Styrofoam is one of the most suitable materials with which you can insulate a wooden house both from the inside and outside.

The resulting sheathing will provide a high level of insulation, besides, if necessary, it can be sheathed from the inside with drywall.

House insulated with polyurethane

1 Features of foam as a material for insulation

The foam is presented in the form of gas-filled plastic, painted white, which has a low weight and low density.

Before you insulate your home with polystyrene foam and cover the wall of a wooden house with plasterboard from the outside or from the inside, you should familiarize yourself with the main characteristics of the foam.

Wall decoration with this material will allow the walls to gain good soundproofing characteristics. After that, the wall can be sheathed with drywall.

If you correctly sheathe the wall of a wooden house with foam from the outside, and preferably from the inside, then the insulation will be quite effective and reliable.

In addition, reviews of the presented material for insulation are mostly positive.

Styrofoam is practically a moisture-proof material, therefore, sheathing, insulation and finishing with its use from the inside or outside of a wooden structure must be carried out correctly.

Otherwise, when the walls are insulated from the inside (and subsequently sheathed with drywall), condensation may accumulate in the room, which will lead to an increase in humidity levels.

Innovative insulation - Barlight panels

In such a situation, it is better to think in advance about what kind of waterproofing can be used. For example, it will be correct to sheathe the wall from the outside with drywall.

1.1 Advantages and disadvantages

It is best to insulate a wooden house from the outside. However, in some cases it is impossible to carry out insulation in this way.

Finishing the insulated surface on the outside is also unacceptable. Good reviews indicate that the insulation of the internal walls of apartments with polystyrene foam is becoming increasingly popular among owners of city apartments.

Installation work using such a heater can be initiated at any time of the year.

This will not require special tools and construction scaffolds. If necessary, it will be possible to selectively insulate living rooms with foam plastic.

1.2 Is it worth it to insulate the house with foam from the inside?

Wall insulation with any material from the inside is not recommended by some experts. Insulation with foam is also highly undesirable in some situations. The fact is that foamed polystyrene has a number of disadvantages.

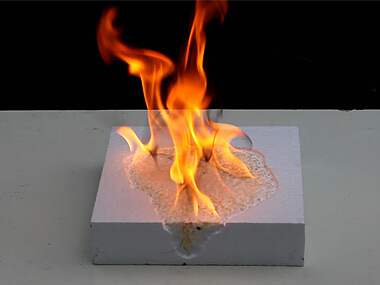

It is combustible and when it burns into the air, toxic substances are released, which are a danger to human life and health.

Some residents, when insulating the inner surface of the walls with foam, began to observe the appearance of condensate on them.

In addition, if you still decide to insulate the walls with such material, then you will need to make sure that a special layer of vapor barrier is created.

When insulated with this material, the internal dimensions of the room are significantly reduced. However, all these consequences can be eliminated at the initial stages of their occurrence, and therefore it can be assumed that the foam is a completely suitable material in order to use it to produce internal insulation.

In order to prevent accidental fire, you must carefully comply with all fire safety requirements in the interior.

The flammability group is almost always indicated on the product label, in addition, you can check it yourself.

To do this, you just need to set fire to a piece of foam, and if it burns intensively and drips, then its flammability level will be quite high. If it fades in a draft or wind, then the degree of combustibility will be lower.

When condensation occurs, the walls become damp, and, with a high degree of probability, mold may appear.

In order to avoid this, it is necessary to determine the location of the dew point. As a rule, this is the area where cold collides with heat, therefore, condensation forms there.

It is necessary to ensure that the dew point does not occur in the space between the insulation and the wall. To avoid this, the installation of insulation is carried out close to the wall, while there should be no gaps or gaps.

If a vapor barrier is used, it will be necessary to provide ventilation indoors. It must be of the forced type.

In this case, between the layer of vapor barrier material and the insulation, it is necessary to form a gap, presented in the form of a ventilation gap.

In this case, the apartment will not experience increased humidity. In most cases, when insulating walls with foam, a material is used whose layer thickness is on average 2 centimeters.

Then the area of \u200b\u200bthe interior will be reduced slightly. From this it follows that the insulation of the house with foam is quite feasible.

The cost of the presented material is quite acceptable, the low weight of the product contributes to the ease of installation work. Almost anyone can insulate walls with this material.

2 Reviews

As mentioned above, the reviews about the presented insulation are mostly positive.

Anton, 43 years old, Voronezh:

Before the onset of winter, I decided to insulate the balcony with polystyrene foam, since my apartment is corner and located on the windy side. I used standard plates and did all the installation work myself. Now the apartment is securely insulated. The material is excellent, I recommend it to everyone. I was recommended.

Vladimir, 36 years old, Khabarovsk:

I have been selling building materials and insulation for quite a long time. Styrofoam always sells very quickly, and many buyers ask to bring more. Excellent heater.

Alexander, 55 years old, Ufa:

I have been living in a private house for many years, but my heating system began to work intermittently. I didn’t have the money to repair and replace it, but I decided to insulate the walls with foam. Now the temperature in the house in the winter began to stay at a high level. Very happy with this heater.

2.1 How to sheathe walls with foam?

Despite the fact that such construction works do not differ in a high level of complexity, they are associated with a number of their subtleties.

