the difference between the maximum temperature of the coolant in the tank and the heating system, ºС.

So, the water accumulator should contain 60 / 0.0012 (90 - 60) = 1667 kg of water, which is approximately 1.7 m3 in volume. But there is one point: the calculation is made at the lowest temperature outside, which happens infrequently, excluding the northern regions. In addition, after 6 hours, the water in the tank will only cool down to 60 ºС, which means that in the absence of cold weather, the battery can be “discharged” further until the temperature drops to 40 ºС. Hence the conclusion: for a house with an area of 100 m2, a storage tank with a volume of 1.5 m3 is enough if the boiler is inactive for 6 hours.

It follows from the previous section that it will not be possible to get rid of an ordinary 200-liter barrel, unless its capacity is at least half a cube. This is enough for a house of 30 m2, and then not for long. In order not to waste time and energy in vain, it is necessary to

From the point of view of placement in the boiler room, it is better to make a rectangular container. Dimensions are arbitrary, the main thing is that their product is equal to the calculated volume. The ideal option is a stainless steel tank, but ordinary metal will do.

At the top and bottom, a do-it-yourself heat accumulator must be provided with nozzles for connecting to the system. So that the steel walls do not bulge outward with water pressure, the structure must be tightened with ribs or jumpers.

The battery tank must be well insulated, including from below. For this purpose, foam plastic with a density of 15-25 kg / m3 or mineral wool in slabs of at least 105 kg / m3 density is suitable. The optimal thickness of the heat-insulating layer is 100 mm. The resulting apparatus, filled with coolant, will have a decent weight, so a foundation will be required for its installation.

Advice. If you need a container for a gravity heating system, then you should install it yourself on a metal stand, not forgetting to insulate the lower part. The goal is to raise the tank above the level of the batteries.

Wiring diagram

After the tank is in place, it must be properly connected to the piping network. The most popular is the standard heat accumulator connection diagram shown in the figure:

To implement it, you will need 2 circulation pumps and the same number of three-way valves. Pumps provide circulation in separate circuits, and valves provide the required temperature. In the boiler circuit, it should not fall below 55 ºС in order to avoid the appearance of condensate in the solid fuel boiler, this is what the valve on the left side of the diagram does.

The heat carrier in the heating pipelines is heated depending on the need for heat, and therefore the connection of the heat accumulator on the other side is also carried out through the mixing unit. The valve can control the water temperature in automatic mode, focusing on the sensor or using a thermostat. One of the schemes of a heating system with a heat accumulator (buffer tank) is shown in the video.

Conclusion

A heat storage tank can make life easier for owners of solid fuel boilers. They don't have to worry about loading fuel at night, which is a big plus. And the heat generator itself will begin to work in an economical mode, developing the highest efficiency. As for electric boilers, then the benefit when installing the drive is obvious.

In most modern heating systems, there is an inherent defect that makes it impossible to effectively organize heating using a periodic heating boiler. The problem lies not in the principle of fuel combustion, although not everything is going smoothly there either, but in the organization of heat transfer from a heat source - a solid fuel combustion front into the air space of living rooms of a house or apartment. Heat accumulators are designed to compensate for losses caused by the periodic operation of the boiler. To be precise, a heat accumulator is necessary for any periodic heating boiler.

The device, proudly called a heat accumulator for heating boilers, is a tank of considerable capacity, in some cases reaching up to 10 tons of water, with a system of internal heat exchangers. What should the use of a heat accumulator give:

- Safe accumulation of excess heat generated by the boiler in the water flow of the coolant;

- To increase the duration of the heating-cooling cycle of the boiler plant, thereby simplifying its maintenance, freeing it from the need to start it at night or at an inconvenient time for oneself;

- To increase the efficiency of work and increase the resource of heating boilers.

Interesting ! The primitive design of the heat accumulator for heating boilers allows you to make it yourself, you only need a water tank, pipes for connection, valve equipment and a welding machine.

In addition to a solid fuel heating boiler, there is also a need to use a heat accumulator for systems based on electric heating boilers. In this case, the use of a heat accumulator is dictated by an artificial choice in favor of periodic heating, and only at night, when it is possible to use a more favorable preferential tariff.

