Assembling a ship model can be interesting not only for avid ship modelers, but also for beginners. Collecting a wooden model, you will learn a lot about the construction of ships, enjoy seeing how a set of wooden blanks turns into a real sailboat. For a pleasant build, we recommend starting with the simplest models. Call us - we will be happy to help you with the choice.

Each wooden ship is unique and often carries a piece of history. We have colonial ships, fishing vessels, and majestic warships - for every taste and color. We offer quality models at low prices - these are foreign models of the brands Mamoli, Corel, Mantua, Amati, Artesania Latina, Billing Boats, Constructo, and ships for assembly from Russian manufacturers - Master Ship, Falconet, LS Model.

What's inside?

Each kit contains materials, drawings and instructions - in general, everything you need to assemble a model of a wooden ship. On the other hand, tools, as a rule, are not included in the kit - this allows you to save money for those who already have tools. For everyone else, our store offers a wide variety of modeling tools. Usually, everything that needs to be purchased to build a model "from scratch", we indicate in the subsection "related products" on the product page.

Content

Recently, decorative items that are created from recycled materials or from materials that are conventionally called garbage, for example, cardboard boxes from under equipment, are in fashion. On the other hand, it has become fashionable to create various figures and models of equipment out of paper. In this article we will try to create some interesting cardboard ship models. For some of these models, you will need ready-made templates, and some products can be created without diagrams, using your imagination. At the end of the article, you will definitely find a video tutorial that will help you consolidate your knowledge and create an interesting product from improvised means. Let's not waste time, prepare materials and start creating.

Templates

Let's start by trying to create a ship using templates. They are easier to work with. What you need:

- thick cardboard (you can use an old box);

- scissors;

- pencil;

- ready-made template;

- glue or tape;

- colored paper and other decor.

First you need to print the template and transfer it to the main material. By the way, if you are using cardboard that is not too thick, then the template can be printed directly on it.

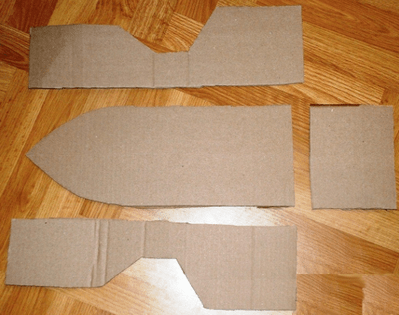

You should get about the following details:

Next, you need to dilute a little PVA glue with water, cut ordinary paper into pieces and, dipping them into the solution, glue them to the base of the ship. Remember the papier-mâché technique. It is better to connect the parts of the ship themselves with tape.

It remains now to arrange the blank with the prepared decor. It can be colored paper, wrapping paper, fabric. The ship can also be painted with regular watercolors.

You also need to make a mast for the ship. You can use a regular twig and some thick cardboard round timber.

Any boat must have a flag. For it, use a cloth and applique made of paper or material. The sail can also be made of cardboard, use toilet paper rolls.

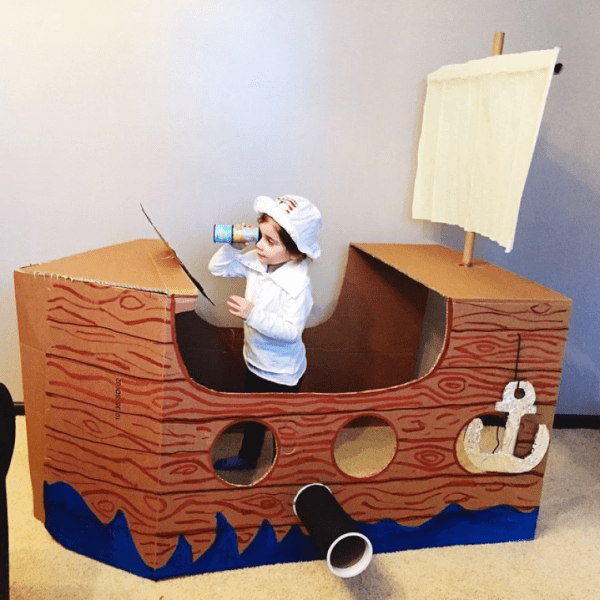

Making a big ship

This option is suitable for young children who like fun games. For such a ship, you will need a large box. It can even be packaging from under the refrigerator or from a large TV.

First, you need to connect the box valves and make the boat's sharp bow. On the sides, you need to cut a few rounds to make improvised portholes. Use a thick stick and cloth to make a flag. Use paints to paint the ship.

Do not forget about details such as the anchor - it also needs to be made of dense material and decorated. A large cardboard ship with your own hands is ready to sail through the endless expanses of the apartment.

