In order for bath procedures to bring only benefit and pleasure, two conditions are necessary:

- high level of temperature and humidity in the steam room;

- the presence of a sufficient amount of oxygen.

These seemingly mutually exclusive tasks are solved by ventilation in the bath in general and in the steam room in particular. Despite the fact that high humidity and temperature must be maintained in the steam room of a Russian bath, there is no way to do without access to fresh (cold) air: oxygen is processed by our lungs, partially burned out by the stove, besides, carbon monoxide gradually accumulates in the steam room (CO is the chemical formula carbon monoxide).

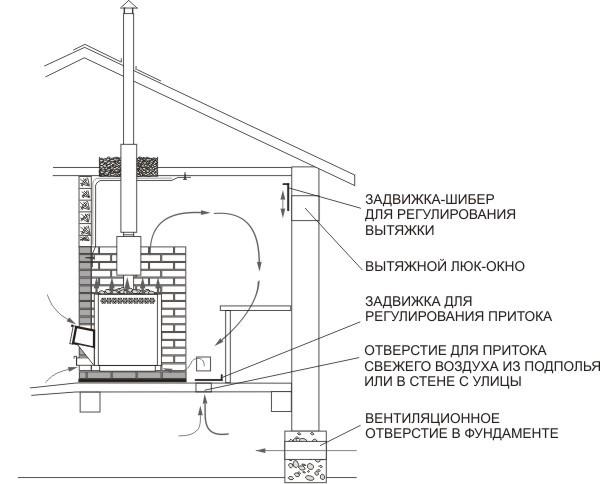

How to properly ventilate the bath. In the figure, red arrows show the movement of hot air, blue - cold

If you do not organize the replacement of "exhaust" air with fresh air, instead of improving health and increasing efficiency (this is why we go to the bathhouse), you can get, at best, lethargy, weakness and headache, and at worst - a hospital bed or even a place in a cemetery.

Properly arranged ventilation ensures air circulation, while oxygen is supplied in sufficient quantities, and carbon monoxide and carbon dioxide are released into the atmosphere. After the end of the bath procedures, with good ventilation, the vapors are actively removed outside the building, and the rooms, which previously had high humidity, dry out. If this aspect was not paid enough attention, after a couple of years in the steam room, and then in other rooms, the lining rots, the smell of mustiness and sweat appears and gradually increases, and the wood turns into dust. Now, I hope, it is clear whether ventilation is needed in the bath ...

Heating and ventilation of the bath. Please note that the exhaust outlet is located at a low height from the floor - as a rule, not higher than 50 cm. With this scheme, exhaust steam is emitted into the atmosphere. Moreover, the floor in the steam room warms up well.

Heating and ventilation of the bath. Please note that the exhaust outlet is located at a low height from the floor - as a rule, not higher than 50 cm. With this scheme, exhaust steam is emitted into the atmosphere. Moreover, the floor in the steam room warms up well. Ventilation in the bath is not needed only in one case: if it is all built of wood and has not been insulated anywhere - neither from the inside nor outside. In this case, air exchange occurs due to the fact that the wood "breathes". Even in this case, they speak of the presence of natural ventilation in the bath: any wood has pores and cracks through which the outflow / inflow of air takes place, the temperature and humidity are regulated. But if there is insulation or moisture / vapor insulation in the bath made of rounded logs, then the creation of additional ventilation holes is necessary.

There are three types of ventilation:

- Mechanical ventilation. In this case, the inflow and outflow of air masses occurs due to the artificially created air movement. Air parameters are controlled by technical means.

- Natural ventilation: circulation occurs due to the difference in pressure inside and outside the room. This method is only possible with "breathing" walls or thoughtfully arranged ventilation vents.

- Combined ventilation: the simultaneous use of the natural movement of air masses and technical devices (in the simplest case, fans).

The video below shows an option for combined ventilation.

In a specific case, 100 micron thick aluminum foil was used in the construction of the ventilation duct.

Bath ventilation device

In the simplest version, the ventilation system of a steam room or bath consists of two (sometimes more) holes in the walls and / or foundation: supply and exhaust. The whole trick is in choosing the location of these holes and in their sizes. Sometimes, to provide more active air exchange, fans can be installed.

Heating and ventilation of the bath. In the simplest case, the exhaust vent is located close to the ceiling.

Heating and ventilation of the bath. In the simplest case, the exhaust vent is located close to the ceiling. There is no single ventilation scheme for a bath: they are too different both in design features and in the materials of which they are made. But there are general rules and several most common schemes, adhering to which, you can choose the optimal ventilation for your case.

The dimensions of the ventilation openings are calculated based on the volume of the steam room: for one cubic meter of the ventilated area, the size of the openings should be 24 cm 2.

Despite the fact that the main task in the bath is to maintain high humidity in the steam room and a sufficient temperature level, it is impossible to make the ventilation holes too small: they will not provide the required level of air exchange. Exhaust ventilation openings must correspond to the size of supply air vents: if the proportions are violated, the air exchange will also be insufficient. In some cases, to speed up the removal of exhaust air and speed up the drying of the bath, you can make two exhaust holes.

To ensure the required air conditions when heating the steam room, special covers / plugs are made on the ventilation ducts, which can be opened / closed from the steam room, thereby regulating the humidity / temperature / air exchange. Generally speaking, the presence of plugs or covers on any ventilation opening facing the street is a must: in winter, cold air actively seeks into a warm room and the presence of covers or regulators that trap it is necessary.

Where can there be supply and exhaust openings

Most often, at least partially located in the steam room. In this case, the inlet is made near the stove at a distance not higher than 30 cm from the floor. The incoming cold air quickly heats up from the stove and rises up. This is a fairly popular, but not the best way to organize ventilation for a bath. Ventilation is much more effective when the inlet openings are located in the foundation under the floor (so that rodents do not penetrate through them, the openings are equipped with metal gratings). This option solves two problems at once: it delivers fresh air to the bath, and also effectively dries the floors and walls after the completion of the procedures. Floor boards, in this case, are not laid close, but with a small gap for free air passage. If you don't want to leave gaps in the floor (although this is very good for a bath), you can make several ventilation holes in the floor, covered with wooden gratings. In this case, the air movement will not be so active, more powerful fans may be needed, but the circuit will remain operational.

When planning the air inlets in the foundation, keep in mind that the air in the bath must come from the street, and not from the underground, otherwise it will have a musty smell. To organize air intake from the street, a box made of wood (often homemade), plastic or metal (ready-made) is placed in the hole, and it is also taken out near the stove. Typically, air inlets are located in an area that is protected from coals and embers by metal or asbestos sheet.

The ventilation holes in the foundation are foreseen at the planning stage. If the foundation is already ready, but there are no ventilation holes, you can make the floor ventilation in the steam room differently: lay the floor boards on the logs, but not close to each other, but with a gap of 0.5-1 cm. In the interval between the rough (earthen / concrete) floor and the finishing one, an outlet is arranged, which goes into a ventilation pipe, which takes the exhaust air out to the roof (but not to the attic). This option provides for the presence of only one inlet, which is usually arranged below the heater. The chimney under the floor is installed on the opposite side of the room (but not opposite, but obliquely).

It is impossible to make a chimney in the steam room from plastic ventilation boxes - they do not withstand high temperatures, but it is permissible to use them in a locker room or washing room.