In any case, like any of the applied methods of thermal insulation, this one should also begin with the stage of processing and preparing the inner surface of the walls.

If the walls of the house are built of brick, then they must be subjected to plaster without fail.

In the event that the house is built of concrete blocks, these works can be omitted. After the putty is completely dry, the walls must be primed.

After that, finishing and leveling is carried out by means of putty. For this purpose, it is best to use plumb lines of a vertical type.

Thus, the process of preparing the walls consists of several stages, which successively replace each other.

- The walls are cleaned from the old coating and facing materials.

- Surface defects (chips, notches, cracks) are searched for in the wall.

- Defects are eliminated with the use of plaster or putty.

- The final alignment is in progress.

Cracks with especially large dimensions can be repaired with mounting foam. After the surface of the walls becomes sufficiently even, they will need to be subjected to an additional primer again.

2.2 How to install insulation?

In order to carry out the installation of foam, you will need a certain number of umbrella dowels, equipped with hats in the form of parachutes.

In order to start the installation of foam plastic, which is in the form of plates, you will need mastic, which is presented in the form of a special glue.

It should be applied at the corners of the slab in small quantities or evenly applied to all edges.

In most cases, one layer of insulation is able to protect the house from the cold with a high degree of reliability.

Sometimes during installation, the glue is supplemented with special mechanical fasteners. For this purpose, umbrella dowels are used, equipped with a wide hat. They need to be used a few days after the foam has been glued to the wall.

That is, the adhesive composition must dry completely. It is important to remember that the laying of foam boards should be carried out from the bottom up.

In this case, each individual sheet should, with a maximum degree of density, adjoin to the neighboring one.

Plates need to be laid out with a checkerboard pattern. After the wall cladding with foam comes to an end, you will need to start processing the seams. In those joints that will be deep, with the help of glue, you need to place additional strips of heat-insulating material.

Small and inconspicuous gaps can be repaired with the help of ordinary polyurethane foam. It goes well with foam.

The remaining foam can be carefully cut off with a construction knife and rubbed with fine sandpaper. The most common film made using polyethylene can act as a waterproofing material.

In order to strengthen the internal structure of the walls and increase their degree of reliability, they can be reinforced. To do this, a mesh made of fiberglass must be installed on the insulated surface.

2.3 How to insulate the wall of the house from the inside with foam plastic? (video)

Do-it-yourself wall insulation with polystyrene foam from the inside has gained wide popularity, despite certain shortcomings. Manufacturers have taken into account the negative aspects of this material, and therefore, modern brands have become more environmentally friendly, and ingredients harmful to humans are prohibited for use. The solution to the question of how to insulate the walls in favor of expanded polystyrene is quite justified economically and practically from an operational point of view. Numerous reviews confirm its high efficiency as thermal insulation.

At its core, expanded polystyrene is foamed, i.e. saturated with gas, polystyrene and belongs to a large group of similar polymers, collectively known as foam. In this case, we mean polystyrene foam. There are 2 types of such plastic: pressed and extruded polystyrene foam. In the practice of private construction, the insulation of a residential building from the inside is carried out with an extruded (so-called non-pressed) polymer bearing the PSB brand.

Of the main positive qualities of the material, the following characteristics can be distinguished:

- excellent thermal insulation properties;

- sufficient resistance to deformation;

- operating temperature in the range from - 50º to + 72-78 ºС;

- water resistance;

- low specific gravity;

- ease of processing and installation.

Low thermal conductivity allows you to reduce the required thickness of the insulation. It has been established that the same protection is provided with such thicknesses of common materials: expanded polystyrene - 20 mm, wood - 16-28 mm, brick - 36-40 mm, mineral wool - 37-39 mm.

What limits the insulation with extruded polystyrene foam in living rooms? The risks of internal insulation with polystyrene are primarily associated with secretions that are dangerous for the human body when it is heated above 80º C. Combustion of the material is especially dangerous, because. toxic gases released can cause serious poisoning of the body.

That is why, when equipping your house or apartment, it is necessary to use polystyrene foam from well-known manufacturers, where the content of harmful components is minimized, and also not to place such insulation near heating appliances, stoves, fireplaces, etc. You can not use it in the steam rooms of baths and saunas.

Do not place Styrofoam near heaters

The disadvantages of any foam plastics include low mechanical bending strength and the ability to crumble under mechanical stress, which requires appropriate protective covers. In addition, the material is impervious to vapor, and therefore condensation on the polymer surface must be avoided.

For wall insulation with extruded polystyrene foam, several types of polymer can be used: Primaplex, Teplex, TenoNicol, Bateplex and others. Foamed plastic is sold in the form of plates (sheets) of different thicknesses and different sizes. When choosing a material, special attention is paid to the density of the foam, because. this characteristic determines the strength and thermal insulation properties, and they have an inverse relationship. Insulation with expanded polystyrene from the inside is usually provided by a polymer with a density of 25 kg / m³ (PSB-S-25, where "C" means self-extinguishing). The question of how to fix the insulation to the wall is solved with the help of an adhesive composition specially designed for this purpose.