We use matchboxes

Let's call this modeling, because we will create an entire ship from several matchboxes. What you need:

- cardboard;

- glue;

- matchboxes;

- wooden skewer or thick paper;

- colored paper;

- felt-tip pens;

- scissors.

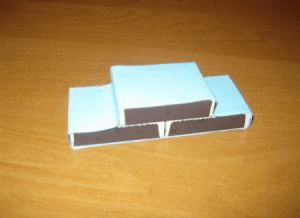

First you need to glue together two matchboxes with short sides. Glue another box on top in the middle.

Now you need to cut out a rectangular piece of paper and glue it on top to the structure.

Now we need to cut a strip out of thick colored cardboard, with the help of which we will shape the bow of the ship.

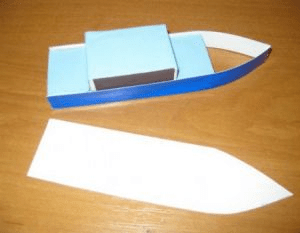

Now you need to cut out a piece of cardboard that will correspond to the contours of the ship, take a look at the photo:

Now the bottom and top of the ship need to be held together with glue. Next, you need to make a mast. You can use a wooden skewer or twist the A4 sheet very tightly and secure the tip so that the sheet does not unwind.

A hole must be made in the upper matchbox of the ship so that the mast can be inserted. Remember to use glue.

Now it remains to cut out the sails from colored paper, paint them and attach them to the mast.

The matchbox ship is ready! It can be made wider and taller by using more matchboxes. If you use very thick cardboard for the bottom of the ship, then it is quite possible to launch it on the water and participate in competitions for the title of the fastest boat.

DIY cardboard spaceship

We suggest using a fairly simple option that will literally create a 3D model. To do this, you need to cut out several identical parts from cardboard, but in different sizes. The parts must be fastened together, but between them, either a thin piece of foam rubber, or a small piece of thick paper. It will look something like this:

Or like this:

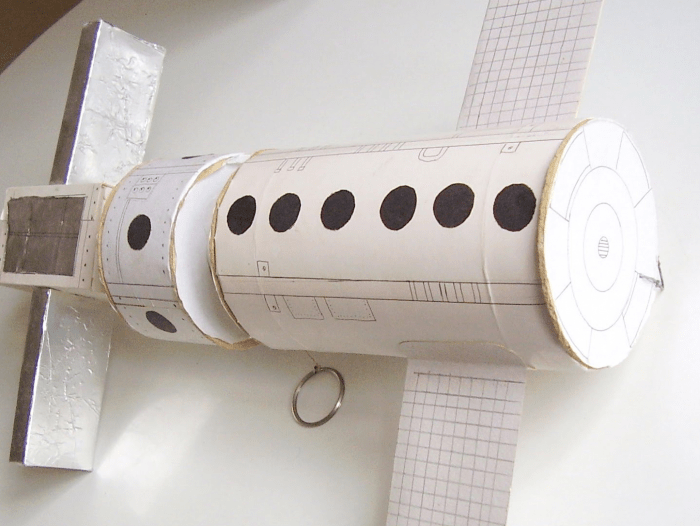

An entire space station can be made using cardboard toilet paper and duct tape sleeves.

Use silver foil, a pair of compasses, a black felt-tip pen, and a simple pencil to give the spaceship a realistic look.

Cardboard is a fairly convenient and easy-to-use material, but if you know a few nuances, the work will seem even simpler, and the product itself will turn out to be neat:

- when working with very dense material, use fairly sharp scissors, or even better, a clerical knife;

- before bending the cardboard parts, it is better to draw along the dotted lines with the not sharp side of scissors or an old pen that does not write, then the material will bend neatly and evenly;

- not in all cases a glue gun can be used. For example, if you work with thin material, then it is better to use office glue or PVA;

- work in a room where the humidity is not too high, otherwise your products may exfoliate or parts may not stick together;

- the room should be light, it is desirable that there is a window that can be opened and ventilated;

- and we always advise you to work only in a good mood.

How to make a ship out of cardboard with your own hands - a few more interesting options

We would like to offer some more interesting and beautiful options for ships that you can make with your own hands.

In this case, a milk carton, cartons and sleeve are used.

And this is a luxury boat made from a regular cardboard box.

With a little practice and imagination, you can end up with such a beautiful pirate ship made of cardboard with your own hands. We always advise you to involve children in your creativity. They will be especially pleased to know that they are creating a boat just for themselves. In parallel, you can think of a pirate costume, as well as make a telescope, a hat and a cardboard knife out of cardboard. Such participation of children in creativity helps to develop their imagination, attentiveness, perseverance, the desire to create something for themselves with their own hands. Be sure to involve children in cleaning. Explain to them that you need to put all the materials behind you, put them in their places, and also need to clean the workplace so that you can do your creativity again later.