With this ventilation scheme in the steam room, cold air warms up near the stove, rises up, then, cooling down, falls down, seeps through the cracks in the floor under the floor and is discharged through the outlet pipe. These two options effectively remove moisture after a bath, they can also be considered floor ventilation schemes in a bath.

Exhaust openings can be located on the opposite wall from the inlet (if both of these walls face the street) or on the same wall, but in the opposite corner. There is a scheme in which they are located at the top on the opposite wall (30 cm from the ceiling), sometimes they are located at the bottom (30 cm from the floor). If the exhaust outlet is at the bottom or on the same wall as the inlet, a fan is required to create airflow.

In order for ventilation in the bath to remain effective, you must not:

- make ventilation vents less than calculated;

- position the supply and exhaust openings one opposite the other - this is how the incoming air is almost immediately removed without giving up oxygen, a draft is formed, which is contraindicated for a bath.

Steam room ventilation schemes

Consider a few of the most common ventilation options in a steam room:

These are the most commonly used ventilation schemes for steam rooms in a bath; there are many more variations and combinations of them. Based on these four options for organizing ventilation, you can develop a scheme for your steam room.

Ventilation in the washing section of the bath

In a washing room, high humidity is a common thing, and so that the lining does not rot or an unpleasant smell does not appear, it is necessary to provide for ventilation of the floors. It is arranged in a similar way to floor ventilation in a steam room: an exhaust hole is made between the rough and final floor, which can be equipped with a fan. The chimney is led out to the roof.

With this scheme of floor ventilation in the washing compartment, the coldest exhaust air is removed, and the warmer one from the upper layers descends in its place. Thus, an increase in the comfort of the people staying here is also achieved.

The principle of ventilation in all other rooms of the bath is the same. You need to decide on the optimal ventilation system specifically for your conditions and choose / develop the most suitable scheme. Ventilation in the washing compartment differs only in that due to lower air temperatures, plastic ventilation ducts can be used here (which cannot be done in a steam room) and the fans can be installed not heat-resistant, but only tolerant of high humidity (moisture-proof).

Brick and Turkish bath ventilation

When planning a ventilation system for a brick bath, it is necessary to take into account that its efficiency should be several times higher than that of a wooden one. Indeed, in this case, you will have to dry not only the inner lining of the steam room / washing / changing room, but also the walls: brick is a very hygroscopic material. To remove all moisture, it is necessary that the inflow / outflow of air during drying is very active, and the vents have reliable dampers that allow you to regulate the intensity of air movement.

When ventilation is installed with its 100% humidity, the exhaust ventilation must also be very effective: for an hour of operation, it is necessary to provide six air changes in the room. In addition, it is necessary to provide for the possibility of draining condensate, which forms during cooling in large quantities. There are two ways to solve this problem: install an air dryer in the pipe, which leads the condensate into the sewage system, or provide a duct in the ventilation pipe to drain the condensate (it also goes into the sewer).

Output: it is necessary to plan ventilation at the design stage of the bath, placing supply vents in the foundation. If necessary, you can make vents in the finished walls, but this is quite troublesome and difficult.

A well-equipped ventilation system, all other things being equal, guarantees, firstly, a long service life of building and finishing materials used in the arrangement of the serviced premises, and secondly, the comfort and safety of visiting the latter for the user. In particular, the issue of arranging full-fledged and sufficiently effective ventilation is in the bathhouse, in view of the characteristic temperature and humidity conditions and additional requirements for such buildings.

Bath fan prices

bath fan

Video - Requirements for ventilation in the bath

The choice of the optimal type of ventilation system for servicing the bath is a topic for many hours of discussion. For example, there is natural ventilation. The costs of money, time and effort for its arrangement are minimal - the work literally boils down to drilling holes in the walls, installing boxes / pipes and valves / gratings.

Vent valve and grille

Vent valve and grille  Ventilation grilles for baths and saunas

Ventilation grilles for baths and saunas

However, it is impossible to use natural ventilation to service all the premises of the bath. Of course, one could save money, but the disadvantage of such a solution will become obvious with the arrival of the first winter: along with the influx of fresh air from the street, cold will come in, and the combination of frosty air with humidity is known to everyone - everything around will simply freeze. Therefore, natural ventilation in some rooms must be combined with other existing options in other bath rooms.

If the bathhouse is equipped with a washing room or even its own pool, natural ventilation will definitely not cope with the maintenance of such premises - you will have to equip an exhaust system. And in general, the presence of a forced inflow / outflow of fresh air will be useful both for visitors to the bath and for its premises. Recommendations for the optimal composition of the air exchange system are given in the table.

Table. Choosing a ventilation system for different rooms

| Premises | Recommended type of ventilation | Scheme | Description |

|---|---|---|---|

| Steam room, dressing room or relaxation room | Aeration should be understood as an organized natural air exchange. The option is most suitable for use in a bathhouse: air is supplied from the bottom of the stove (for other rooms - 25-30 cm above the floor), waste is discharged through an opening in the upper part of the room. The work of air exchange is based on elementary physical laws: cold air from the street displaces warm air masses, which have less weight, up the room. Aeration is ideal for use in rooms with high heat generation rates. The presence of additional moisture contributes to an even more pronounced increase in the efficiency of the system. |

||

| Washing room, bathroom, room with a swimming pool | The system is completed with a fan and, if necessary, with cleaning filters. Mechanical exhaust ventilation is ideal for use in the washroom, pool room and other wet and frequently visited bath areas. The mechanical hood provides effective removal of unpleasant odors and excess moisture, which makes the air in the served room safe and clean. It is impossible to use only exhaust ventilation - a rarefaction of air is formed. To compensate for the vacuum, an air flow from the street or other rooms is arranged. Along with this, the presence of supply ventilation will eliminate the likelihood of drafts. The supply ventilation system can be either natural or mechanical. In combination with mechanical exhaust ventilation, it is more expedient to use a mechanical supply system, because the possibilities of natural inflow may ultimately be insufficient to compensate for the resulting rarefaction. The mechanical supply ventilation is based on a blower fan. Additionally, it can be equipped with an air heater, which will eliminate inconveniences and solve the problems of ventilation of serviced premises in the cold season. Additionally, the supplied air can be humidified or cleaned using appropriate devices. A mechanical system is more complex in arrangement than its analogue, which operates according to the laws of physics: in addition to fans and air ducts, additional equipment and devices (diffusers, air distribution grilles, automation equipment, noise suppressors, etc.) can be included in the system. This gives an excellent opportunity to equip an air exchange system that fully meets the wishes of the user. |

In vestibules, warehouses and other premises of a similar purpose, a natural exhaust is made.

Regardless of the type of ventilation system chosen, the bath must have conditions for simple ventilation. Install adjustable windows in all areas where the location allows this.

Video - Types of ventilation systems

Instructions for self-calculation of air exchange

For the calculation, an elementary formula is used:

W (required volume of fresh / exhaust air) = k (coefficient indicating the rate of air exchange) x V (volume of the served room, determined by the product of the width of the room by the length and height).

That is, first you must calculate the volume of each room and find the required indicator of the volume of clean air for it (in calculations it is customary to denote Wpr, i.e. inflow) and a similar indicator of exhaust air (denoted as Ww, outflow). In this case, the multiplicity factors must be taken into account. The calculated values are rounded up - the last digit in the number must be 0 or 5.