Preparatory activities

When installing a wall insulation made of polystyrene foam with your own hands, you will need the following tool:

- hacksaw with fine teeth or string;

- sharp knife;

- scissors, rubber and metal spatula;

- paint roller;

- paint brush;

- measuring container for the preparation of glue;

- tape measure, metal ruler;

- plumb;

- construction level.

Thermal insulation of walls from the inside with expanded polystyrene includes the following main stages: preparation of the wall surface, fixing the expanded polystyrene to the wall, applying finishing coatings. The entire process can be seen on the video. At the preparatory stage, the following activities are carried out:

- Preliminary preparation. Insulation of the house begins with a thorough cleaning of the surface of the walls. It is necessary to remove the previous coating, especially paints and varnishes. This is important because the solvents present in such coatings are capable of destroying the expanded polystyrene. A complete revision of the condition of the wall surface is necessarily carried out, and, if necessary, large damages are repaired, large gaps can be filled with mounting foam.

- surface leveling. A smooth wall is an important condition for high-quality interior decoration. In the case of brickwork, plastering will be required, and in the presence of concrete walls, you can do without it. In any case, pre-treatment involves fine leveling. It is provided in the following order. An acrylic primer is applied to the surface of the wall, for which you can use a paint roller. After drying for 21-24 hours, all irregularities on the surface are eliminated with the help of a putty composition. Surface preparation is completed by applying another primer layer. An antifungal ingredient is usually added to the composition of the finishing primer.

Insulation installation

After the alignment of the wall is completed, the question is how to fix the polystyrene foam. In the general case, the following instructions for installing a heater can be offered:

- In order to fix the polystyrene boards on the wall, it is used special adhesive mixture. The composition is purchased in dry form and is prepared by mixing with water immediately before finishing work. The density of the adhesive must be optimal.

- The adhesive can be applied with a brush or roller to the surface of the wall or applied to the corners and along the edge of the polymer sheet.

- Installation of plates starts from the bottom. Previously, they are cut to size, for which they are applied to a dry wall. Cutting polystyrene foam is done using a well-heated string or a hacksaw with small teeth.

- Having installed the first row along the entire wall, you can start laying the next row. The plates in it are displaced relative to the lower sheets in such a way that the seam between the sheets of the first row falls in the middle of the upper plate.

- Drying of the adhesive composition is provided for 34-42 hours in natural conditions.

- It is advisable to additionally fix the installed insulation with dowels. To do this, the wall is drilled directly through the plastic, after which the plastic dowel is hammered. Thermal insulation is attached using self-tapping screws. Large polystyrene sheets are fixed at 6 points: in all corners and 2 dowels in the middle.

- Seam sealing. If the seams between the sheets exceed 30 mm, then pieces (trimmings) of polystyrene foam are glued into them. Finally, all seams are filled with mounting foam, which should not contain toluene, which can dissolve plastic. The excess mass is cut off with a knife, and then the seams are processed with an adhesive composition.

Final stage

Thermal insulation made of expanded polystyrene is covered on top with a layer that performs a protective and decorative function. The final stage includes the following works:

- Applying a reinforcing layer. Mechanical protection of the foam and improved adhesion is achieved by laying a reinforcing fiberglass mesh over the insulation. It is attached to the thermal insulation boards with an adhesive mass. A special grout is applied over the reinforcing layer. After waiting for it to completely solidify, grinding should be carried out using an emery cloth.

- The imposition of protective coatings. The next step is laying waterproofing and vapor barrier. Waterproofing is applied, as a rule, only in rooms with high humidity (bathrooms, kitchen, toilet). Vapor barrier in the form of a rolled material with a layer of foil is necessary for all rooms in order to prevent the accumulation of condensate on the surface of the thermal insulation.

- Wall plastering. Most often, the finishing coating of walls inside the house involves the imposition of a plaster mixture. It can then be painted or wallpapered. The plaster is applied using beacons, which makes it possible to ensure the evenness of the wall. After the plaster composition has dried, it is recommended to apply a finishing primer, which will finally eliminate all defects.

Internal insulation of walls with expanded polystyrene enjoys well-deserved popularity and is widely used in all regions of the country. The material has excellent thermal insulation properties, and with proper installation, it will provide heat in a house or apartment for a long time.

Do you want to get cozy and warm housing, the temperature in which does not depend on the vagaries of the weather? Then you should insulate the walls from the outside with foam. Don't know where to start and how to get started with this work? In this case, study this article - it will give you answers to your questions.

First, let's get acquainted with the material that will be discussed in the article. Styrofoam is a polymeric insulation produced in the form of white boards. The material has a pronounced granular structure, and each individual grain contains many voids filled with gas. It is their presence that gives the foam excellent thermal insulation qualities. For other material properties, see the table.

Table. Polyfoam - the main characteristics.

Important! When buying foam, pay attention to the fact that it has flame retardant additives, and the pores in the grains contain non-combustible carbon dioxide.

The advantages of polystyrene include:

- low cost;

- good thermal insulation qualities;

- small mass;

- ease of processing and installation;

- unattractive to bacteria and fungus;

- high durability.

As for the shortcomings of the foam, there are two of them. The first is the combustibility of the material. The second is low vapor permeability, which, in the event of an error in the design or installation of insulation, can lead to mold on the main wall.

The main task performed by insulation is to shift the dew point outward. Consider three building options.

