Having a country house or summer cottage, one of the main points of arrangement is the installation of a reliable and durable fence, which will become protection from intruders, prying eyes of strangers.

A brick fence will perfectly cope with this function. You can independently build it around the entire perimeter of the site or invite a team of craftsmen to help.

Read about other country buildings:

Since the material will be used exclusively for outdoor work, it is necessary to make the right choice in favor of a brick that is resistant to external influences. Let's take a closer look at the suitable types, their advantages and disadvantages.

Red

Consists of ordinary clay. It is fired at temperatures up to 800 0 C. Depending on the purpose, it can be a private and a front one. By filling - hollow or corpulent.

Benefits:

- high strength;

- frost resistance;

- dense.

There are no significant drawbacks.

Clinker

The production technology is similar to red, but the firing temperature is several times higher. Due to this, the clay is better sintered, acquiring greater strength.

Among the pluses:

- resistance to high humidity;

- does not lose its properties with sudden temperature changes;

- durable.

The main disadvantage is the high price.

Silicate (white, yellow)

It will be the cheapest in terms of costs. It is made by autoclaving from a mixture of sand and lime. Facial is available in three types:

- single;

- one and a half;

- double.

The latter is only hollow, the first 2 are hollow, full-bodied.

Silicate of non-standard shape with rounded corners, curved lines, and a relief surface is popular.

In addition to the usual white color, it can be painted in other colors. But it is important to remember that the mixture must contain alkali-resistant, mineral-based pigments. Any others will lead to spoilage of raw materials.

A yellow brick fence looks good if you make the decor in contrasting tones of the material.

It is worth highlighting the variety of torn or chipped stone, when there are many chips and cracks on an uneven surface.

The advantages are availability and low price. The cheapest in this category are white, gray silicate.

Disadvantages:

- low moisture resistance;

- subject to temperature changes;

- in terms of strength, it is several times inferior to other types.

Facing

This name was received due to the fact that it is used for finishing the outer parts of buildings, basements, walls, fences. The range of shapes is great. Brick imitating other materials is in demand.

The most popular colors are yellow and its combination with brown. They are chosen for cladding facades, building fences.

Aside from the standard benefits, this type of brick does not need to be plastered or painted. The material is initially completely aesthetic and ready for use.

Except for the high cost, no significant flaws were found.

Hyperpressed

Such raw materials for masonry are obtained from lime and cement. It has a high density. It will be used to build an expensive, but original and reliable fence.

Color spectrum:

- the black;

- green;

- mocha;

- chocolate;

- gray.

If you have to chop a brick, then the texture of natural stone will be visible on its cut.

The advantages and disadvantages of this material are identical to the previous form.

Thematic material:

Types of barriers

The design of such structures involves the use of one raw material or to combine 2-3 different ones.

Let's consider the features of each of them.

Monolithic

Owners of private houses often prefer a torn brick fence with the addition of forging elements. Especially when it fits into the design of the buildings. The pillars, the basement are erected from material in dark colors, while the walls are lighter or brighter to give contrast. The foundation is a monolithic tape.

One-piece brick construction serves for years, protecting the backyard area from strong wind, bad weather, and unauthorized persons. This is a good option for aesthetics. But its construction takes a lot of time, labor, money. If you want to shorten the time for creating a fence project, then you should order the services of craftsmen. They will be able to calculate the required amount of material, draw up a cost estimate and, after receiving consent to start construction, start work.

Combined

If the selected combination weighs little, then a columnar base is sufficient. For fences with columns, a brick plinth, it is recommended to give preference to a monolithic tape.

To strengthen the structure, the supports can be reinforced with shaped pipes. Jumpers are made of them.

It is better to lay out the pillars from facing bricks. Caps made of steel, fiberglass, concrete are put on top. The walls are used:

In combined versions, it is easier to equip a gate and a wicket. Especially when it comes to sheet material (corrugated board, steel).

Forging at the top of the fence looks exquisite. There are options for a white brick fence with natural stone inserts or welded parts.

Regardless of the combination chosen, it is important that the hedge is a harmonious addition to the landscape design of the whole site.

It all depends on what functions are assigned to the design.

If you want to lay out the fence solely for the purpose of decorating the territory, then half a brick is enough thickness. That is, the material is placed with its long side along the perimeter.

When a fence needs to be built to protect the site from the street and separate from neighbors, the thickness of the material should be 1-2 bricks. In this case, the long side of the raw material is placed across the fence.

To calculate the required volume of bricks, you will need to know the total area, height, and thickness of the fence.

So, for 1 m 2 of a fence, laying in 1 brick will need about 100 pcs., For laying in 2 bricks - 200 pcs.

The height ranges from 0.5 m to 3.5 m. When calculating it, you should take into account the requirements of the current legislation.