Next, the summation of all Wpr is performed. A similar action is carried out for the found Ww. The amounts received are compared. If the total value of Wpr exceeds the total value of Wpr, it is necessary to increase the exhaust volume for rooms with a minimum air exchange value, if, on the contrary, increase the inflow by the missing value. That is, at the output, the sum of all Wpr should be equal to the total value of the found Ww.

The results of the calculations will make it possible to determine the optimal cross-sections of the installed air ducts and select the appropriate type of ventilation system. Thus, with the calculation of the volume of premises and other related data, no special problems will arise. For greater convenience of subsequent processing, enter the found values into a simple table, as in the example presented.

In the given example, the total value of Wpr is less than the sum of all found Ww by an indicator equal to 110 m3. In order for the balance to be observed as a result, it is necessary to provide an inflow of clean air in the missing amount. This can only be done in the dressing room. Thus, the value of 55 m3 for the dressing room, given in the table, must be replaced with an indicator of 165 m3. Then the balance will be met.

Start calculating the installed air ducts and drawing up the structure of the equipped ventilation system.

The ventilation system is designed in such a way that the air moves through the installed air ducts at the following speed indicators:

- ≤ 5 m / s in main ducts and ≤ 3 m / s in existing branches - for mechanical ventilation systems;

- ≤ 1 m / s - for natural air changes;

- 2 m / s - for natural air exchange directly in the steam room.

When choosing the cross-section of the air ducts, take into account the above indicators. As for the profile of the box / pipe, this moment is determined by the design features of the air exchange and the bath itself. For example, air ducts with a circular cross-section are easier to install than their rectangular "brothers", and the required connecting fittings for round air ducts are much easier to select.

The relationship between the diameter of the air ducts and other significant indicators is shown in the following tables.

For example, we will work with round ducts. We select the necessary sections according to the corresponding table, focusing, at the same time, on the indicators of the table Example of ventilation calculation.

The calculated air consumption turned out to be 165 m3 / h. The air flow at this flow rate should move no faster than 5 m / s. In accordance with the above table for round ducts, we select the cross-section according to the specified data. The tabular value closest to ours is 221 m3 / h. Air duct section - 125 mm.

Insulated air duct

Insulated air duct  Flexible air ducts

Flexible air ducts

In the same order, we determine the optimal cross-sections for all branches of the system in the serviced rooms, remembering that in them the air flow must move at a speed not exceeding 3 m / s (in vestibules and storerooms - 1 m / s, in a steam room - 2 m / s) sec):

- steam room: estimated Ww is 60 m3 / h, which requires the installation of an air duct with a section of 125 mm;

- shower room - Ww is 50 m3 / h, air moves at a speed of 3 m / s, an air duct of 100 mm is suitable;

- toilet - the indicators are similar to the shower room;

- pantry, vestibule, etc. - indicators (with the exception of air velocity) are similar to shower and toilet.

Important! In the shower room (washroom, room with a pool), an increased level of humidity is noted. When determining the cross-section of the duct for this room, it is necessary to make an amendment in the direction of increase (in this example - 125 mm).

For greater convenience, enter all the information received in the table. You can use the template below as an example.

Important note! In the above table, the exhaust volume exceeds the fresh air intake. This happened for the reason that the cross-sections were determined by the nearest flow rate, and the diameter of the air duct in the washing room was deliberately increased. In practice, such an approach will only be beneficial - the stock for outflow and inflow will not be superfluous.

SNiP 2.08.01-89. Residential buildings. Download file

Sanitary and Epidemiological Requirements for Residential Buildings and Premises. Sanitary and Epidemiological Rules and Norms SanPiN 2.1.2.1002-00. Download file

Building codes of the russian federation heating, ventilation and conditioning heating, ventilation and conditioning SNiP 41-01-2003. Download file

The cross-sectional area of the ventilation window is determined in accordance with the volume of the manned room: 24 cm 2 for each 1 m3.

It remains only to figure out the optimal height of the ventilation holes:

- for the flow of fresh air - on average 25-30 cm above the floor (in the steam room - near the stove);

- for exhaust air outflow - about 15-20 cm below the ceiling, as a rule, on the opposite to the supply wall.

Popular schemes for the device of bath ventilation

Only the options for arranging ventilation in the steam room deserve separate consideration - in the other rooms everything is performed according to the standard scheme, for example, like this:

The air exchange in the steam room can be organized according to the 4 basic schemes shown in the following image.

Scheme "a". The most popular option. The air intake window is next to the stove, at a distance of about 25-30 cm from the floor. The incoming clean air gradually displaces the warm waste up to the opposite wall. On it, about 15-25 cm below the ceiling, there is an exhaust hole.

Scheme "b". Both holes are on the same wall. The circuit will only work if an exhaust fan is installed. Fresh air enters through the bottom hole in the wall opposite to the stove. The air will rush in the direction of the stove, and then, covering the space of the steam room with an arc, move to the hood and be discharged outside the bath.

Scheme "in". The variant is suitable for steam rooms with leaking floors. The inlet is located as in the "a" scheme. After warming up in the upper part of the steam room, the air descends to the floor, passes through the gaps in the boardwalk, contributing to more efficient drying of the boards, and then it is discharged through an exhaust hole, usually set up in another room. Extraction can also be carried out through a separate insulated duct.

Scheme "g". Option for baths with a constantly working stove. In this case, the functions of the hood are performed by the blowing hole of the furnace. The inlet window is installed under the shelf, in the wall opposite to the stove. The height of the air inlet must correspond to the height of the furnace hearth. Fresh air rushes to the stove, displacing the air masses heated by it to the ceiling. Cooling down there, the air descends and is removed from the bath through the blower.

To make the operation of the air exchange system as efficient and high-quality as possible, study and remember a few simple tips before starting its installation.

If your bath has a bathroom or even a kitchen, equip them with only exhaust ventilation - this solution will exclude the possibility of spreading unpleasant odors in other rooms. Alternatively, you can equip supply ventilation in other rooms, and equip the bathrooms with a natural exhaust - in this case, the air will move to the bathrooms.

When calculating the performance of the fans, it is recommended to reduce the total power of the supply units by 5-10% of the total performance of the exhaust units. In this case, the exhaust air will be completely displaced by the incoming air masses, and a margin of 5-10% will compensate for the inflow of air entering through windows, cracks, etc., which will allow maintaining a balance.

In rooms with only natural ventilation, it is recommended to make opening vents - this will increase the efficiency of fresh air intake and reduce the risk of fungi, mold, rot, etc.

Important! If your bath has a non-typical configuration, the ventilation system project will also be individual. When compiling it, the peculiarities of the composition of the premises, their design, structural features, etc. should be taken into account.

The main stages of self-arrangement of the ventilation system

Any ventilation system in any room is set up in approximately the same sequence. Differences are present only in the characteristics of the air vents and their locations, as well as in the configuration of the system (mechanical, unlike natural ones, are supplemented by various kinds of devices).

For example, the following arrangement of ventilation elements can be used.

Or its somewhat modified analogue, presented in the following image.

Recommendations regarding the choice of the location of each hole, the type of air exchange system for different rooms of the bath, as well as the procedure for determining the characteristics of the ventilation elements, have been discussed earlier.