- In the first case, there is only a wall without any insulation. The dew point is located inside the material, there is a significant temperature difference between its outer and inner sides. As a result, a lot of heat escapes through the wall, condensation forms in the house, and the service life of the material drops significantly due to dampness.

- In the second case, the insulation is located from the inside. The dew point shifts to the area between it and the wall. Heat losses are significantly reduced, but dampness remains. There is also a risk of mold appearing between the insulation and the wall.

- In the third case, the insulation is located outside, the dew point is shifted beyond the wall of the house. The latter is now not subject to dampness and does not lose heat.

Styrofoam prices

Styrofoam

Preparing exterior walls for insulation

Construction work related to the insulation of the facade of the house with polystyrene foam begins with the preparation of the walls. They need to be cleaned, leveled, primed, etc. All these actions are described in more detail in the step-by-step instructions below.

Step 1. To work at a height exceeding human height, build scaffolding. You can make them yourself from the timber and boards available on the site, but it is safer to use factory-made products.

Scaffolding prices

Scaffolding

Step 2 Inspect the walls for various defects. Coat cracks and holes, chip off the build-up of mortar. Prepare openings for water and gas pipelines and other utilities.

Step 3 Treat the wall with a deep penetration primer. Since the house in the example is made of aerated concrete blocks, two layers will be required. For the first time, the primer must be diluted by adding water from a third to a half of the total volume.

Important! Primer treatment in two layers is necessary not only for aerated concrete, but also for other porous materials, such as foam blocks and sand-lime bricks.

Step 4 Apply a second coat of primer, but not diluted with water.

After completing the preparation, proceed to laying the polystyrene foam boards. In this case, their mounting on the wall will be combined - both glue and dowels with "umbrellas" are used.

The process itself will include:

- laying polystyrene foam for insulation on ordinary walls of the house;

- on window and door openings;

- at the corners;

- on the space under the roof of the cottage.

For all processes from this list, separate step-by-step instructions have been compiled, which can be found in the subsections of the article below.

Working with Regular Walls

Let's start warming the house from the outside with foam. Let's start with a relatively simple one - mounting the first row of polystyrene foam boards and laying them on ordinary walls.

Step 1. Measure how smooth the walls of the house you are insulating are, identify the presence of differences in thickness. To do this, use either a stretched thread or a laser level.

Step 2 Set a mark at the bottom of the wall and draw a line from it along which the first row of polystyrene foam plates will be laid.

Important! In this case, when insulating the walls from the outside, the foam is laid directly on the foundation - it is even enough for this. In other situations, install a special aluminum support profile before installing the EPS boards.

Step 3 Mix the adhesive for mounting the polystyrene foam insulation. To do this, dilute the dry mixture in water. Choose the proportions based on the instructions printed on the glue package. Stir the solution using a mixer or a drill with an appropriate nozzle, working at low speed.

Step 4 Prepare polystyrene boards for the first row of insulation. In this case, a cutout is created in each of them, as in the diagram below. Cutting polystyrene foam plates is carried out using a special table with a hot nichrome thread. In the absence of such equipment, use a hacksaw with a fine tooth.

Step 5 Apply adhesive to the first block. To start, make a thin strip around the perimeter by pressing the trowel into the Styrofoam. Then add more mortar, bringing the layer thickness to 25-30 mm. In the center of the block, apply several adhesive dots, their number depends on the area of the insulation element.

Application of the second layer, more voluminous. In the process of working with it, be careful - the glue should not get on the ends of the foam block

Prices for Ceresit glue

Glue Ceresit

Step 6 Perform a test laying of the styrofoam block. The purpose of the event is to find out what proportion of the total area is occupied by glue. To do this, lean the block against the wall, and then set it back. Depending on the thickness of the insulation layer, the adhesive contact area should be 40-60% of the total.

Step 7 On paper or directly on the wall, prepare the marks on which the polystyrene blocks will be placed. Lay the slabs in the same way as brickwork - the top row is shifted to the side relative to the bottom so that the vertical seams do not match. The allowable distance is from 15 cm, otherwise the seams will become "cold bridges". You can get acquainted with the layout of the foam blocks in the images below.

Step 8 Proceed with laying the first block - apply the adhesive on it as shown earlier, lean against the marked place and lean it. Then align the position of the product. This will help you with a thread stretched along the upper edge of the first row of blocks, and the usual building level.

Important! Use small pieces of Styrofoam as pads to support the first row of blocks.

Step 9 Following the same principle as in the previous step, lay the second, third and subsequent blocks of the first row.

Step 10 Then lay the remaining rows of foam insulation. You can read about how to do this at corners and openings in the following subsections of the article. Dock the blocks to each other tightly, fill the gaps with polystyrene foam glue, polyurethane foam or thin pieces of material.

Step 11 After the glue or mounting foam has dried, with which you filled the joints between the blocks, cut off the excess with a construction knife.

Step 12 Use the rule to determine how even the insulation layer turned out. Protruding areas grind with a special grater.

Corner insulation

Installation of insulation at the corners occurs according to the following scheme - on one side, the block extends beyond the wall boundary at a distance equal to the thickness of the block installed on the second side. On the next row, the order of location of the foam insulation elements is reversed. By a similar principle, blocks are installed on internal corners. For a better idea, check out the images below.