The design of modern heating boilers for the sake of the manufacturer is maximally optimized in terms of costs and production costs. A modern heating boiler is made of thin sheet steel with minimal costs for scarce and expensive copper and nickel, and operates in the “potbelly stove” mode.

In his device there is not even a hint of a heat accumulator. Such a heating boiler, in principle, is not capable of accumulating thermal energy. Compare a modern pellet or coal boiler with the old, heavy cast iron boilers, or even better, with the device of an ordinary rustic stone stove. In the latter case, the function of a heat accumulator is most effectively performed by brickwork, which directly absorbs heat from the flame and evenly transfers it into the air of the room for 10-12 hours.

Therefore, a modern heating boiler is inefficient without a heat accumulator. A solid fuel unit will be indispensable in operation and will do without multi-ton heat accumulators if its device has a system for automatically loading fuel into the furnace and subsequent ash removal.

How does a heat accumulator work

The purpose of the heat accumulator is to provide additional thermal energy to the water heating circuit after the reduction or cessation of heat generation by the heating boiler. To do this, in a huge container there is a large amount of boiling water at a pressure of about 3 atm. A heat exchanger is soldered into the tank body, through which heat is “pumped” into the accumulator and re-extracted into the heating system. Often an additional heat exchanger is built into the tank in order to obtain hot water for the needs of the kitchen and bathroom.

The principle of mixing flows of different temperatures

To quickly heat up the room, the heat accumulator is disconnected from the circuit of the heated coolant with the help of a three-way valve. Only after heating the water flow in the pipes above 60 ° C, water is connected to the circuit from the store of the heat accumulator. And while the boiler is running, the heat goes in two directions: into the storage tank and into the heating radiators.

There are certain benefits to this approach:

- Rapid heating of the living space, and only after that, the excess heat is discharged into the heat accumulator;

- The mixing principle gives an efficient heat exchange;

- The water reserve in the heat accumulator is a strategic reserve for the boiler, thereby preventing its possible burnout in case of violation of water circulation in the heating plant.

Important ! In such a scheme, any non-ferrous metals that give an electrochemical pair with steel and aluminum should be excluded.

Ideally, the water circulating in the hot heat exchanger of the heating boiler should not mix with the heat carrier flowing throughout the heating system. Therefore, a different scheme is often used in heat accumulators - with hydraulic decoupling and flow separation.

System with hydraulic decoupling of thermal carriers

In this scheme, the heat accumulator plays the role of one of the elements of the heat supply circuit; it cannot be excluded from the flow. In fact, in the heat accumulator there is a constant transfer of heat from the allocated "hot" circuit of the heating boiler and the rest of the mass of water or heat carrier circulating in the heating system.

What does it give:

- The highly loaded heat exchanger of the heating boiler requires the use of special water purified from impurities and oxygen from the air. Only such water guarantees a long service life of the heat exchanger tubes and seals. The supply of the required amount of prepared water is stored in an additional boiler.

- By means of a special scheme of heated water from the heat accumulator tank, the temperature of the selected liquid can be easily controlled, which simplifies the heating control system.

The disadvantages include the need for additional devices - two pumps: coolant circulation and power supply systems. Sometimes a pair of devices is used for backup - a voltage converter and an electric battery for a heating boiler. Otherwise, a power outage can lead to a serious accident in the primary circuit.

A more complex and improved scheme involves the use of two independent heat exchangers combined in one heat accumulator housing. This is a more rational way of organizing the operation of a heat accumulator with a high degree of redundancy. It is he who can be recommended for those who want to make a heat accumulator for a heating boiler with their own hands.

Building a heat accumulator on your own

For the manufacture of a heat storage device, it is necessary to determine the thermal power of the battery. There is a certain methodology for building an accumulating system. The amount of water in the accumulator is taken on the basis of 30-40 liters of liquid for every 1000 W of boiler heat output. In this case, for a house of 100m 2 of heated area, a capacity of 350-400 liters will be required. The best option would be to use a ready-made boiler tank, with water level, pressure and temperature sensors.

If an admixing system is selected as a working scheme, which works properly even in the absence of special pumps, a three-position block valve will have to be additionally installed in the heating circuit.