Along with this, the order of arrangement of ventilation may differ depending on which design option you prefer. There are few solutions available:

- independent ventilation in each room. A simpler option. The work is limited to the installation of transoms, vents, fans and other necessary elements, if provided by the project. Fans can be installed both in windows and in separate ducts leading to the street through the wall;

- centralized system. More complex option. Requires laying of ventilation ducts. It is used mainly in private houses - in the case of a bath, this option will be too costly and time-consuming;

- "Hybrid" option. Some rooms are individually ventilated, some are combined into a joint system.

A reasonable option for using in a bath is independent ventilation - the owner can choose the optimal characteristics of fans and other elements for each room, saving money, time and effort on the activities necessary to combine the channels into a single system.

Important! The location of some rooms of the bathhouse may not allow to equip an independent supply and exhaust ventilation. In this case, it will not be possible to avoid laying ventilation ducts. Alternatively, the boxes can be placed in the attic, and the ventilation holes can be arranged in the ceiling or connected to the channels equipped in the walls (the option is more complicated if the laying of such kind of channels was not provided for by the project during the construction stage of the bath).

In most cases, the first option is used: ventilation pipes of the required length are led out through openings in the ceilings of the serviced premises and either each is equipped with its own fan, if necessary (easier to implement for an unprepared user, the procedure is similar to that shown in the following table), or they are connected into a single circuit and are connected to a common hood (may require the involvement of specialists).

Remember: the maximum efficiency of the ventilation system is ensured when using the shortest and most direct air ducts - up to 3 m when arranging natural air exchange and up to 6 m when using electric fans.

The procedure for arranging an independent ventilation system is shown in the following table.

Important! In the example, instructions for arranging a mechanical ventilation system with the use of fans are considered. The procedure for installing natural air exchange remains almost the same: only the stages of laying wires and installing fans are excluded.

Table. Ventilation arrangement

| Stage of work | Explanations |

|---|---|

| The operating procedure remains the same for the inlet and outlet openings. Only the height of their arrangement and location change (possible options were considered earlier), as well as the type of fans used (supply or exhaust). The characteristics of the latter are selected individually, taking into account the volume of the serviced room, the required speed of air movement in the ducts, the required frequency of air exchange, etc. - all these points were discussed in the theoretical part. We arrange the holes in the following order: - we outline the center and contours. We make the marking so that the diameter of the hole as a result slightly (usually a 2-3 mm gap is made) exceeds the diameter of the pipe to be installed (recommendations for choosing the diameters of air ducts were given earlier); - using a punch, make a hole in accordance with the markings. We hold the working tool horizontally, but with a slight downward inclination; - carefully take out the cut material (a hammer and a chisel will help us with this), after which we thoroughly clean the finished hole from dirt and dust. |

| The ventilation pipe (ventilation duct housing) is placed in the prepared hole, but before that (if mechanical / forced ventilation is planned) it must be equipped with a fan. Useful recommendation! Initially, buy ready-made ventilation kits, including, in addition to the accompanying additions, an air duct / pipe and a fan with an appropriately sized case - this way you will avoid difficulties during the assembly phase. A pipe with a fan is placed in the prepared hole, and the remaining slots are filled with polyurethane foam. |

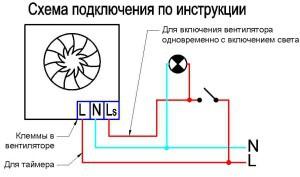

| The fan is an electrical device, therefore, it must be connected to the mains. Let's do this while the polyurethane foam dries (at least 10-12 hours). The procedure is standard: - the contours of the cable grooves are cut in the wall with a grinder. Excess material is removed with a bump stop; - a hole is prepared in the wall for installing the switch box (for example, a puncher can be used). The box is installed (first read the instructions specifically for your switch). The switch itself will be installed after finishing; - the wire is laid in the strobe. We use alabaster to fix the cable; - we connect the wire with the switch and the fan. We must first study the connection diagram recommended by the fan manufacturer in the attached instructions, because it may differ from device to device. One of the most commonly used schemes is shown as an example. |

| It remains only to bring the entire structure into its proper form. To do this, do the following: - we get rid of excess dried polyurethane foam with a knife; - we putty the grooves; - we mount adjustable ventilation grilles on both sides of the pipe. We use self-tapping screws for fastening. If provided, at the appropriate stages of work, we install additional elements (for example, an air heater, filter, etc.). Each of these devices is mounted individually - we preliminarily clarify these points in the manufacturer's instructions. |

Video - Arrangement of ventilation openings

Video - Ventilation in the bath with your own hands - diagram

A visit to the bath is not only a way to get rid of weekly dirt, but also to lose extra pounds or remove toxins and toxins from the body. However, a beneficial effect on the body can be felt only with the correct ventilation in the bath, which in most cases turns out to be far from ideal.

It would seem that in order to preserve heat and increase the speed of warming up the room, it is necessary to close up all the cracks, and lay a seal around the perimeter of the doorway so that the door closes tightly and does not serve as a source of cold air inflow. However, everything is exactly the opposite, since well-planned ventilation contributes to:

- creating a comfortable microclimate by getting rid of excess heat, humidity levels, as well as reducing the concentration of carbon dioxide;

- rapid heating of the room due to the mixing of air masses, which is also accompanied by minimal fuel consumption;

- protection of interior decoration, as well as the floor of the building from the appearance of various kinds of mold, fungi that contribute to the appearance of an unpleasant odor;

- high-quality ventilation of all rooms of the bath, extending the service life.

Thus, ventilation in the bath plays a very important role both for the preservation of the bath structure over a long operating period and for health benefits. At the same time, it will not be difficult to choose the required type of ventilation system, since you will have to choose only from 2 typical systems.

Types of ventilation systems, their characteristics

Before you learn how to make ventilation in a bath, you need to familiarize yourself with the main types and types of ventilation systems.

Based on the method of air inflow / outflow, there are 2 types of ventilation systems, each of which has undeniable advantages and disadvantages.

Natural ventilation

Air exchange with a natural ventilation system occurs under the influence of natural factors without the use of additional equipment in the form of fans, electric motors.

Among the natural factors are of no small importance:

- Wind pressure. The inflow of fresh air into the bath is carried out under the influence of the wind force through cracks in the walls, in the openings of doors, or windows from the windward side. In this case, the flow of air is accompanied by the simultaneous displacement of discharged air masses through the existing slots, which accumulate inside the bath at the top of the opposite wall.

An increase in the wind pressure leads to an increase in the mass of discharged air, thereby improving the ventilation of the sauna room.

- Aeration. Cold air entering the heated bath through slots at a low height from the floor or specially arranged openings gradually displaces hot air masses downward, contributing to uniform heating of the room due to mixing of air layers and the outflow of contaminated air from the bath.

The advantages due to natural ventilation in the bath boil down to the following:

- safety associated with the lack of devices operating from the network;

- simplicity, since small gaps in the doorway or on the wall are an integral part of a wooden bath;

- low cost, since there is no need to purchase additional materials, as well as to pay the costs for the operation of such a system.

Among the disadvantages, it is worth highlighting:

- the efficiency of ventilation is entirely dependent on external natural factors;

- inability to adjust the degree of ventilation.