Now let's look at how the installation of foam blocks on the corners of the building actually takes place.

Step 1. Mark one of the foam blocks. Select the part that will go beyond the border of the wall at the corner and the part that will be glued to the surface.

Step 2 On the part of the block that is glued to the wall at the corner, apply the mortar mixed earlier. Perform this operation carefully - the glue should not get on the other part of the product that you previously separated using the markings.

Step 3 Lean the block against the wall so that the adhesive adheres to the surface. Align horizontally and vertically, be sure to use the building level.

Prices for building levels

Building levels

Step 4 Measure how long a block you will need to install on the other part of the corner. Cut off the excess with a fine-toothed hacksaw.

Step 5 Apply glue to the back of the foam and place the block on the other side of the corner. Connect it tightly to the product that you installed a few operations ago.

Step 6 Cut off the protruding part of the first block with a hacksaw. At the end, you should have a right angle without any defects. If there is a gap between the blocks, then cover it with special glue for polystyrene foam or mounting foam. By the same principle that was outlined in this instruction, work with the rest of the external and internal corners of the building.

Insulation of window / door openings and walls next to them

To begin with, consider the principle by which the walls are insulated near the doorway. Here the main task for you will be to provide enough space for opening and closing. There are two options for mounting the frame and door.

- The door is installed flush with the outer side of the insulation layer. In this case, you need special fasteners for it and supports in the form of channels. You can see the diagrams of their installation in the image below.

- The door is installed flush with the main wall. As a result, it turns out to be "drowned" in the insulation. To ensure the normal opening of the door, the polystyrene foam at the edges of the opening has to be filed.

Imagine the process of laying insulation near the doorway in the form of step-by-step instructions. In this case, the option is considered with the installation of the frame and the door itself at a level with the main wall.

Step 1. Pick up the right number of blocks and file them from the edge with a regular hacksaw with fine teeth.

Step 2 Install a frame in the doorway, if this has not been done before.

Step 3 Degrease the surface of the door frame.

Step 4 Prepare the required number of profiles for thermal insulation of openings. Unpack them, measure and cut. In this case, the edges of the profile adjacent to the corners of the openings must be cut at an angle of 45 °.

Step 5 Remove the protective tape from the adhesive layer of the profile and fix it on one side of the opening. Make sure the profile fits snugly against the surface.

Step 6 Glue the profiles on the other sides of the opening in the same way. In the corners, join them tightly to each other with cuts made at an angle of 45 ° in one of the previous stages of work.

Step 7 Prepare fiberglass strips. Their width should be equal to the thickness of the insulation layer plus 10 cm for fastening to the main wall. In this case, the strip is cut off from a single mesh roll.

Step 8 Along the perimeter of the opening, apply a strip of adhesive mixture 10 cm wide on the wall.

Step 9 Rest a strip of fiberglass mesh with one of the edges on the glue applied in the previous step. Press the material against it, literally “drown”.

Step 10 From above, apply another layer of glue to the part of the mesh leaning against the wall.

Step 11 Repeat the previous mesh operations for the other sides of the doorway.

Step 12 Install foam blocks with cut edges around the perimeter of the opening.

The situation with window openings is approximately the same - the block itself with a frame and glass can be installed both in the depth of the opening and on its edge. In the first case, a gap appears between the outer layer of insulation and the window, which is closed by narrow strips of foam. They are laid on the glue in the inner surfaces of the opening.

In the second option, the window is mounted on the edge of the opening, with the frame adjacent to the insulation layer on the outer wall. This method is more effective in terms of thermal insulation.

It is also worth saying that the joints of the polystyrene blocks should not coincide with the joint of the window block with the opening. Therefore, along the perimeter, the insulation is installed in the form of products with L-shaped cutouts. There are two options for how to do this, and they are presented in the images below.

The process of insulating walls with foam plastic near window openings is in many ways similar to that for a doorway. Here is a step by step guide.

Step 1. Install the window block, move it closer to the edge of the opening and fix it well there.

Step 2 Remove the protective film from the frame and degrease the latter.

Step 3 Glue a special profile around the perimeter of the frame.

Step 4 Apply a 10 mm wide adhesive strip along the perimeter of the profile on the wall.

Step 5 On the glue applied in the previous step, fix the fiberglass strip according to the same principles as for the doorway.

Step 6 Cut out the blocks in accordance with the diagrams outlined in the images in this section of the article. Fasten around the perimeter of the opening.

Important! When fixing the foam plastic under the window opening, make a slight slope necessary to install the ebb.

As for the space under the roof, here the difference from working with ordinary walls is that it is necessary to pre-cut blocks with different and complex shapes from the foam.

Installation of mounting umbrellas on foam plastic

For a more reliable connection of the insulation layer with the main wall, mounting "umbrellas", also known as dish-shaped dowels, are used.

Step 1. Determine the length of the dowel you need. It consists of the thickness of the insulation layer (in this case it is 200 mm), the adhesive layer (15 mm), the length of the expansion part of the dowel (60 mm) and another 20 mm of reserve. Also decide which of the schemes shown in the image below, you will mount the fasteners.

Step 2 Unpack the plate dowels, check if the parameters of the product match those you need.