Users often search:

We analyze masonry options

When choosing any type, you should always consider 3 principles:

- Brick rows should be located strictly parallel to each other. In this case, the raw material will be subjected to minimal flexural pressure and maximally compressed.

- In each row, the sides form precise longitudinal, transverse seams.

- As a result of compliance with the first two principles, a common seam is formed.

Let's get acquainted with various masonry in more detail

Bavarian

This technique appeared in Germany and then became popular in other countries. The front parts of old German houses are laid out in this way.

Bavarian dressing involves mixing bricks of different colors without observing any pattern.

Flemish

It is used to form walls into one brick.

Feature - butt, spoon elements are stacked in one row. And in order to form small protrusions in the corners, for this, in the intermediate rows, the material should be beaten in two halves and use only one of them.

The pattern of the Flemish garden dressing differs from the usual one in that in a row after two spoonfuls, one bonded brick follows.

English

The photo below shows an example of such masonry:

When arranging a suburban, suburban area, this type of masonry is in greatest demand, since it is considered the most reliable. Applied when constructing retaining walls in a building.

It consists in alternating rows of butt and spoon bricks. In this way, no vertical seam is formed on the structure.

When forming a butt row in the corners, chipped elements are used, due to which protrusions are formed.

In the version with a garden dressing, there is one bonder behind three rows of a spoon.

Lozhkovaya

It is considered the most simple. Used for finishing works.

Spoon ligation or half-brick is that the elements in a row are shifted by 1/2 or ¼ of the length.

Step-by-step instructions for creating a brick fence with your own hands

Craftsmen are advised to build a fence from posts and piers, rather than solid masonry. Thus, the structure will last longer.

Supports should be erected in increments of 2.5 to 6 meters. The exact figure depends on the thickness and height of the product.

In the places where gates are installed, wickets are built additional pillars of brick.

Start of work - preparation of a visual drawing. With its help, calculate the exact amount of material, the masonry sequence will become much easier.

From the tools you need to prepare:

- shovel;

- master OK;

- sledgehammer;

- pickaxe;

- container for mixing the solution (bucket) or concrete mixer (for large volumes);

- level;

- roulette;

- welding machine with a mask (when reinforcing the base).

From materials:

- concrete;

- sand;

- rubble stone or crushed stone;

- brick;

- reinforcement rods.

We carry out the markup

You need to start by determining the place where the gate will be installed. Pegs are driven in along the perimeter of the future foundation at a distance of 1 m from each other. The rope is being pulled. It is important to keep the corners straight. You can use a construction square to check.

The width is 50–70 mm more masonry. As for the depth, it is better to adhere to an indicator of at least 1 m. The structure will weigh a lot, so it is important to ensure its stability. We level the bottom, walls of the trench, tamp it.

Foundation

A brick fence is a massive structure, therefore experts recommend pouring a monolithic tape under it to a depth of 50 cm.

The shape and section of the base are made the same along the entire perimeter. Here you can choose between a rectangular or trapezoidal tape.

The first type should be used for construction on stable soils with high bearing capacity.

The trapezoidal tape has a wide sole and sloped walls. To fill it, you will need rubble concrete. Reduces structural pressure on soft, moving soils.

In the variant with our step-by-step instructions, consider filling a tape with a rectangular section.

Sequence of work:

- We lay a drainage layer at the bottom of the trench - a 10 cm pillow of sand and fine gravel (gravel). Moisten with water. We ram.

- We make formwork from wooden boards to the full height of the trench.

- We reinforce the tape with wires tied into a mesh.

- Fill to the top with concrete mortar in a ratio of 1: 3: 3, where 3 parts of sand and crushed stone are required for a part of the cement.

- To get rid of voids, we pierce the base with a twig in separate areas.

- Freezing time - a week. Then the formwork can be removed.

Thematic material:

Dry masonry

When the base is ready, you should proceed to the brick ordering. For beginners in the construction business, before trying to put material on the mortar, it is recommended to build the first rows without it. Count the required number of elements. Lay out bricks dry. Make sure that the gaps between them are the same.

Mixing solution

We take cement as a basis. To prepare the mixture, combine cement with sand in a ratio of 1: 3. We add water. The consistency should be thick sour cream.

To accurately calculate the amount of mortar required, you can use a special construction calculator.

If financial resources allow, then it is worth purchasing a ready-made mixture to which you just need to add water.

Laying on mortar

For the construction of a fence, a brick thickness of 1 brick is enough. For a high fence, it is better to choose a double row.

Consider building a fence without patterns using ordinary masonry. The order of work is as follows:

- It is better to pre-soak the raw materials used in water. The adhesion of the elements in this case will become stronger.

- To maintain the masonry level, we pull the twine.