Thus, natural ventilation in a wooden bathhouse for one family is quite enough, since the tree itself is a breathing material, and cracks in the wooden structure in the process of shrinkage still occur. At the same time, for full ventilation in a brick bath, it is better to stop at an artificial system, since the formation of gaps when using such a building material is quite a rarity.

Mechanical ventilation

Air exchange in the bath takes place regardless of the influence of external factors of nature using various kinds of fans, pumps and other equipment that contribute to the renewal and faster heating of the air.

The advantages of artificial ventilation:

- maintaining the microclimate in the bath at a given level;

- the possibility of filtering the incoming air;

- adjustment of the uniform distribution of heated air masses inside the room.

Disadvantages:

- higher cost relative to natural ventilation;

- labor intensity of installation;

- noise during operation;

- costs for the energy consumed by the devices.

The forced ventilation system in the bath, based on its inherent task, implies the use of such types of ventilation as:

1. Supply room - provides access to the room with the required volume of clean air. A typical mechanical ventilation system includes an air duct, an air intake grille, a filter and an air valve. However, the greatest effect from the construction of supply ventilation in the bath is achieved through the installation of an electrically driven fan.

2. Exhaust - promotes the removal of exhaust air from the bath room by means of a system consisting of an air duct, a grate, an electric motor, and a fan.

3. Supply and exhaust - combination of functions of supply and exhaust systems. In this case, the distribution of air masses inside the bath occurs by:

- displacement of hot air outside the premises as a result of a gradual rise of air masses newly supplied through the supply ventilation;

- mixing hot and cold air due to the constant flow of fresh air.

Regardless of the type of ventilation, the cross-section of the ventilation opening must be 24 cm by 1 m³.

Thus, forced ventilation is several times higher than the natural ventilation system. Based on this, an artificial ventilation system is the most optimal solution for arranging ventilation of a frame bath. At the same time, do not forget that the supply and exhaust openings have a strictly ordered arrangement relative to each other, and not chaotic.

Ventilation hole placement options

The intensity of air exchange inside the bathhouse largely depends on the correct distribution of the ventilation openings in relation to one another. Despite the variety of options for the alternative arrangement of openings for air inlet / outlet, the following ventilation schemes for the bath have gained the greatest popularity:

- The air flow is carried out behind the heater through an opening located at a distance of 30-40 cm from the floor level. In this case, the exhaust hole has the same height, but is located on the wall opposite to the air flow and is equipped with a fan. The cold air entering the room hits the wall of the heater and rushes upward, gradually warming up during the ascent. At the same time, the exhaust air begins to move downward and, under the action of the fan, is discharged outside. This mixing of air masses leads to uniform heating of the air.

- The principle of air movement in the bath is similar to the first option with the only difference that the height of the inlet opening is taken about 50 cm from the floor surface, and the exhaust outlet is located at a distance of 10-20 cm from the floor line. In this way, an even more intensive air exchange is achieved.

- The inlet is created at a distance of 30 cm from the finished floor in the wall opposite the stove. In this case, the functions of the exhaust are performed by the chimney, along with the blower of the furnace. However, such a scheme is valid only during the operation of the furnace.

- The distance from the floor to the air inlet located in the wall opposite the stove is 20-30 cm. In this case, the hood equipped with a fan is located on the same wall at a distance of 20-30 cm from the ceiling. The air that has entered the room hits an obstacle in the form of a stove and begins to rise upward, heating up and displacing the polluted air as it rises.

- The air inflow occurs at a distance of 20 cm from the floor in the wall behind the stove. The newly received air masses rise, gradually warming up, to the ceiling. As it cools, the air descends and leaves through the genital crevices, after which it enters the ventilation pipe, and from there outside the structure.

Thus, the exhaust outlet can be located below the inlet only if there is a fan.

Several excellent ventilation schemes in the bath, the video of which is presented below, will help you make the final decision about your own design.

Bath ventilation device

Every year the construction of the bath becomes more complicated, creating more comfortable conditions for those who like to take a steam bath or just wash in the bathhouse. If earlier the bathhouse included a dressing room and a washing room combined with a steam room, today the bathhouse consists of 3-4 rooms:

- dressing room;

- washing;

- steam room;

- restroom.

Of course, the most important of these are the steam room and the washing room. However, the ventilation system must be arranged not only in these rooms, but also in the dressing room, as well as in the rest room, since the humidity also spreads to the rooms adjacent to the steam room.

Steam room

For ventilation of the steam room, any of the above schemes is suitable. However, before heating the stove, it is necessary to completely ventilate the steam room by opening the door and all ventilation openings for 5-10 minutes. After the ventilation is completed, the door as well as the exhaust vents are closed. When the temperature in the steam room reaches the required limit, you can slowly open the exhaust hole, adjusting the intensity of air exchange by means of a valve. In this case, the diameter of the exhaust hole cannot be less than the supply hole, otherwise back draft will occur, as a result of which the air flow will be reduced. However, it is necessary to ensure that the flow of air does not violate the temperature regime inside the steam room.

Washing room

Along with the steam room, the washing room of the bath is also associated with a large amount of moisture, the timeliness of getting rid of which is very important, since mold and dampness have a detrimental effect on both the human body and the duration of the structure's operation. Due to the fact that a large amount of water accumulates under the floor, an asbestos pipe located in the corner of the sink can be used for ventilation in the washing bath. In this case, one end of the pipe must be between the finishing and subfloor, and the other is brought out to the roof and equipped with a deflector.

If the oven is in a washing room, then the oven blower located below the finished floor will also play the role of a good hood.

Foundation

When planning a building, you must immediately think about ventilation of the bath foundation, since the laying of ventilation holes occurs at the stage of concrete reinforcement. To create ventilation holes, asbestos pipes are quite suitable, which are strictly horizontally fixed in the designated places by means of wire and reinforcement rods, after which the pipes are covered with dry sand. At the same time, the distance from the ground level to the pipe should be at least 10-15 cm, so that when groundwater rises during the off-season, you do not worry about the possibility of flooding. After fixing the pipes, the foundation is poured with concrete. In this case, the sand is removed only after the concrete has completely hardened. For normal ventilation of the foundation, 2-4 holes with a diameter of 10 cm are sufficient, located in opposite places. To protect against insects, the openings are protected by installing grilles with mesh on the ventilation openings.

Dressing room

An integral part of any bath is a dressing room, where a mini-changing room is arranged. In addition, a stove is often placed in the dressing room. In most cases, this is due to the small area of the steam room or in order to prevent the accumulation of debris directly in the steam room. At the same time, the stove perfectly copes with the ventilation functions in the bathhouse dressing room, because it is necessary to get rid of the condensate that appears as a result of opening the steam room door.

If there is no stove in the dressing room, then after the bath procedures, you can simply open a window or door to the street and thoroughly ventilate the room.

An alternative ventilation option is to install an exhaust vent equipped with a fan at the top of the wall adjacent to the street.

Based on the specific situation, one of several options for ventilation of the room is used. However, it is necessary to think over all the little things in the arrangement of the dressing room during the planning period.

Thus, it is not so difficult to build ventilation in the bath with your own hands. The main thing is to carefully approach the planning process and choose the right type of ventilation system, which largely depends on the structural features of the structure and the location of the bath.

The Russian bath is very healthy. The fundamental point in its construction is a well-equipped ventilation in the sauna in the steam room. This room is usually very hot and humid. Correctly organized air circulation is a prerequisite.