Step 3 Prepare a drill with a hole depth limiter, adjust the latter to the value you need.

Step 4 Mark the points for the plate-shaped dowels and drill holes there.

Step 5 Insert the leg of the dowel into the hole so that the head is flush with the surface of the foam. Then use a special nozzle on the drill and tighten the spacer part of the fastener, then close it with a protective cap.

In some dish-shaped dowels, the expansion element is not twisted, but clogged. You can see an example of how to work with them in the images below.

Some builders believe that dish-shaped dowels in foam insulation are "cold bridges." They deal with this problem in the following way: using a special cutter, they cut out a cylindrical recess in polystyrene foam, insert fasteners there and fix it. Then the dish-shaped dowel is closed with the foam cover cut earlier.

Prices for popular models of rotary hammers

Perforators

Video - Insulation of the facade of the cottage with polystyrene foam

Insulation reinforcement

On the installation of expanded polystyrene blocks, the process of wall insulation from the outside is not completed - the material must be protected with a reinforcing mesh and plaster mixture.

Step 1. Prepare a plaster-adhesive mixture of dry powder and water. Choose the proportions based on the recipe printed on the package. Mix the mortar with a construction mixer.

Step 2 Start with windows and doors. On the inner surface of their openings, apply a thin layer of plaster-glue mixture and level it.

Step 3 The reinforcing mesh laid on the inner surface of the openings in one of the previous sections of the article is pressed against the adhesive mixture and drowned in it. Smooth everything on top with a rectangular trowel.

Step 4 In exactly the same way as in the previous operation, press the mesh belonging to the previously installed profile to the adhesive layer and drown it.

Step 5 Repeat the previous three steps on all sides of the window opening.

Step 6 At the corners near the openings, apply stripes of the adhesive mixture at an angle of 45°. Then lay a reinforcing mesh on them and smooth it with a trowel. Such areas near the openings are called "kerchiefs".

Step 7 Measure the corner profile to the required length. Apply a layer of adhesive mixture along the outer perimeter of the window, then lean a profile with a mesh against it and the inner surface of the opening and smooth it with a rectangular trowel.

Step 8 By the same principle, install corner profiles on other surfaces of the window opening.

Step 9 Attach a small rectangle or square of reinforcing mesh to the inner corners of the opening, straighten and smooth with a glue mixture.

Step 10 Repeat steps two through nine for each individual window and door opening.

Step 11 Apply an adhesive solution around the perimeter of the house to the bottom of the insulation. Then attach a drop profile there. Install it so that there are no air cavities between it and the insulation. Control the process using the building level.

Step 12 Apply another coat of plaster over the mesh of the drip profile and smooth with a rectangular trowel.

Step 13 According to the same principles as described above, install the corner profile - apply an adhesive layer, attach the product to it, drown it in the net and smooth everything from above.

Step 14 Now proceed to reinforcing the entire surface of the walls. Make cuts from a roll with a mesh length corresponding to the height of the insulated walls of the house.

Step 15 On top of the polystyrene foam, apply a layer of plaster-glue mixture and smooth with a notched trowel.

Step 16 Lay a sheet of reinforcing mesh on top of the adhesive layer, press it and cover it with another layer of mortar on top. Carefully smooth everything - irregularities and cavities with air are unacceptable.

Step 17 In the same way, lay the next piece of mesh side by side. Between it and the previous one there must be an overlap of at least 100 mm.

Step 18 Let the glue mixture dry a little (but not completely!) and scrape off any bumps.

Step 19 Using the rule, search for concavities on the adhesive layer applied over the insulation. Then align them by adding a little more mixture in the right places.

Step 20 On the finally hardened adhesive mixture, make another leveling of the surface - puttying.

The easiest way to insulate a house is to sheathe it with foam. The material is inexpensive, installation is easy to do on your own, the energy-saving effect is obvious. And in order to protect such a skin from the harmful effects of the environment, you need to choose a suitable coating for it. Read more.

After the putty has hardened, the insulation of the walls from the outside with foam plastic can be considered complete. Then you just have to apply the finishing decorative finish in accordance with your tastes and preferences.

In order to live in a wooden frame house, it was possible to live comfortably not only in the summer season, but also all year round, you will need high-quality insulation of the walls of the house. It is best to insulate the walls with polystyrene foam (styrofoam). It’s worth saying right away that penoplex and polyurethane foam are the same thing, it’s just a kind of polystyrene foam. It is interesting that such material can be used both for a frame and a brick house, and the insulation is fastened in the same way both there and there.

Features, pros and cons of the “wet” and “dry” method of warming a frame house

As you might guess, wall insulation with polystyrene foam by the “dry” method assumes that the insulation will be applied immediately during the construction of the house, the voids are filled with a dry method.

This method has one significant drawback: dust particles that will fly off from the insulation can subsequently adversely affect human health. Penoplex and polyurethane in themselves are safe materials, they will not harm a person, but it’s still worth being careful.

The scheme of warming a house from a bar with the help of penoplex

The scheme of warming a house from a bar with the help of penoplex Usually, polyurethane foam is applied “dry” when the construction time is running out and the insulation for a frame or brick house needs to be fixed as quickly as possible. As for the brick structure, then in it the thermal insulation with foam plastic is usually carried out “wet”. What is meant by it?