Simpler schemes will require one or two heat exchangers to be installed in the tank

Important ! On the Web, it is often recommended to install copper heat exchangers from a twisted copper pipe 15-17m long and 15-20mm in diameter “through the light”. The recommendation has dubious prospects, since copper and iron corrode intensively in contact with hot water.

It is better to use a heat exchanger made of the same material as the container. This guarantees the normal quality of the weld when installing the heat exchanger. In addition, in the cavity of the heat accumulator it is better to use anode protection with magnesium electrodes, similar to electric hot water boilers. The outer walls of the tank - heat accumulator are sheathed with heat-insulating mats or mineral wool.

Promising options for heat accumulators

One of the interesting solutions was small-sized batteries that use fusible paraffins or silicone oils instead of water. Due to the significantly higher heat capacity, it became possible to use safe small-sized storage systems for electric boilers in apartment heating systems. Instead of a 300-liter heavy capacity, it is planned to use a two-section accumulator with a total volume of 50 liters of coolant, which has a thermal reserve of 15 kW / h.

For your information ! Most often, heat accumulators are used as a backup source of heat when growing vegetables in greenhouses, to quickly heat the room during a sharp cold snap or frost.

The inability to use relatively inexpensive natural gas as a source of energy for heating homes is forcing homeowners to look for other acceptable solutions. So, in regions where there are no particular problems with the procurement or purchase of firewood, solid fuel boilers come to the rescue. It also happens that the only alternative is electrical energy. In addition, new technologies are increasingly being used to direct solar energy for heating needs.

All of these approaches are not without significant drawbacks. So, they include unevenness, a pronounced periodicity of the supply of thermal energy. In the case of an electric boiler, the main negative factor will be the high cost of consumed energy. It is obvious that the inclusion of a special device in the general circuit that would accumulate currently unclaimed thermal energy and give it as needed would help to significantly increase the efficiency of the heating system, improve the efficiency, uniformity of its operation, and simplify operational operations as much as possible. It is this function that the heat accumulator performs for.

The main purpose of the heat accumulator of the heating system

- The simplest heating system with a solid fuel boiler has a pronounced cyclical operation. After loading firewood and igniting it, the boiler gradually reaches maximum power, actively transferring thermal energy to the heating circuits. But as the load burns out, the heat transfer begins to gradually decrease, and the coolant carried through the radiators cools down.

It turns out that during the period of peak heat generation, it may remain unclaimed, since a configured heating system equipped with thermostatic control will not take too much. But during the period of fuel burnout and, moreover, the idle time of the boiler, thermal energy will clearly be lacking. As a result, part of the fuel potential is simply wasted, but at the same time, the owners have to deal with loading firewood quite often.

To a certain extent, the severity of this problem can be reduced by installing a long-burning boiler, but it cannot be completely removed. The discrepancy between the peaks of heat production and its consumption can remain quite significant.

- In the case of an electric boiler, the high cost of consumed energy comes to the fore, which makes the owners think about maximizing the use of equipment during periods of preferential night tariffs and minimizing consumption during the daytime.

Benefits of using differentiated electricity billing

With a competent approach to electricity consumption, feed-in tariffs can bring very tangible cost savings. This is described in detail in a special publication of the portal dedicated to.

An obvious solution suggests itself - to accumulate thermal energy at night in order to achieve its minimum consumption during the day.

- Even more pronounced is the frequency of heat generation in the case of using solar collectors. Here, the dependence is traced not only on the time of day (at night, the flow is generally zero).

Incomparable peaks of heating on a bright sunny day or in cloudy weather. It is clear that it is impossible to directly make your heating system dependent on the current “whims” of nature, but you also don’t want to neglect such a powerful additional source of energy. Obviously, some kind of buffer device is required.

These three examples, for all their diversity, are united by one common circumstance - a clear discrepancy between the peaks in the production of thermal energy and its rational and uniform use for heating needs. To eliminate this imbalance, a special device called a heat accumulator (thermal storage, buffer tank) is used.

Hajdu heat accumulator prices

heat accumulator Hajdu

The principle of its operation is based on the high heat capacity of water. If a significant amount of it is heated to the required level during the period of peak receipt of thermal energy, then during a certain period this accumulated energy potential can be used for heating needs. For example, if we compare thermophysical indicators, then only one liter of water, when cooled by 1 ° C, can heat up a cubic meter of air by as much as 4 ° C.