- We proceed to laying out the first rows on top of the foundation.

- We follow the same layer of mortar between the bricks. We level. The surplus must be removed immediately.

- In the corners, we set orders using nails.

If necessary, we eliminate the unevenness of the masonry.

We embroider the seams

Refers to the final stage of construction. Neat grooves in the masonry are made with a special spatula with a notch or use a bar of reinforcement. The voids between the bricks are filled with mortar.

A fashionable trend is to join joints with a colored cement compound. You can paint a small amount of the mixture in a bright tone and fill the seams with it. A white seam looks good against a chocolate brick background and vice versa. In this way, you can update buildings and give them aesthetics.

We make the ebb

A necessary measure to protect the foundation, concrete from the effects of groundwater. In addition, ebb tides are an element of the fence decor.

They are purchased ready-made in the form of concrete slabs, plastic products, metal, or they are created independently.

An important rule is that the low tide is laid at a slope of several degrees for better water flow. Equipped with artificial gutters.

To build it yourself you need:

- Close to the base of the fence, make a trench with a slope 30 cm wide, 20 cm deep.

- Align the bottom.

- Install waterproofing. Roll roofing material is suitable.

- Cover up with a sand pillow.

- Lay out the stone slabs. Fill the joints between them with concrete. Leave space for the gutters.

Fence decoration

To add aesthetics to the fence, you can use plaster or paint.

Plastering

It is not necessary to carry out, but if the idea provides, then we perform in this order:

- We moisten the brick walls with water.

- Apply a layer of 10-15 mm plaster. Let it dry for an hour.

- Let's start aligning. We take a sharp rail and walk along the surface.

- For the next 2 days we moisturize the coating to prevent cracking.

Painting

In this way, it will turn out to update the old brick fence or give a neat look to a new one.

Consider the painting technology of the new fence:

- We treat the surface with a primer. We pay special attention to the seams. We give time to fully absorb.

- We recommend using a thick brush to apply paint. If one layer is not enough, then after it dries, apply a second one.

- At the end of the finish, we treat the fence with a waterproof sealant from a sprayer. This protective solution will make the surface more resistant to environmental influences.

Coloring of the seam lines is allowed in contrasting colors.

Installing the backlight

A popular practice is to mount street lights or lanterns to a fence. The original option is to install solar-powered lamps in the form of balls on the fence posts that work without electricity. And with the onset of evening they light up with white light and illuminate the site.

If you decide to install a standard outdoor lighting, we recommend that you seek help from an electrician who can safely connect the devices to the network, properly protect the connections from moisture.

Photo gallery of finished fences

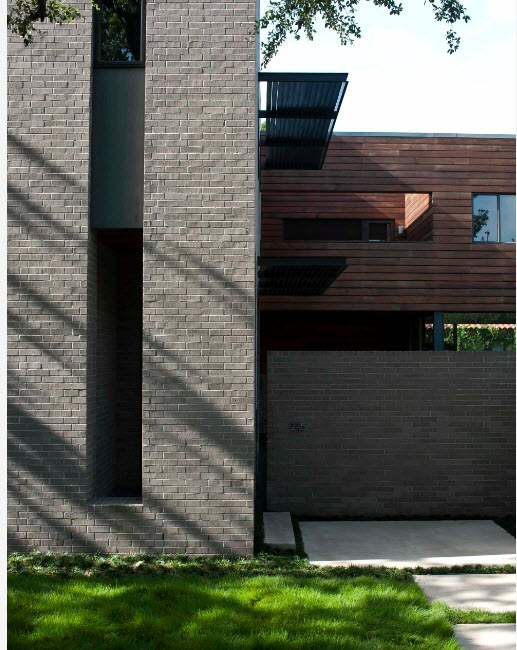

The photo below shows various ideas for brickwork, fencing design.

Building a brick fence is a time consuming process that requires patience and building skills. However, as a result, the owners get a reliable and durable fence and an aesthetic appearance.

Brick in low-rise construction will always be in demand. Even in cases where the house is built of aerated or foam concrete, many people choose facing bricks for the exterior decoration of the facade. It is also commonly used in the construction of fences. Most often they are used for poles and a base in fences of a combined type, but those who want to get a "house-fortress" build a completely brick fence.

Capital fence made of bricks Source besplatka.ua

Pros and cons of brick fence

The advantages of a brick fence, subject to quality materials and adherence to construction technology, have the following list:

- Solidity and solidity.Technologies change, other materials appear, and bricks and buildings made of it do not lose their attractiveness for connoisseurs of the traditional style in architecture and landscape design.

- Reliability and durability... In terms of the degree of protection of the site, the brick fence has no competitors. Its resistance to mechanical stress is not worse than that of forged or welded fences, but they are "transparent" for prying eyes and are not difficult to overcome. Fences made of corrugated board have blind spans, but in terms of strength, a thin steel sheet (0.45-0.5 mm) cannot be compared with laying in one brick 250 cm thick.