For lovers of modeling, sheets of pressed and glued wood veneer have always been one of the most demanded materials. They are easy to cut, perfectly processed, drawings of ships made of plywood are easy to find on the net, and therefore it is from plywood patterns that many craftsmen begin their acquaintance with the modeling of various ships.

Making models with your own hands is a very difficult task, requiring a significant baggage of knowledge and a certain skill. In the article we will tell you only about the most basic techniques, and you will hone your further skills yourself.

Materials for work

If you want to make a small ship model, then you will need the following materials:

- Wood - cedar, linden, walnut, or other wood, preferably soft and not fibrous... Wood blanks must be even, free of knots and damage. Wood can be used both as a material for the main elements of the model (hull, deck) and for fine detailing.

- Plywood is perhaps the most demanded material... For ship modeling, either balsa or birch is used, since it is these types of wood that provide the minimum amount of chips when sawing. Model ship plywood is typically 0.8 to 2 mm thick.

Note! Beech veneer sheets of small thickness are sometimes used as an alternative to birch: although they are inferior in strength, they bend much more easily.

- Veneer - thin plates of natural wood of expensive species... As a rule, it is used for veneering, i.e. pasting a surface from an inexpensive material.

- Fasteners - fine chains, laces, threads, brass and copper studs.

In addition, we will definitely need wood glue, cardboard and tracing paper for transferring templates, etc. Fine detailing is made from metal casting. As an alternative to metal, you can use colored polymer clay.

Making a souvenir boat

Preparation for work

Any work begins with preparation, and modeling will by no means be an exception.

- First you need to decide what we will build. If you have not previously dealt with the art of ship modeling, then we recommend downloading the drawings of the ship from plywood on the network: as a rule, they contain all the necessary information and are understandable even for a beginner.

Note! Kits are available for sale that allow you to assemble a boat from ready-made parts. Beginners will be interested in such kits (although the price of most of them is very significant), but it is better to master the technology from scratch.

- After analyzing the drawing, we check if everything you need is in stock. In principle, if something is missing, you can buy it a little later, because building a ship (albeit a miniature one) is not a quick business!

- Having printed the drawing, we make templates for the main parts.

- Transfer templates to.

Cutting and assembling parts

You can cut the workpieces both with the help of a manual and with the help of an electric model jigsaw.

The latter is more expensive, but with it you will suffer less when cutting out small parts:

- We make a starting hole in the plywood sheet, into which we insert a file or jigsaw blade.

- We cut out the part, trying to move exactly along the marked contour.

- We process the sawn-off workpiece with a file, removing small chamfers at the edges and removing inevitable chips and burrs.

Advice! Working on one element (deck, sides, keel, etc.), we immediately cut out all the parts necessary for assembly. This way we will spend significantly less time, and the work will progress faster.

When everything is ready, we start assembling our ship.

- First, we put on the transverse frames on the longitudinal beam - the keel. A groove is usually provided at the bottom of each frame for attaching to a plywood keel.

- For connection, you can use standard glue, or you can use special glue mixtures intended for ship modeling.

- We attach the upper parts of the frames to the deck. For simple models, the deck is one sheet of plywood, while for complex models it can be multi-level.

- After the glue on the frames has dried, we begin to sheathe the sides with thin strips of plywood. The thickness of the material should be no more than 1.5 mm, since only in this case will we be able to bend the skin without the risk of damaging it.

- Can be heated and humidified for bending. After that, the material will bend without difficulty, and over time it will acquire a stable shape.

Note! The body for painting can be pasted over with a solid sheet. But to imitate plank sheathing, it is better to use strips up to 10 mm wide (depending on the scale).

- We fix the glued plywood with clamps and clamps and leave to dry.

Final finishing

By and large, this is where the carpentry skill ends, and the art begins.

When the body is assembled and dried, we need:

- Fabricate from thin plywood and secure deck superstructures.

- Build up the sides so that they protrude above the deck plane.

- Paste the surface of the deck with a wooden veneer or outline it with an awl, imitating the boarding.

- Make and install all the small parts like the steering wheel and steering blade.

- Fasten the masts with all additional devices (the so-called spars), set the sails and stretch this entire structure with the help of the rigging threads.

Finally, all plywood parts need to be stained and varnished. This will provide our souvenir with at least a couple of decades of preservation.

Conclusion

Almost everyone can make a simple boat out of plywood with their own hands - enough patience and minimal skills in working with a jigsaw (read also the article). But if you want to implement a complex drawing with many small details, then you will have to work hard. This is why we advise you to start with the simplest models, gradually building up your skill!

In the video presented in this article, you will find additional information on this topic.