A heat accumulator is always a volumetric reservoir with effective external thermal insulation, connected to the heat source circuit(s) and heating circuits. The simplest scheme is best considered with an example:

The simplest heat accumulator (TA) in design is a vertically located volumetric tank, into which four branch pipes are cut into from two opposite sides. On the one hand, it is connected to the circuit (KTT), and on the other hand, to the heating circuit distributed around the house.

After loading and ignition of the boiler, the circulation pump (Nk) of this circuit begins to pump the coolant (water) through the heat exchanger. From the lower part of the TA, cooled water enters the boiler, and heated water in the boiler arrives at the top. Due to the significant difference in the density of cooled and hot water, there will be no active mixing in the tank - in the process of burning the fuel bookmark, the HE will be gradually filled with hot coolant. As a result, with the correct calculation of the parameters, after the fuel is completely burned out, the tank will be filled with hot water heated to the calculated level. All the potential energy of the fuel (minus, of course, the inevitable losses reflected in the efficiency of the boiler) is converted into heat, which is stored in the HE. High-quality thermal insulation allows you to keep the temperature in the tank for many hours, and sometimes even days.

The second stage - the boiler is not working, but the heating system is functioning. With the help of its own circulation pump of the heating circuit, the coolant is pumped through pipes and radiators. The fence is made from above, from the "hot" zone. Intensive self-mixing is again not observed - for the already mentioned reason, hot water enters the supply pipe, cooled water returns from below, and the tank gradually gives off its heat in the direction from bottom to top.

In practice, during the combustion process of the boiler, the selection of coolant into the heating system, as a rule, does not stop, and the HE will accumulate only excess energy, which currently remains unclaimed. But with the correct calculation of the parameters of the buffer capacity, not a single kilowatt of thermal energy should be wasted, and by the end of the boiler furnace cycle, the TA should be “charged” to the maximum extent.

It is clear that the cyclical operation of such a system with an installed electric boiler will be tied to preferential nightly rates. The timer of the control unit will turn the power on and off at a set time in the evening and morning, and during the day the heating circuits will be powered only (or mainly) from the heat storage.

Design features and basic connection diagrams for various heat accumulators

So, a heat accumulator is always a volumetric tank of a vertical cylindrical design, which has highly effective thermal insulation and is equipped with nozzles for connecting the heat generation and consumption circuits. But the internal design may vary. Consider the main types of existing models.

The main types of designs of heat accumulators

1 – The simplest type of TA design. Direct connection of both heat sources and consumption circuits is implied. These buffer tanks are used in the following cases:

- If the same coolant is used in the boiler and in all heating circuits.

- If the maximum allowable coolant pressure in the heating circuits does not exceed that of the boiler and the HA itself.

In the event that the requirement cannot be met, the heating circuits can be connected via additional external heat exchangers

- If the temperature in the supply pipe at the outlet of their boiler does not exceed the permissible temperature in the heating circuits.

However, this requirement can also be circumvented by installing mixing units with three-way valves on circuits requiring a lower temperature difference.

2 – The heat accumulator is equipped with an internal heat exchanger located at the bottom of the tank. The heat exchanger is usually a spiral, twisted from stainless steel pipe, plain or corrugated. There may be several such heat exchangers.

This type of TA is used in the following cases:

- If the indicators of pressure and achieved temperature of the heat carrier in the heat source circuit significantly exceed the permissible values for the consumption circuits and for the buffer tank itself.

- If there is a need to connect several heat sources (according to the bivalent principle). For example, a solar system (solar collector) or a geothermal heat pump come to the aid of the boiler. At the same time, the lower the temperature difference of the heat source, the lower its heat exchanger should be placed in the HE.

- If a different type of coolant is used in the heat source and consumption circuits.

Unlike the first scheme, such a TA is characterized by active mixing of the coolant in the tank - heating occurs in its lower part, and less dense hot water tends upward.

In the diagram, a magnesium anode is shown in the center of the GA. Due to the lower electrical potential, it "pulls" ions of heavy salts onto itself, preventing the internal walls of the tank from overgrowing with scale. To be replaced periodically.