Often, many homeowners have doubts about whether they need ventilation in the steam room. The proposed material will allow you to correctly answer this question and solve all problems with the arrangement of ventilation without much difficulty and without significant material costs.

Ventilation in the steam room requires air circulation

What is ventilation in the steam room for?

Correct ventilation of the steam room of the bath helps to solve the following tasks:

- maintaining a comfortable indoor temperature;

- health safety;

- the safety of the wood used for the interior decoration of the steam room.

Ventilation vents in the steam room help to regulate the temperature, and keep the wood from dampness and fungus longer

Ventilation vents in the steam room help to regulate the temperature, and keep the wood from dampness and fungus longer If the ventilation of the steam room in the Russian bath is not equipped correctly, the appearance of such negative factors as:

- rapid cooling of heated air;

- accumulation of gases during the adoption of procedures;

- premature decay of finishing materials;

- the appearance of harmful microbes, bacteria, mold, fungi;

- unpleasant smell.

The proposed material will describe in detail what should be properly organized ventilation in the steam room of a bath, video and photo materials will clearly illustrate all the key points.

Basic principles of steam room ventilation

The specific layout of the ventilation arrangement is usually selected taking into account the architectural features of the structure itself, the size, number of rooms, etc. In this case, it is necessary to strictly observe the basic principles of arranging ventilation systems for steam rooms in Russian baths. If they are violated, various negative phenomena may arise that pose a serious threat to the health and life of vacationers.

The fresh air inlet is located just above the floor level. In order for the incoming air to immediately warm up, the input is located in the immediate vicinity of the furnace.

The exhaust air outlet is located under the ceiling. The main thing is that the air inlet and outlet are arranged on opposite walls.

Important! Under no circumstances should the indicated holes be placed on the same level! The air in the interior space will not fully circulate. Temperature differences will occur, posing a serious health hazard.

The dimensions of the inlet and outlet must be identical. They are selected depending on the dimensions of the internal space of the steam room. For 1 cubic meter m of air you need 24 cm of pipe diameter. If necessary, the arrangement of additional air outlets is allowed.

The ventilation of the steam room is arranged in such a way that the exhaust air is completely replaced every 3-4 hours. This is required by the standards of sanitary and fire safety.

The ventilation opening in the bath is equipped with valves to regulate the air flow

The ventilation opening in the bath is equipped with valves to regulate the air flow The ventilation device in the steam room of a bath requires the mandatory placement of a valve system. You can use special blinds for this. This will allow you to adjust the amount of air inlet and outlet. If necessary, the bath can be heated or cooled very quickly and without much difficulty.

You need to think about how to make ventilation in the steam room of a bath already when drawing up a project. This will allow all ventilation pipes, openings, etc., to be correctly positioned during construction. This will allow you to properly equip mines, lay pipes and perform all other work. It will be much more difficult to equip the air circulation system after the completion of construction work.

Before building a bath, it is necessary to consider the location of the ventilation ducts in the bath

Before building a bath, it is necessary to consider the location of the ventilation ducts in the bath Varieties of ventilation systems for the steam room

Ventilation in the steam room (see photo) is of 3 types - natural, forced (i.e. mechanical) and combined. The choice of a specific system is made taking into account such factors as:

- the size of the steam room and the overall dimensions of the building;

- it is possible to correctly place the exhaust pipes;

- the material from which the bathhouse was built;

- using the bath all year round or only during the summer season.

Warm air is lighter than cold air. Therefore, with properly equipped ventilation in the steam room, the heated streams rise to the ceiling and are gradually drawn out through the ventilation hole. The air coming from the outside is immediately heated from the stove and passes into the room without creating a temperature difference. This is the basic principle by which ventilation in a steam room works.

Natural ventilation

The natural ventilation system ensures air exchange due to different levels of pressure and temperature in the interior (in the steam room) and outside, i.e. outside. When the exhaust air exits through the outlet, the internal atmosphere in the room is discharged, creating conditions for drawing in cold air through the bottom inlet. In this case, special attention should be paid to the insulation of the bath. Otherwise, high-quality heating will not work.

Natural ventilation in a steam room in a frame bath is most often used for small buildings, erected from breathable material, that is, from wood. In this case, small gaps in the log walls become additional elements of the ventilation system. The main advantage of natural ventilation is its low cost.

Forced and combined ventilation

A mechanical or forced ventilation system in a steam room is sometimes necessary if:

- the total area of the bath is large;

- the structure was erected from bricks, cinder blocks, stone;

- the pair office is very large;

- exhaust pipes cannot be placed correctly;

- reinforced power oven.

Do-it-yourself forced ventilation of the steam room is mounted without any problems. In this case, the following are used:

- fans;

- supply valves;

- deflectors.

Forced ventilation in the bath is suitable for large rooms

Forced ventilation in the bath is suitable for large rooms Nuance! The ventilation system in the steam room in the steam room, heated with a gas water heater, requires the arrangement of a separate ventilation duct.

The combined ventilation system is equipped with the elements of both of the above systems. Fresh air enters in a natural way, i.e. through the bottom inlet. Exhausting the spent air masses is provided by mechanical devices.

How to choose a fan for a steam room

A classic duct-type fan is not suitable for a steam room. High temperature and humidity are detrimental to such devices. In the steam room, special fans are used. The material for their manufacture is glass-filled polyamide. Such models are resistant to moisture and can withstand temperatures up to 130 ° C.

Glass-filled polyamide - ideal material for steam room fans

Glass-filled polyamide - ideal material for steam room fans The fan model is selected in accordance with the technical specifications.

Remember! Ordinary room fans can only be used for final drying and ventilation of the steam room after taking procedures and subsequent cleaning.

If you have money, you can install a self-regulating system for ventilation in the steam room. This device will automatically provide air inflow and outflow, temperature, humidity level. It is advisable to purchase such systems only from trusted manufacturers.

Basic schemes

What ventilation can be in the steam room of a bath, the diagram, video and other materials attached below will clearly show. You just need to choose 1 of the 4 attached options and correctly perform all the necessary work.

According to diagram A, the fresh air inlet is located at the bottom behind the stove. The outlet duct is mounted on the directly opposite wall under the ceiling.

The chimney is installed vertically. Its length is calculated so that the upper edge of the pipe rises slightly above the roof ridge. This will ensure the normal functioning of the ventilation system during strong winds.

Scheme A of the location of ventilation in the bath

Scheme A of the location of ventilation in the bath Correctly sized air exhaust pipes will ensure the natural circulation of air masses. Additional adjustment is provided by installing dampers.

The use of scheme B is assumed only if only 1 of the walls of the steam room can be used for arranging ventilation. Air openings are located opposite the heater. The inlet is raised 30 cm from the finished floor. The outlet window is lowered 20 cm from the ceiling.

Diagram B Location of ventilation ducts opposite the heater

Diagram B Location of ventilation ducts opposite the heater The air passing through the bottom entry heats up from the oven and rises towards the air outlet. Mechanical pulling devices are required for the system to function properly.

According to scheme C, it is possible to provide ventilation not only for the steam room, but also for the underground space. The inlet is located in the wall behind the heater. It must be raised 20 cm above the finished floor.