Penoplex is first mounted in the grooves of the walls, and then it needs to be dried for 2-3 days.

If the weather conditions are unfavorable, then the time may well be needed even longer. Of course, in the conditions of extremely tight deadlines for the construction of a brick or frame house, such terms are a very big minus.

In general, here you need to choose: either mount the penoplex in a “dry” way and save time, or vice versa. But in any case, even from a purely technological point of view, “wet” foam insulation is preferable to “dry”. This must be taken into account.

Scheme of the device for dry insulation of a frame house

Scheme of the device for dry insulation of a frame house Preparation of walls for insulation with polystyrene foam

Wall preparation is the most important step. It includes the following work:

The walls of a frame house must be well prepared before insulation

The walls of a frame house must be well prepared before insulation - Wall alignment. It should be said right away that the walls of a frame or brick house should be actually perfectly even. The fact is that penoplex is a relatively fragile material. Any unevenness can simply lead to the fact that the insulation tiles will crack and the entire thermal insulation effect will be virtually destroyed. Experts recommend that plastering of walls be carried out in such a way that, as a result, the height difference (along with possible irregularities, chips, cracks) does not exceed 3 centimeters. This applies to both frame and brick houses;

- After plastering, it is not worth rushing to lay the foam plastic: the thermal insulation should adhere to the wall as best as possible. To do this, the surface of the latter should be slightly rough, in which case the material will lie better than if the wall is completely flat. Moreover, it should be borne in mind that polyurethane foam cannot simply be inserted into the crate of the facade of a brick or frame wooden house, as is the case with other types of material: it will be mounted using special glue. Naturally, it will be more problematic to glue insulation on a smooth glossy wall surface than not rough;

- If the walls of the building were painted on the outside with a coloring composition that has a zero vapor permeability index, then the layer of such paint must be completely cleaned (when the surface of a wooden frame or brick house is insulated with foam, the vapor barrier must be carefully monitored). After the paint layer has been cleaned, the surface must be primed without fail (a primer literally costs a penny in any construction market, so you definitely shouldn’t feel sorry for it). By the way, if we are talking about the internal insulation of a frame or brick house, then here it will no longer be necessary to prime the walls. But in any case, you should not forget about the vapor barrier;

- Checking whether the surface needs to be additionally primed is quite simple: you need to run your palm over the surface. If a chalk mark remains on the hand, then the surface must be primed again. Here, we can say, the following rule applies: there is never too much primer. Especially when it comes to the walls of a brick or frame house. And in itself, foam insulation, as noted above, does not imply fastening: only glue;

- If, upon manual contact, the surface crumbles, even if only slightly, then the surface must be cleaned again with a conventional brush, and then, again, a primer layer must be applied. Shedding is a rather serious problem, which can later lead to trouble.

After stripping the surface of the paint, it must be primed without fail.

Do-it-yourself insulation of a frame house with polystyrene foam

Insulation with polystyrene foam may involve fixing the material in the following ways:

Glue is used first:

After gluing the tiles, it is necessary to wait at least 3 days for the tile adhesive to set as securely as possible. By and large, it is not a problem to withstand such a period: it is unlikely that a person will quickly paste over all the outer walls of the building on their own.

After the glue has set, you can already proceed with the additional fastening of the insulation with dowels. The number of dowels is easy to calculate: for every square meter of wall area there should be at least 5 pieces of dowels.

As for the length of the dowel, the rule also applies here: they must enter the wall with their main part (up to the cap) by at least 5 centimeters. Less is impossible, since tiles of thermal insulation material can simply slide off.

In this case, then it is not recommended to use dowels at all: let the insulation rest on one glue. The dowels themselves should be centered with a slight indent.

What else you need to know when insulating a house with polystyrene foam:

Possible errors in insulation

Reinforcing mesh on polystyrene must be laid

Reinforcing mesh on polystyrene must be laid The most important mistake that people make when insulating houses is the lack of a reinforcing mesh between the laid insulation and the decorative part of the walls. Its presence is a guarantee that the heat-insulating material will last for a long time, and will perform all the functions assigned to it.

The mesh must be selected with a density index of 140 to 160 grams per 1 square meter. In this case, we are talking about frame houses, and not any others.

From above, it should also be covered with a second layer of adhesive, and the surface itself should also be almost perfectly flat. Here you can talk about several important nuances:

- The vertical stripes of the grid may not overlap, but the horizontal stripes must, and the overlap should be no more than 10 centimeters;

- The corners of the facade must be reinforced, for which either perforated plastic or a corner is used (if the corner is metal, then it must be galvanized to avoid corrosion in the future).

Another common mistake is that the insulation of the walls of the house is carried out very quickly, in haste. Often this is expressed in the fact that the glue is simply not allowed to dry completely and properly “grab” both the insulation itself and the walls of the building.

To strengthen the corners of the facade, perforated plastic is usually used.

Insulation of walls from the outside with polystyrene foam must necessarily involve holding the adhesive base for at least 3 days - this is even a law, not a rule.

Expanded polystyrene wall insulation is a very good material in itself, but its improper use can send all the work down the drain, especially when it comes to a wooden house.