3 – The heat accumulator is supplemented with a hot water flow circuit. The entrance of cold water is carried out from below, the supply to the point of hot water intake, respectively, from below. Most of the heat exchanger is located in the upper part of the TA.

Such a scheme is considered optimal for conditions where the consumption of hot water is sufficiently stable and uniform, without pronounced peak loads. Naturally, the heat exchanger must be made of metal that meets the standards of food water consumption.

Otherwise, the scheme is similar to the first one, with direct connection of the heat generation and consumption circuits.

4 – Inside the heat accumulator there is a tank for creating a supply of hot water for domestic consumption. In fact, such a scheme resembles a built-in indirect heating boiler.

The use of such a design is fully justified in cases where the peak of heat generation by the boiler does not coincide with the peak of hot water consumption. In other words, when the household way of life that has developed in the house involves a massive, but rather short-term consumption of hot water.

All of the above schemes can vary in various combinations - the choice of a specific model depends on the complexity of the heating system being created, the number and type of body sources and consumption circuits. Please note that in most heat accumulators there are many outlet pipes spaced vertically.

The fact is that with any scheme inside the buffer tank, one way or another, a temperature gradient is formed (the difference in temperature difference in height). It becomes possible to connect the circuits of the heating system that require different temperature conditions. This greatly facilitates the final thermostatic control of heat exchangers (radiators or "warm floors"), with minimal unnecessary energy losses and reduced load on the control devices.

Typical schemes for connecting heat accumulators

Now you can consider the basic schemes for installing heat accumulators in the heating system.

| Illustration | Brief description of the scheme |

|---|---|

| The temperature regime and pressure are the same in the boiler and in the heating circuits. The requirements for the coolant are the same. A constant temperature is maintained at the outlet of the boiler and in the TA. On heat exchange devices, the adjustment is limited only by a quantitative change in the coolant passing through them. |

| The connection in the heat accumulator itself, in principle, repeats the first scheme, but the adjustment of the operating modes of heat exchangers is carried out according to a qualitative principle - with a change in the temperature of the coolant. For this, thermostatic mixing units, for example, three-way valves, are included in the circuit. Such a scheme allows the most rational use of the potential accumulated by the heat accumulator, that is, its “charge” will last for a longer time. |

| Such a scheme, with the circulation of the coolant in the small circuit of the boiler through the built-in heat exchanger, is used when the pressure in this circuit exceeds the allowable value in the heating devices or in the buffer tank itself. The second option is that different heat carriers are used in the boiler and in the heating circuits. |

| The initial conditions are similar to scheme No. 3, but an external heat exchanger is used. Possible reasons for this approach: - the heat exchange area of the built-in "coil" is not enough to maintain the required temperature in the body accumulator. – TA without an internal heat exchanger was already purchased earlier, and the modernization of the heating system required just such an approach. |

| Scheme with the organization of the flow supply of hot water through the built-in spiral heat exchanger. Designed for uniform consumption of hot water, without peak loads. |

| Such a scheme, using a heat accumulator with a built-in tank, is designed for peak hot water consumption, but not very positive. After spending the created stock and, accordingly, filling the container with cold water, heating to the required temperature can take quite a long time. |

| A bivalent circuit that allows you to use an additional source of thermal energy in the heating system. In this case, the variant with the connection of a solar collector is simplified. This circuit is connected to a heat exchanger at the bottom of the heat storage. Typically, such a system is calculated in such a way that the main source is the solar collector, and the boiler is turned on as needed, for reheating, in case of insufficient energy from the main one. The solar collector, of course, is not a dogma - there may be a second boiler in its place. |

| A scheme that can be called multivalent. In this case, the use of three sources of thermal energy is shown. The boiler acts as a high-temperature boiler, which, again, can only play an auxiliary role in the overall heating scheme. Solar collector - by analogy with the previous scheme. In addition, another low-temperature source is used, which, at the same time, is stable and independent of weather and time of day - a geothermal heat pump. The lower the temperature difference from the connected energy source, the lower the place of its connection to the heat accumulator. |

Of course, the diagrams are given in a very simplified form. But in fact, connecting a heat accumulator to complex, branched systems, with different heating circuits, and even receiving heating from sources of different power and temperature, requires highly professional design with engineering thermal calculations, using many additional adjustment devices.