Scheme C with air flow under the bath floor

Scheme C with air flow under the bath floor The heated supply air flows into the plinth through the slots of the leaking floor. Then it returns to the steam room and moves in the direction of the exhaust outlet. From here, the spent air masses go out.

For a constantly used bath, ventilation can be applied according to scheme D. In this case, the inlet is equipped at the bottom, but opposite the stove, and not behind it, as in other options. Height above the floor - 20 cm. Exhaust air extraction is provided by means of a blower and chimney.

In order for the ventilation in the steam room to work effectively, it is necessary to choose the right location for the heater. It is most convenient to equip it precisely inside the pair department. If the stove is located in an adjacent room, the efficiency of the ventilation system and the heater itself will be noticeably lower.

Preparatory work

To arrange ventilation in the steam room, you must prepare the following materials:

- brick and / or stone;

- cement and sand;

- ventilation ducts;

- ready-made valves or material for their manufacture;

- a metal sheet;

- lining for box sheathing;

- fastening material - nails, screws, screws.

To work, you need the following tools:

- saw-hacksaw;

- Bulgarian;

- hammer;

- screwdriver;

- tape measure, level, plumb line;

- construction mixer;

- drill or hammer drill;

- a set of spatulas;

- container for mixing the solution;

- technical knife;

It is better to carry out work in special clothing. Wear gloves and a respirator if necessary.

Installation of supply ventilation

An inlet channel for supplying fresh air is located in the immediate vicinity of the furnace of the sauna stove. It is desirable that the inlet is located above a sheet of metal sheathing to protect the wood from accidental ingress of small coals.

First, you need to make a box from a suitable material. Its dimensions should exceed the dimensions of the chimney by about 20%. The outer opening of the box is located on the outer wall. It is undesirable to place it in the base.

If the firebox is located in the steam room itself, the convection box is additionally equipped. At the wall in which the air inlet is located, a podium should be laid out of bricks placed on the edge. They are laid out in 3 rows - under the wall, in the middle and on the edge.

The masonry for the stove is arranged at a height of 25 cm. It must be brought to the brick screen and must be covered. In order for the newly supplied air to pass directly into the furnace, it is better not to lay the last 2 bricks. The end is lined with bricks.

The convection box is fully assembled. A blower is equipped at the end. A protective substrate is made under it to preserve the floor covering.

When the podium is completely ready, you can start installing the oven. For even distribution of the load, it is advisable to use a metal corner.

After the final installation, stone or brickwork is arranged around the stove. To form a gap, it is moved 5-6 cm away from the oven. Next, a special screen is installed. Holes must be formed in it for the passage of hot air.

Exhaust ventilation installation

The outlet duct is installed diametrically opposite from the inlet. It is raised above the finished floor by 30 cm. The inner area of the box is approximately 1.25 m².

Through the wall, the outflow box is led to the ceiling and an external outlet is equipped for it. Exhaust air can be discharged to an adjacent room. In this way, it will be possible to warm it up at no extra cost.

Exhaust ventilation can be placed on top of the ceiling

Exhaust ventilation can be placed on top of the ceiling To avoid accidental burns, the chimney box must be covered with a brick or stone casing. At the same time, a special hole with a door must be left below, which will be a blower. An additional opening, equipped on top, will allow the chimney to be used as a heat pump, this will create both heating of the room and proper air circulation.

How to ventilate a Russian bath

The correct ventilation device in the steam room of a Russian bath does not imply the use of any mechanical devices. Otherwise, the heated air will be very quickly discharged outside. The efficiency and pleasure of bathing procedures will be significantly reduced.

In the Russian bath, natural ventilation is used, where air outflow is carried out through the window

In the Russian bath, natural ventilation is used, where air outflow is carried out through the window Therefore, the Russian bath must be carefully cleaned, ventilated and dried after each use. For ventilation, a special window is installed in the wall opposite the door. A mechanical hood can be used. The door must be kept open when ventilating.

It is necessary to remove leaves from brooms and random objects from the beds. Then you need to wash all surfaces and dry them with towels and / or a special absorbent cloth. This will protect against mold growth and the growth of harmful microorganisms. After cleaning, airing and drying, the steam room is ready for further use.

The steam room in the Russian bath is combined with the washing room, so it must be dried after each use.

The steam room in the Russian bath is combined with the washing room, so it must be dried after each use. How to warm up a Russian bath

First you need to melt the stove. In this case, the outlet holes must be kept closed. Only input is opened.

After warming up the room to the desired temperature, you need to open the valve of the lower air outlet pipe. This will ensure proper air circulation. The temperature will not drop.

In order to warm up the stove, it is necessary to open the valve in the stove of the Russian bath

In order to warm up the stove, it is necessary to open the valve in the stove of the Russian bath Passing into the box from below, the heated air will gradually displace cool air masses to the outlet. When passing through the box, they will provide additional heating of the room. Steam room ventilation will also take place in parallel.

If the ventilation is not working properly

When using the steam room, it is necessary to periodically check the health of the ventilation system. With good air circulation in the steam room, it is always easy to breathe, the body heats up evenly, the temperature and humidity are maintained at the required level.

If the ventilation in the steam room was installed incorrectly or became unusable over time, symptoms such as:

- copious condensation on vertical surfaces;

- mold, especially in the corners;

- foul smell;

- uneven air heating;

- drafts;

- slow setting of the required temperature;

- excessive heat loss;

- unpleasant internal atmosphere that makes breathing difficult.

Mold in the steam room indicates a lack of ventilation

Mold in the steam room indicates a lack of ventilation If at least 1 or 2 of the above factors are present, then the ventilation in the bath in the steam room is not equipped correctly. Another option is clogging and / or damage to the system, the need for urgent repair and / or thorough cleaning of individual elements or the ventilation system as a whole.

Clogged ventilation ducts interfere with its operation

Clogged ventilation ducts interfere with its operation From all of the above, it becomes clear that it is inexpensive and not very difficult to properly ventilate the steam room. However, this requires careful adherence to all technologies. The attached video "How to make ventilation in the steam room of a bath" will help to avoid mistakes.

There is already a large review material on our website, so now it is worth talking separately about the cooker hood in the bath: how it works, how it works and how to make it yourself.

Hood in the bath: depending on which bath

Baths are built from a variety of materials, each of which has its own specifics. This also affects ventilation systems, which have their own characteristics in each case. We will talk about their differences in terms of organization below.

Sauna extractor hood

A sauna or a Finnish bath differs from a Russian one in a small amount of steam (this is practically a dry bath) and a high temperature (which can reach 130 degrees!). During your stay in the sauna, there is a clear rule regarding ventilation: the air must be changed at least 6-8 times per hour. This requires good air flow control, replacing the exhaust air with fresh air less than every 10 minutes.

Ideal for a sauna, (convection type). Let us briefly repeat that it operates according to the principle of an "inverted glass":

- ventilation duct standing diagonally from the stove, takes in near-field air;

- takes him out through the roof (wall);

- below, next to the stove, there is an inlet through which fresh air comes in;

- the stove heats up the oxygen-rich air, it rises and spreads through the sauna.

Flow regulation is carried out using dampers that regulate the openness of the duct and inlet. An important point in this case is the constant operation of the furnace, because it is she who performs the function of a "pump".

And even if the hood in the sauna is done according to a different scheme, the task will remain the same:

- driven frequent air exchange;

- good warming up arriving fresh air;

- inadmissibility fast air currents (more than 0.3 m / s), i.e. drafts.