Scheme of the principle of operation of insulation in the wall of the house

Scheme of the principle of operation of insulation in the wall of the house As for the finish, it can be very different. Today, for example, decorative plaster is often used. Of course, it is impossible to immediately apply plaster to the insulation: the reinforcing mesh indicated above must be available.

You should not forget about the primer in this case either. In general, any subsequent stage in the external insulation of the walls of the house should always involve a primer. If you do not use it, the wall will begin to crumble over time, the insulation will quickly become unusable, and all work will need to be done again.

On the other hand, initially you need to carefully calculate everything: any material for such work, its quantity, must be calculated with a margin of 10-15%. If then there is not enough material, then you will have to stop all work.

Video

You can watch a video that talks about it. how to properly insulate the walls of the house using polystyrene foam.

During the production of the material, polymer granules are mixed with a special type of blowing agent, which causes a corresponding chemical reaction. After that, the mixture is processed using an extruder under the influence of high temperature. This allows you to achieve homogeneity of the mixture due to the uniform distribution of its components.

At the last stage of production, plates of certain sizes are manufactured, which subsequently harden, turning into a high-quality insulation.

Advantages and disadvantages of the material

Consider the pros and cons of expanded polystyrene. The advantages of this material are as follows:

- High strength indicators;

- moisture resistance;

- Environmental friendliness;

- Acceptable price;

- Low vapor permeability;

- Fire safety. The material not only does not burn, but also does not participate in the spread of fire;

- Chemical resistance at a high level;

- Retention of the form during the entire service life.

The disadvantages of the material include:

- Quite a high price compared to mineral wool. This is a controversial drawback, since if we are not talking about rolled insulation, but about high-quality mineral wool, then its cost is several times higher than the price of expanded polystyrene.

- Destruction under the influence of ultraviolet radiation, and therefore the material must be hidden behind the skin.

- This insulation does not let the cold into the house, but also heat. This is true, but can this be considered a disadvantage, because many would like coolness in the summer heat, but in winter such a heater will not allow heat to go outside the room.

- The need to use a special composition, which is more expensive than tile adhesive. If the walls are insulated with polystyrene foam, without using a special adhesive composition, then you can not count on its high efficiency. According to statistics, plates “planted” on ordinary glue fall off after a few months. As a result, only "umbrellas" hold them, so it is not necessary to talk about reliable thermal insulation in such cases.

How to insulate walls with polystyrene foam

This material was developed back in the 50s of the last century. But, despite this, the insulation of facades with expanded polystyrene began to be carried out relatively recently. Today, this material is one of the most popular heaters, which is used not only in the construction of new buildings, but also in the restoration of old ones.

The use of expanded polystyrene is not limited to walls, it is also used for thermal insulation of roofs and floors. If we talk about the walls, then the external insulation of the building is more appropriate. Internal thermal insulation is carried out in cases where facade insulation with polystyrene foam is impossible. For this reason, both options for thermal insulation should be considered in more detail.

Features of external wall insulation

External thermal insulation can be carried out in two versions:

- When building a house.

- After building walls.

To insulate the facade, the thickness of the expanded polystyrene should be more than 10 cm. It is recommended to install thinner material in two layers. It should be remembered that the insufficient thickness of the heat insulator will significantly reduce the effectiveness of thermal insulation work.

Before insulating the walls from the outside, it is necessary to make their competent preparation. We are talking about leveling the surface, cleaning it from debris, dust, etc. Heat insulator sheets should be glued only on a prepared surface. For strengthening, we use "umbrellas" or dowels.

Let us consider in more detail the insulation of the facade with polystyrene foam:

- Glue sheets should start from the bottom, gradually moving up. This will prevent them from sliding down when the glue dries.

- In the process of work, it is possible to move the plates relative to each other, but not more than 10 cm.

- To provide additional fixation, it is necessary to install the base profile every 30 cm. In this case, its width should be equal to the thickness of the insulation sheets.

- For a tighter fit to the wall of the plinth profile, washers can be used.

- At the corners it is necessary to use the corner plinth profile.

- Having firmly fixed the sheets, glue should be applied to the wall and a reinforcing network should be installed. It needs to be slightly immersed in the adhesive layer, thereby ensuring the strength of the fastening.

- On top of the installed reinforcing mesh, it is necessary to apply a second layer of mastic, which should be carefully aligned.

- When the adhesive composition dries, the wall must be primed, after which it can be finished.

Wall insulation technology

As mentioned above, internal insulation is carried out if the thermal insulation of the facade is not possible. Most often this happens in cases where the building being reconstructed has a cultural value or the facade work was carried out relatively recently.

Plates for internal insulation should have a thickness of no more than 4 cm. You can also use thicker material, but then you need to be prepared for a significant reduction in the useful area of the building's premises.

Before work is carried out, the walls are also leveled and cleaned. Dowels are not required here.

Expanded polystyrene plates are mounted in accordance with the above scheme. Upon completion of these works, a crate is usually installed, which is sheathed with sheets of drywall.

The main mistakes made when insulating walls

Expanded polystyrene is one of the most popular heaters used recently. Do-it-yourself installation, home craftsmen often make gross mistakes, due to which they fail to create an acceptable level of thermal insulation. Let's look at the most common mistakes.