- Durability... The only competitor in terms of service life is concrete, but it must be additionally "decorated" to make the fence attractive. There are also fences made of cast iron, but they are good rather on the embankment or in the city park, and not around a private plot. Steel is susceptible to corrosion, and even with a protective coating with zinc and polymer paint, this process is simply delayed in time.

With proper installation, a brick fence is one of the most durable and unpretentious in operation. Source pinterest.se

- Unpretentiousness... The only duty of care is to ensure that fungus does not form on the north side or in a shaded and poorly ventilated place (but this is a “disease” of all mineral building materials and wood).

- Wind and road dust protection... Of course, these influences are not completely blocked, but their influence is significantly reduced.

Such a fence also has disadvantages. But they are exclusively economic in nature:

- High price piece material... Especially foreign made.

- High costs of paying builders... Building a brick fence is almost like building the box of a small house with the same area of \u200b\u200bload-bearing walls.

- The need to equip a strip foundation along the entire length of the brick fence.

Brick types

For the construction of a fence, different types of bricks are used. And they often use the type that was chosen for the construction or cladding of the house:

- Ordinary ceramic bricks. The price of one starts at 5 rubles. It has low decorative properties and is rarely used in the construction of fences - only for plastering or tiling.

Fence made of "classic" ordinary brick Source aviarydecor.com

- Fence cladding brick... Among ceramic bricks, it is next in cost after ordinary. And the most popular in the construction of fences. The price of one is in the range from 8 to 17 rubles.

Construction of a fence made of facing bricks Source stroidom.info

On our site you can find contacts of construction companies that offer the service of building fences and barriers. You can communicate directly with representatives by visiting the Low-Rise Country exhibition of houses.

- Clinker... Another type of ceramic brick, but made of more refractory clay. Due to the characteristics of raw materials and high-temperature firing, its strength is one of the highest among the building blocks. For a domestic manufacturer, the cost of a single brick starts from 20 rubles. Facing clinker from Europe can cost up to 90 rubles. a piece.

Clinker brick fence Source nadoremont.com

- Hand molding... According to technology, this is a classic ceramic brick, but as a handmade product it is expensive. And in order to justify the high price, manufacturers try to compensate for it with the original texture. The unit cost is on average two times higher than that of clinker, but there are other size standards (smaller ones), so the cost per square meter of masonry can be 3-4 times higher.

Hand-molded brick fence looks very impressive Source sladkiyson.net

- Silicate brick... Due to its almost perfect surface, this type of ordinary building block can be used as a front block, although there are also bricks with an improved surface. An ordinary "white" sand-lime brick for a fence will cost from 7 rubles, front - 10-20% more expensive, you will have to pay the same amount for the color. The most expensive silicate brick with a chipped surface is from 20 rubles. a piece. In the photo below, a white brick fence with additional stone trim.

Light sand-lime brick fence with additional stone trim Source stroitelcentr.ru

- Hyperpressed... Its composition differs from silicate brick in that cement is used instead of lime. And according to the production technology, it is hard concrete of semi-dry pressing. It has other formats, and if we compare the prices per square meter, then with a smooth surface it will cost like an expensive facing brick, and with a chipped one - 2 times more expensive. This type is rarely used, more often decorative concrete blocks for pillars and fences are chosen.

A fence made of hyper-pressed bricks requires high skill of a bricklayer Source moidachi.ru

Varieties of brick fences

If we talk about "pure" brick fences, then they can be classified by the thickness of the masonry. And this division makes sense when it comes to standard building block formats. For example, laying in a "half brick", "one brick" or "one and a half bricks" means a wall thickness of 12 cm, 25 cm or 38 cm.

Note! The thickness of the masonry in "bricks" is a multiple of a spoon (brick length) of a single format (1NF) - 250 mm, and not a poke (brick width) (120 mm). When using other formats, including European ones, an individual approach is needed to calculate the thickness and calculate the required quantity.

In the construction of fences, two types of masonry are most common - in "half-brick" and in "brick".

The choice depends on the priorities;

- In the "half brick"... The most economical laying. The strength of the fence is considered sufficient provided that its height is no more than 2 m, and the distance between the posts is 2.5 m.

- Into the "brick"... The optimal type of fence in terms of strength and brick consumption.

Masonry thickness of brick fences Source dp32.ru

It is impractical to make a fence around a private house thicker, "one and a half bricks" - more costs for materials and work, more powerful foundation, and with a relatively low masonry height and the presence of support pillars, the span strength is excessive.