One example is shown in the figure:

1 - solid fuel boiler.

2 - an electric boiler, which is switched on only as needed and only during the period of the preferential tariff.

3 - a special mixing unit in the high-temperature boiler circuit.

4 - solar station, solar collector, which on fine days can serve as the main source of thermal energy.

5 - heat accumulator, to which all circuits of heat generation and its consumption converge.

6 - high-temperature heating circuit with radiators, with regulation of modes according to the quantitative principle - only and the use of shut-off valves.

7 - low-temperature heating circuit - "warm floor", which necessarily provides for high-quality control of the heating temperature of the coolant.

8 - flow circuit of hot water supply, equipped with its own mixing unit for high-quality regulation of the temperature of domestic hot water.

In addition to all of the above, own electric heaters - heating elements - can be built into the heat accumulator. Sometimes it is beneficial to maintain a given temperature with their help, without, for example, once again resorting to unscheduled kindling of a solid fuel boiler.

Special additional heaters can be purchased separately - their mounting thread is usually adapted to the connection sockets available on many models of heat accumulators. Naturally, the connection of heating electricity will require the installation of an additional thermostatic unit, which will ensure that the heating elements are turned on only when the temperature in the heater drops below the level set by the user. Some heaters are already equipped with a built-in of this type.

Prices for heat accumulators S-Tank

Heat accumulator S-Tank

Video: Specialist's recommendations for creating a heating system with a solid fuel boiler and a heat accumulator

What to consider when choosing a heat accumulator

Of course, the selection of a heat accumulator is recommended to be carried out at the stage of designing a home heating system, guided by the calculated data of specialists. Nevertheless, the circumstances are different, and it is still necessary to know the main criteria for evaluating such a device.

- The first place will always be the capacity of this buffer tank. This value is calculated in accordance with the parameters of the system being created, the power of the boiler, the required amount of energy for the needs of heating, hot water supply. In a word, the capacity should be such as to ensure the accumulation of all excess heat at the moment, preventing its loss. Some rules for calculating capacity will be discussed below.

- Of course, the dimensions of the product and its weight directly depend on the capacity. These parameters are also decisive - far from always and not everywhere it is possible to place a heat accumulator of the required volume in a dedicated room, so the issue should be thought out in advance. It happens that large volume tanks (over 500 liters) do not fit into standard doorways (800 mm). When estimating the mass of the TA, it must be taken into account together in the entire volume of water of a completely filled device.

- The next parameter is the maximum allowable pressure in the heating system being created or already operating. A similar indicator of TA should, in any case, not be lower. This will depend on the wall thickness, the type of material used, and even the shape of the container. Thus, in buffer tanks designed for pressures above 4 atmospheres (bar), the upper and lower covers usually have a spherical (toroidal) configuration.

- Container material. Carbon steel tanks with anti-corrosion coating are cheaper. Stainless steel tanks are certainly more expensive, but their warranty period is also much longer.

- Availability of additional built-in heat exchangers for heating or hot water circuits. Their purpose has already been mentioned above - models are selected depending on the total complexity of the heating system.

- The presence of additional options - the possibility of embedding heating elements, installing instrumentation, safety devices - safety valves, air vents, etc.

- The thickness and quality of the external thermal insulation of the TA body must be evaluated so that you do not have to deal with this issue yourself. The better the tank is insulated, the naturally longer the “thermal charge” will be stored in it.

Features of installation of heat accumulators

Installing a heat accumulator implies compliance with certain rules:

- All connected circuits must be connected with threaded sockets or flanges. Welded connections are not allowed.

- The pipes to be connected must not exert any static load on the TA sockets.

- It is recommended to install shut-off valves on all pipes connected to the TA.

- Visual temperature control devices (thermometers) are installed at all used inputs and outputs.

- A drain valve must be installed at the lowest point of the TA or on the pipe in its immediate vicinity.

- On all pipes entering the heat accumulator, filters for mechanical water purification - “mud collectors” are installed.