In the bathhouse from the log house

The log house was invented long before the laws of physics, on which natural ventilation is based, took shape. Nevertheless, the builders of log baths actively used these laws so that the owners of the bath did not suffocate while steaming, and the bath stood for decades. (Of course, the hood in the bathhouse from the log house will not save it from fire, but from rot - it may well.) In the frame, the air flow was ensured by the lower rims, which were deliberately laid loosely, that is, they had slots through which fresh air was "pulled". In addition, the door to the steam room below did not fit snugly to the floor.

Depending on how exactly the bathhouse was heated from the log house - "in black" or "white" - it also depended on where the exhaust air went.

- In a heated "black" bathhouse, the stove does not work during the steaming process, so an open window or door was used for the outflow.

- In a heated "white" bath, the outflow was made through the chimney. The stove was working at the same time.

In principle, nothing prevents the organization of ventilation of the log house in the traditional way today. But the decision must be made promptly, even at the construction stage. Because a more modern solution should be incorporated into the project. Alternatively, you can punch holes (supply and exhaust) directly to the street and provide them with plugs or dampers. One is next to the oven blower, the second is above the upper shelf on the adjacent or opposite side. Or make two exhaust holes, one above and one below the top shelf. Another option is to make blinds at the bottom of the steam room door, and an exhaust hole under the ceiling of the shower room.

IMPORTANT! If you don't want to go outside, you can lay air ducts, but then instead of natural you will have to install a forced ventilation system.

In a foam block bath

A foam block bath is no exception to the rule that you need to think about ventilation when designing a bath. It's easier than punching ready-made walls. In order to provide a cellular concrete bath with sufficient air circulation, which will relieve the structure of excess moisture, it is necessary to lay pipe cuttings at the time of pouring the foundation formwork, which will then become airflows.

For a bathhouse, which is not in the lowlands and is not surrounded on all sides by buildings, two ducts on opposite sides are enough, otherwise they are made 4. Do not forget about the ventilation gaps between the walls and the insulation.

The roof must also be ventilated, receiving inflow from the roof overhangs and giving air through the raised ridge. In the premises, supply and exhaust openings are made according to one of the standard schemes.

In case of insufficient natural ventilation, it is recommended to install fans on the hood from the foam block bath.

Sauna hood: in which compartment?

If we leave aside the questions about ventilation of walls, foundations and roofs already discussed in other articles, there are rooms - a steam room, a washing room, a dressing room and a rest room - where you need to organize air circulation. At the same time, there are certain standards regarding ventilation in each of them and the specifics of manufacturing the hood. But first things first.

Steam room hood

For those who are soaring, the hood in the steam room of the bath is a guarantee that they will come out of there safe and sound.

IMPORTANT! You cannot leave the steam room without ventilation openings at all, this is a big risk of getting dark or losing consciousness and suffocating with carbon dioxide. You cannot make only one hole.- this is how ventilation does not work.

The way to ventilate the steam room can be natural (due to the laws of physics) or forced (due to fans). The holes can lead outside, into air ducts and into adjacent rooms. Either blinds or dampers are installed on the ventilation openings. The air supply can be organized through the bottom of the steam room door, which is 3 cm from the floor, or with louvers at the bottom of the door leaf.

You only have to make a box with your own hands. Everything else (corrugation, valves, gate valves, dampers) is on sale. Fans (if needed) vary in diameter and power. A relay can be used to automatically control forced ventilation. The holes in the wall were either left behind during construction, or are punched through in an already built bathhouse.

Useful video

See how the craftsmen made a box for ventilation hoods from the boards:

In the washing room

According to the already mentioned standards, the air circulation in the washing room per hour should be a multiple of 8 volumes of the room for supply ventilation and 9 for exhaust. It means:

- that the dimensions of the exhaust hole will be more supply;

- or the fume hoods will be two for one supply;

- or delivered to the hood fan.

In any case, this is an intensive air exchange, which is primarily intended for quick drying of the washing room. It is not required during the washing process, therefore it is regulated by flaps.

By the way, inlets can be made in a dressing room or a rest room, and exhaust outlets in a washing room. This will allow you to ventilate two rooms at once. Similarly, the hood is done in the bathroom, moreover, it is forced to create low pressure. Then the air will be drawn from adjacent rooms and leave through the forced exhaust. Thus, the rooms are connected with through holes, which on the one hand will be supply air, and on the other - extract air.

The components of the hood in the washing bath do not differ from those used in the steam room.

How to make a hood in a bath

This has been said more than once, and yet it is worth repeating: the cost of arranging ventilation will grow many times over if done late, after the completion of construction. At the same time, the principle of creating ventilation in the bath remains unchanged: it is necessary to create conditions for the inflow and outflow of air from the premises. So, how to make a cooker hood in a bath with your own hands or with the hands of professionals.

Hood in the bath: scheme

There are many schemes, but one is suitable for understanding the principle of ventilation. Most often, ventilation schemes for the steam room are offered, but the scheme for the entire bath, with explanations, is of much greater interest.

Take a look at the sketch. It shows that ventilation is carried out in the washing room, steam room and rest room. Moreover, the flow of air is carried out from one pipe to two points, one of which is in the steam room, and the second in the rest room. The hood is located in the washing room, in the steam room, and in the relaxation room. We will describe all ventilation devices in each room:

- Washing room- a window made of metal-plastic, an adjustable hood that draws in air through a diffuser located on the ceiling. From there, the air goes through a pipe to the roof.

- Steam room- insulated window, located below the shelf, adjustable hood, which is a vertical box, the intake hole of which is 150 cm² below the shelf, and the exit from the chimney to the street is near the ceiling. One of the regulated inflow channels near the stove, cross-sectional area 150 cm².

- Restroom- adjustable hood, which is a box with a cross-section of 150 cm², the height of the intake opening is 30-40 cm from the floor, exit through a pipe to the street near the ceiling. Regulated inflow through the second channel with an outlet near the stove firebox.

With your own hands: how to do it right

Do-it-yourself hood in a bath is not something that cannot be done, but you need to approach the matter prudently and slowly. In order to make the hood yourself, you need to prepare the materials according to it. It is also necessary to calculate the cross-section of the ventilation pipes.

IMPORTANT! The inflow volume must be equal to or less than the exhaust volume.

To do this, you need to know the volume of the room and the multiplicity factor (how many times the air must be updated per hour) - it is in the standards. In the main air ducts, the speed of movement should not exceed 5 m / s, in the branches - 3 m / s, in the steam room - 2 m / s, natural ventilation - up to 1 m / s. Further, in the table, we find the value of the pipe cross-section, which is the closest to give the required volume at a given speed.

Knowing the cross-section, it remains to prepare a corrugation or pipes of the corresponding diameter, which are attached with one end in the room at the required height according to the diagram, and with the other they go outside. Self-tapping screws, metal tape and foam are used for fastening. The openings are supplied with dampers in the room, grilles at the outlet. By the way, ventilation should be cleaned once a year..

Useful video

Watch a small video, which clearly shows ventilation in one bath:

+++

Well, now you know exactly how to properly make a hood in the bath in order to save yourself, household members and guests from suffocation in the bath. It remains only to correctly apply the information received.

In contact with