Technology Basics

The construction of a brick fence combines two construction technologies - pillars and spans, which differ in the type of masonry (methods of dressing). But regardless of their configuration, the sequence of work has a strict sequence. And at the first stage, the foundation is poured:

- Planning a plot... The marking is carried out taking into account the size of the pillars and the layout of the building blocks in the span - its length should be a multiple of the size of the spoon (plus the thickness of the vertical seams). With the usual dressing of the masonry on the brick floor, every second row should end with the second half of the block from which it began.

- Excavation works... A monolithic strip foundation for a fence can have a different profile in depth - it depends on the nature of the soil and the design load. A base is made under the pillars with a heel below the level of freezing of the soil, for spans - they can be limited to a depth of 50-60 cm.

One of the options for the foundation for a brick fence Source stroim-dom.radiomoon.ru

- Formwork is installed and reinforcement is carried out... For pouring concrete, the most common removable formwork made of edged boards or wooden panels is used. When reinforcing the base for the post, a volumetric frame is usually used with an outlet to the height of the steel pipe fence. The tape under the span is reinforced with a frame of four longitudinal reinforcement rods with strapping with transverse and longitudinal bars of a smaller diameter (the main task of the armopoyas is to accept fracture loads).

- Pouring concrete... The fence, albeit a stone one, belongs to light buildings - the M200 brand is enough.

In terms of the total cost, the cost of manufacturing a monolithic foundation for a fence starts from 4000 rubles / m 3.

After the concrete has matured, the pillars are built. In section, this is a well masonry of one and a half or two bricks around the pipe. The empty space that remains inside is filled with mortar as the column is erected. For combined fences, embedded elements are installed for the installation of crossbars; for purely brick fences, such elements are needed to fasten wickets and gates.

Video description

See the video clearly about the foundations for a brick fence:

The total cost of one column 2.5 m high starts from 12,000 rubles. - taking into account the foundation (depth from 1.5 m), mortar, concrete or steel cap, domestic single facing brick at a price of up to 15 rubles. a piece.

After the construction of the pillars, spans are laid out between them. The first row is first laid out "dry" in order to adjust the thickness of the vertical seams. Then the span is filled with a brick in the dressing, using a template to form the seams. The cost of laying a span of half a brick is from 650 rubles / m2.

After the masonry mortar has set, jointing is carried out, and the top is laid out with a brick or a ready-made parapet is installed.

Video description

Visually about the construction of a brick fence in the video:

Video description

65 ideas for a beautiful brick fence, see the following video:

Conclusion

A brick fence is one of the most difficult and costly types of fence. Errors in calculating the foundation and pillars are difficult to correct, and sometimes impossible - this is not an easy fence made of mesh or plastic. Making such a fence with your own hands is like laying a brick on the wall of a house, and such work should be done by professionals. The customer's task is to choose the type of brick and the design of the fence - there are different options for color combinations, the use of shaped elements to create an architectural decor, decorating parapets and pillars with forged accessories.

Owners of country or city private houses sooner or later face the need to fencing their territory. Among the many options for arranging a fence, many choose brickwork as the main material for execution. And there are many reasons for this. If you are thinking about choosing a material for making a fence for a private yard, summer cottage or personal plot, then this publication is for you.

Advantages and disadvantages of building a brick fence

The obvious advantages of using brickwork to create a fence include:

- long service life - a brick fence can easily be inherited not only by your children, but also by your grandchildren, because masonry made of high-quality material is not afraid of climatic manifestations and temperature drops;

- during operation, a brick fence does not require practically any maintenance, if the material is of high quality and new, then no painting or any other surface coatings are needed;

- a brick fence has high reliability and durability, is able to protect the site not only from prying eyes, but also any external manifestations (provided that the fence is of sufficient height);

- the ability to independently choose the height of the fence;

- aesthetic appearance - a brick fence can not only become a reliable fence, but also a decoration for landscape design, a spectacular completion of the image of your architectural ensemble;

- the ability to create a non-trivial design - simple brick canvases can be diversified with decorative inserts, arches, columns (pillars);

- the presence of variations in the execution of a brick fence makes it an almost universal option for any stylistic design of the building facade.

But a medal always has two sides - a brick, and therefore a fence made of this material has disadvantages:

- the rather high cost of both the material itself and the work on its installation (therefore, many owners of private houses with land plots choose the option of combining bricks with other, cheaper materials);

- when using second-hand brick (in order to save money), the service life of the fence is significantly reduced;

- for the construction of a really strong and durable brick fence, it is necessary to lay the foundation, which increases the term of work and the overall estimate.