- In many models, a pipe is provided on top for connecting an automatic air vent. If there is none, then the air vent must be installed on the topmost outlet pipe.

- In the immediate vicinity of the heat accumulator, it is planned to install a pressure gauge and a safety valve.

- It is strictly forbidden to make any independent changes to the design of the heat accumulator that are not specified by the manufacturer.

- TA installation should be carried out only in a heated room, excluding the possibility of liquid freezing.

- A tank filled with water can have a very significant mass. The platform must be able to withstand such a high load. Often, for these purposes, it is necessary to add a special foundation.

- No matter how the heat accumulator is installed, a free approach to the inspection hatch must be ensured.

Carrying out the simplest calculations of the parameters of the heat accumulator

As mentioned above, a comprehensive calculation of a heating system with several circuits for the production and consumption of thermal energy is a task that only specialists can do, since a lot of versatile factors have to be taken into account. But certain calculations can be done on your own.

For example, the house is installed. Its power generated at full fuel load is known. Experimentally determined the time of combustion of a full load of firewood. It is planned to purchase a heat accumulator, and it is necessary to determine how much volume will be required in order to guarantee the useful use of all the heat generated by the boiler.

We take the well-known formula as a basis:

W = m × s × Δt

W is the amount of heat required to heat up a mass of liquid m) with known heat capacity ( from) by a certain number of degrees ( Δt).

From here it is easy to calculate the mass:

m = W / (s × Δt)

It does not hurt to take into account the efficiency of the boiler ( k), since energy losses are somehow inevitable.

W=k× m × s × Δt, or

m = W / (k × c × Δt)

Now let's look at each of the values:

- m- the desired mass of water, from which, knowing the density, it will not be difficult to determine the volume. It will not be a big mistake to calculate from the calculation 1000 kg = 1 m³.

- W– excess amount of heat generated during the heating period of the boiler.

It can be defined as the difference between the energy values generated during the combustion of the fuel bookmark and spent in the same period on heating the house.

The maximum power of the boiler is usually known - this is a passport value calculated for optimal solid fuel water. It shows the amount of thermal energy generated by the boiler per unit time, for example, 20 kW.

Any owner always knows quite accurately how long the fuel bookmark burns out for him. Let's say it will be 2.5 hours.

Next, you need to know how much energy at this time can be spent on heating the house. In a word, the value of the need of a particular building for thermal energy is necessary to ensure comfortable living conditions.

Such a calculation, if the value of the required power is unknown, can be done independently - for this there is a convenient algorithm given in a special publication of our portal.

How to independently conduct a thermal calculation for your own home?

Information about the amount of thermal energy needed for heating a house is quite often in demand - when choosing equipment, arranging radiators, and when carrying out insulation work. The reader can get acquainted with the calculation algorithm, which includes a convenient calculator, by opening a publication on the link.

For example, heating a house requires 8.5 kW of energy per hour. This means that in 2.5 hours of burning the fuel bookmark, the following will be obtained:

20 × 2.5 = 50 kW

During the same period will be spent:

8.5 × 2.5 = 21.5 kW

W = 50 - 21.5 = 28.5 kW

- k- The efficiency of the boiler plant. It is usually indicated in the product passport as a percentage (for example, 80%) or as a decimal fraction (0.8).

- from is the heat capacity of water. This is a tabular value, which is equal to 4.19 kJ/kg×°С or 1.164 W×h/kg×°С or 1.16 kW/m³×°С.

- Δt- the temperature difference by which it is necessary to heat the water. It can be determined empirically for your system by measuring the values on the supply and return pipes when the system is operating at maximum power.

Let's say this value is

Δt \u003d 85 - 60 \u003d 35 ° С

So, all the values are known, and it remains only to substitute them into the formula:

m = 28500 / (0.8 × 1.164 × 35) = 874.45 kg.

The same approach can be applied if the volume of the heat accumulator connected to is calculated. The only difference is that it is not the burning time that is taken into account for the calculation, but the time interval of the reduced tariff, for example, from 23.00 to 6.00 = 7 hours. To "unify" this value, it can be called, for example, "boiler activity period".

To simplify the task for the reader, below is a special calculator that will allow you to quickly calculate the recommended volume of a heat accumulator for an existing (planned for installation) boiler.