Classification of brick fences

Fences, which are brickwork in one or another modification, are subdivided according to the following criteria:

- type of foundation - strip (used most often) or columnar (used only in the case of a small thickness of masonry) foundation;

- the thickness of the brickwork - varies from a size of half a brick to three bricks (it is important to understand that its reliability, strength and durability directly depend on the thickness of the fence);

- the height of the brick fence is a relative value, but usually ranges from 50 cm to 3.5 m (the higher the fence, the greater its thickness should be to ensure the necessary stability);

- the presence of pillars (largely depends on the length of the spans and the views of the site owners about the beauty of the fence);

- the type of material to be combined with (if any).

Let us dwell in more detail on the possible options for combining bricks with other materials. To give the fence more originality, and sometimes to reduce its cost, speed up installation work, you can use combinations with the following materials:

- brick and metal forging;

- wooden picket fence, boards or lattices made of wood;

- metal picket fence or sheet material, metal profile (budget option in combination with brick pillars);

- combination of building bricks with decorative, chipped ("torn");

- in rare cases, you can find a combination of brick and masonry (rather expensive fencing).

Brick and metal forging

In combination with metal forging, the brick looks luxurious. Forged elements can be used exclusively as a decor for a solid brick wall or be an integral part of it, acting as a material for canvases or intermediate links.

Elements of metal forging can be of different shapes and sizes, located on the fence in different ways, depending on this, there are three types of brick fence design:

Parapet. Forged rods and decorative elements are installed on a solid brick canvas (the height of metal structures is not more than half a meter, as a rule). The fence turns out to be not only beautiful, but also reliable from the point of view of the possibility of outsiders entering the site;

The base is combined with forging elements. The plinth can have a height of 30 to 150 cm; forged metal structures of various modifications are installed on it. Most often, through such a fence, you can see what is happening in the yard or on the site;

Brick pillars plus forged items. The main part of the fence is forging, set on a base no more than 30 cm high, while brick is present only in the composition of pillars or columns. Often, when erecting brick pillars, metal reinforcement is inserted into them (to give the structure more strength and reliability).

Combination of brick and wood

The combination of brick and wood does not always reduce the overall cost of the fence. Only if you already have wood in stock and you need it, which is called "attach" with benefit. Usually, the combination of brickwork and wood elements is due to the need to create a harmonious image of the entire architectural ensemble with the adjacent territory. If wood is used in the facade of the main building, other buildings or elements of landscape design, then it will be logical to use it to create a fence for the site.

If it is not so often possible to find wooden elements in the composition of the fence itself, then the use of wood for the manufacture of a wicket and even a gate to a brick fence is a very popular phenomenon. Brick in many ways symbolizes urban and even industrial style, and beautiful wood carvings or deliberately aged boards seem to soften the image and balance the overall picture.

Choosing a brick color palette for creating a fence

The modern assortment of building materials is striking in its variety. The rich color palette of bricks, especially facade, facing, can become a reason for some confusion for owners of private dwellings who want to protect their plots. From snow-white and light gray to dark brown and burgundy, brick as a material for creating a fence can both support the overall color scheme and become an accent element in the image of the entire structure and the surrounding area.

One of the most popular ways to select fencing bricks is by repeating the material used for the façade of the main building. The use of bricks of the same color scheme for the house and the fence leads to the creation of a harmonious image of the whole ensemble. Most often, you can find bricks of almost all shades of red, with a predominance of reddish shades. No wonder the name appeared in red-orange color - it is often called "brick".

Brick of all shades of yellow and orange looks no less impressive, but at the same time more restrained ...

A brick of wine color or shade of Marsala looks luxurious. As a rule, a fence with such a color scheme becomes an accent element of the architectural ensemble.

Gray brick is usually chosen if the building and landscape design of the area is made in a modern style and even with an urban bias. If concrete is actively used in the design of a site or yard, then a brick fence of any shade of gray will look more than appropriate.

Brick for fencing a private yard or summer cottage can be chosen to match the color of garden paths and areas (patios), if they are also made of this building material. In this case, the facade of the main building (house) may differ not only in color, but also in the material of execution itself.

Brick as a building and facing material does not require subsequent painting or any other coating. Provided new material is used. In the event that used brick is used to extend its intended juice of service, the protective coating will not damage. In some cases, painting is necessary to create a balanced image of the entire ensemble - the household and the area around it.

And finally - some original ideas

The fence "with perforation" looks original. The brick is laid out not in a continuous canvas, but in a checkerboard pattern. As a result, the fence has holes through which you can partially see what is happening on the street and in the yard. The fence turns out to be less durable, more decorative, but still capable of protecting the territory from external influences (except for prying eyes).

A low brick fence can serve as a garden bed or flower garden. As a result, the site is decorated with an original element of the landscape, and it is easier for plants to provide the care that is necessary for each specific crop.

In some cases, the fence has not so much enclosing as a decorative function. As a rule, a low fence is present inside large-scale plots to enclose the functional segments of the plot. Such zoning not only brings order to the clear delineation of the yard or personal plot into sectors, but also decorates the landscape. A low brick fence can serve as a curb - to delimit areas of garden paths and flower beds or beds.

Is an important safety issue. Most owners try to make and install a fence on their own, or turn to the services of professionals. To make a decision, you can turn to ready-made options, borrowing ideas from the designers, or implement your own project. There are many types of fences to fulfill different purposes. A few tips and inspirational designs in the photo will help you create a good solution and choose an individual design.

With your own hands

After deciding to build a brick fence with your own hands, it's time to go to buy the necessary materials. Reinforcement is used as the load-bearing component on which the brick wall is supported. To fix the bricks you need cement, sand and crushed stone. Depending on the size of the masonry and the height, it is determined which type of brick is advisable to use.

The construction of the fence begins with the installation of fittings and guides. Previously, the entire territory must be cleared of weeds, gravel and other building materials. Fence posts are located around the entire perimeter at a distance of 1.5 meters. Be sure to monitor the resulting parameters. The pillars must arrange right angles, otherwise the fence will turn out to be crooked.

The best option for self-assembly is the use of tape base... We dig out a trench and install the formwork. Sand is filled in, forming a special pillow. Fittings are mounted on top. When the base is ready, concrete can be poured into the basement. The curing process depends on the materials used and the installation depth. Universal parameters 50 cm long and 25 cm wide.

When the concrete is ready, you can move on to laying the bricks. High-quality waterproofing is used between concrete and brick. The use of mastic is recommended. The universal way of laying - single-level design with a shift in half the brick length... It has a beautiful classic look. If you wish, you can create decorative patterns yourself. There are a large number of independent options for laying the fence.

Plus metal elements: picket fence or forging

Plots with living quarters require a beautiful "cut". The best option for a private house would be a brick fence. It is a solid construction that has served for many years. A brick fence is a rarity today. This is not only expensive, but also not always justified from a design point of view: such fences are heavy, monumental, and hide the beautiful facade of the house. Therefore, you can often find combined fences. - it looks quite respectable, and at the same time it is quite reliable and relatively cheap material.

The fence looks exquisite with additional small inserts made of colored bricks... Several different materials can be used in the expansion. To create a classic version, the pillars and parapet are faced with bricks of the same color, and the span is made of multi-colored bricks, or from another material. It is possible to soften the structure by using an inclined masonry from another brick.

Drawings and decorative patterns made of colorful bricks give the fence an elegant style. It is recommended to combine with forged elements, peaks... You can choose an interesting option separately. Now forged inserts of various types are sold in any construction market. The forging is mounted on top of the fence, or below. The fence looks original, where they are made of the same forged material as the decorative elements.

Yellow and brown brick fences

The question of using yellow or brown bricks is an aesthetic privilege. The latest fashion trend is the combination of the original colors of the brickwork of the house and the fence. Speaking of technical characteristics, yellow or brown brick does not differ from red in anything other than color. It has high safety, reliability, long service life, and fire resistance.

For down-to-earth people, it is recommended to use the solid color version, which helps to save a decent amount of money. All of the above functions are preserved. Only additional decor is lost. There are many options for masonry from yellow and brown bricks.

Brick of dark shades looks beautiful plus light grouting.

As a small decor, the owners use forged elements over the main masonry. For maximum safety, it is recommended not to use forging between brick fences. In this case, the fence serves more an aesthetic function than security. Although it has a definite plus: usually a wonderful view of the garden opens up through the bars, the entrance group of the house.

Combined brick and wood fence. The yellow pillars of the fence posts are perfectly combined with the facade masonry, maintaining the unity of style.

Fences made of stone and brick

Used as a decorative element. These are natural breeds of the following type:

Clinker brick

Clinker bricks are recognized as an environmentally friendly building material. In terms of strength, it is not inferior to the famous options. Each brick is made of clay that has been pretreated with high temperatures. It has a low rate of moisture absorption, firmly transfers external negative environmental factors. Long service life established.

Clinker material can be organically used with natural materials: stone or. The material is suitable for independent use. First, you need to clarify the features of working with clinker bricks and master the masonry technique. First of all, a foundation is laid from a prepared concrete mixture. Between the poured foundation and the subsequent laying, a horizontal type of waterproofing is carried out. It is recommended to use roofing material. It helps protect your fence from moisture, insects and pests, and other environmental influences.

In the second stage, laying begins from the bottom rows from the corner surfaces. It is recommended to use masonry mortar to fix the bricks. When using multi-colored bricks, you need to remember the layout order. It is impossible to make mistakes, as it will take a lot of finances to alter the fence.

White brick

White brick is the most demanded material in the construction of any facility. Silicate brick - the second name. Thanks to its impressive characteristics, durability and other building parameters, it is an inexpensive option that allows you to build any object. There are many options in the design of fences:

- The classic version. When one sand-lime brick is used and a single classic masonry is used without decorative elements. It is a robust construction designed to provide the highest level of safety. In some cases, sand-lime bricks are covered.

- The second option provides use of several decorative elements at once... The prices for such modifications are higher, but visually they win in relation to the classic versions. Brick columns are combined with brown polycarbonate canvases. Visually, the option resembles a castle from a fairy tale.

White brick and forging

Pillars and Columns

There are several types of brick columns, depending on the functional load:

Compilation on video

Photos of beautiful (and judging by their appearance - rather expensive) fences made of brick, stone, forged elements.

Many people have suburban summer cottages where they can take a break from the bustle of the city and put themselves in order. But the rest should be comfortable and, first of all, safe. To achieve this result, you need to enclose your area with a fence. And the best option in this situation is the installation of a fence with brick pillars.

The idea

Before starting such a large and ambitious project, you should familiarize yourself in more detail with all the proposals that companies can offer for the construction of these structures.

In order to find them, you don't have to go to every store and check all the details. Using the world wide web, you can find information and photos of a brick fence, and any other information regarding this product.

The main thing is to correctly analyze the market and choose the product that suits the most.

The foundation

Before starting laying a brick fence, a person needs to select the material that will be used in the construction of this structure. After all, we can say with confidence that a fence is not only a method of protection. It can also be used as an element of external decor.

Thanks to its presentable appearance, he will be able to make up a whole design ensemble together with other objects at his summer cottage.

Therefore, for this there is a large number of different types of bricks. Here are some of them:

Facing brick

A very popular material on the market. Due to its versatile properties, it has the ability to add unique lines and original design solutions during the masonry process. This brick can take the form of any material, and it also does not need final processing. The color palette is huge and varied.

Chipped brick

Brick, the main purpose of which is decor. Quite an expensive model, so most often it can be found on the buildings of wealthy people. Possesses good strength characteristics. Due to its shape, it can give the fence an unusual look.

Ceramic bricks

It differs from a conventional product by the presence of roughness on the surface. Available in various color tones, which allows you to give the design a unique and inimitable look.

Silicate brick

The classic is silicate brick. An economically viable option, in terms of strength and power, not inferior to the richer "brothers".

Of course, in appearance it does not reach the level of expensive models, but if you decorate it beautifully, you can get an effect that will be in no way inferior to fences from expensive estates.

Clinker brick

Expensive, but at the same time one of the most trending materials in our time. Most often they attract people with their appearance and great installation possibilities. Clinker bricks are made using special clay and are not inferior in strength to other types.

Due to the absence of internal voids, it can last for decades, but due to the complexity of manufacturing it is quite expensive.

Hyper-pressed brick

Well, a completely new trend is a protective structure made of hyper-pressed bricks. The main differences are - resistant to environmental changes, durable, environmentally friendly. The material is made in various colors.

Pros of brick

Before pouring the foundation under a brick fence, you need to understand if it has any advantages! Or it may be worthwhile to wait and weigh your decision more carefully. But if a person has already decided on the construction of this particular structure, then he will certainly not fail with his choice.

A brick fence has a number of important advantages that distinguish it favorably from other analogues. These include:

Reliability. A fence made of such material will serve as an excellent protection from “accidental” guests and the looks of curious neighbors.

Long service life (at least 10 years). With proper use, such a fence will stand for a long time and will serve not only those who built it, but also their children.

Thanks to the brickwork, such a structure will easily withstand any natural disaster (of course, within natural limits) and will not be envious of changes in the temperature environment.

Attractive look. A fence can be built not only for the sake of protection, but also for the sake of decorating the square, because a large number of different ideas can be embodied on it. For example, add small arched arcs or weighty columns to the structure.

If we consider a brick fence as an investment, then this is the smartest move that a person can perform.

DIY fence installation

If a person has a number of specific skills, then he can easily make a brick fence with his own hands. To do this, he will need patience and an auxiliary construction tool:

- trough for solution preparation;

- mixing shovel;

- a hammer;

- bulgarian;

- rope;

- cement;

- fittings;

- sand;

- putty knife;

- crushed stone;

- water;

- buckets.

Do-it-yourself fence installation can be divided into several stages:

- stage one - collection of construction tools;

- stage two - the choice of material;

- stage three - review of recommendations related to general design;

- stage four - marking the site;

- this fifth is foundation pouring;

- stage six - brick laying;

- the seventh stage - the final cleaning of the defects.

Issue price

The price of a brick fence can be very different, because each company sets its own conditions. On average, the price of a fence starts at 500 rubles per m / n. More expensive options start at 5,000 rubles per m / n.

Photo of a brick fence