Similar materials

In modeling, plywood is the most demanded material. This is due to high quality indicators, as well as ease of operation. Plywood sheets are very easy to cut, quite simple to process. Using a suitable scheme (drawing), you can make ships out of plywood with your own hands.

Plywood is a versatile material that can be easily cut and processed in various ways, therefore it is with plywood patterns that it is recommended to start your acquaintance with modeling.

Building a ship yourself is a pretty interesting experience. But in order to start performing complex models, you need to practice on the lighter ones.

Materials and tools

To create stucco patterns on board the ship, you need to prepare your own composition, from which you can form reliefs. The following tools and materials must be prepared for the solution:

- wood dust;

- PVA glue (on average, one ship model can take about half a liter of glue);

- plasticine for creating small irregularities and patterns;

Materials and tools used during ship simulation:

Birch plywood will provide a minimum amount of chips when sawing.

- plywood of the required thickness;

- Super glue;

- sandpaper for surface treatment;

- nylon thread;

- jigsaw for cutting out parts;

- construction knife;

- wood for the mast. It is better to use pine, as it is much easier to process;

- dye;

- small brushes;

- Chinese sticks;

- sail fabric;

- a thread;

- pencil ruler.

Modeling wood should be soft, not fibrous. The most popular options are cedar, linden, walnut. All wooden blanks must be perfectly flat, without knots and damage. It can be used as an additional element to create decorative pieces. Also, wood can be used to create the main elements of the model, such as the deck, hull.

Plywood in modeling is the most demanded material. In such a direction as modeling, birch or balsa plywood is most often used. This is due to the fact that these types of wood practically do not chip during sawing. To make a boat out of plywood, it is necessary to use sheets with a thickness of 0.8-2 mm.

A simple diagram of a plywood ship model.

Veneer - sheet material, very thin, made of valuable wood species. In most cases, veneer is used as a facing material. They are pasted over products that are made of inexpensive material.

Fasteners will perform not only the main task of fastening parts, but also perform a decorative role. To create a model of a boat, you need to prepare thin chains (several sizes can be used), laces, threads, copper or brass nails. In order to transfer the drawing from the sheet to the plywood, it is best to use tracing paper and a pencil. This will make the drawing detailed. Use glue to hold the plywood together. Fine detailing can be made by metal casting, use polymer clay, or independently prepare a solution from wood dust and PVA glue. After complete drying, such a mass is very durable, and it can be painted in the desired color.

Back to the table of contents

Preparatory work

If this is the first time a plywood ship is being modeled, it is recommended to purchase kits in which all the details have already been cut and processed. But its cost can sometimes be quite high. Therefore, with a great desire and diligence, experience can be gained in the process of carrying out work on assembling your ship. Modeling, like other types of work, necessarily begins with the preparatory stage. The first thing to start with is what kind of ship will be modeled. To begin with, it is worth looking at the various drawings and finished works, this will greatly facilitate the choice of the model.

After examining the entire drawing, it is worth checking the availability of all the necessary materials and tools to complete the work. Modeling ships is a jewel case. It takes a lot of time and perseverance.

At the preparatory stage, it is necessary to make paper or cardboard templates for all parts. After that, they are all transferred to plywood. At this stage, the preparatory stage of work can be considered completed.

Back to the table of contents

Manufacturing of parts

In order to make all the parts, cut them out of the plywood sheet, you must use the appropriate tool. You can use a hand jigsaw for work, but if possible, it is better to use an electric model option. The use of the second option will significantly reduce the time for the manufacture of all elements. This is especially true for the smallest details.

The sawn workpieces are processed with a file, removing chips and burrs.

In order to cut out a part, a hole is made in the plywood, into which the jigsaw file is located. It is worth cutting out all the details very carefully, while observing all the contour boundaries, since inaccurately cut details can then spoil the appearance of the entire ship. Each sawn-off workpiece must be filed from the ends. In the process of such stripping, it is necessary to remove a small part of the chamfer, where chips and burrs have formed. When cutting, this moment cannot be avoided.

You need to assemble the ship when all the parts are cut out and the ends are processed. This will allow you to do assembly work without being distracted by cutting out missing parts.

Some people have a strange but very remarkable and colorful hobby. It is called the assembly of ship models from wood. What does it take to make such a beautiful thing. It is not so easy to create a model from a tree. In this article, you will learn how to create from wood with your own hands. And also we will make a short excursion into history.

Francis Drake

Many history buffs know the name of the "Iron Pirate"; his homeland was England. He became the captain of a sailing ship at only 16 years old. At first he was a ship's priest, and then a simple sailor. But his fame really thundered when he became a brave and very formidable pirate. In the 16th century, he made quite a few voyages and took part in a considerable number of battles.

Golden Doe

At the time of the dawn of fate, several sailing ships arrived at his property. Its main flagship was the Pelican. This ship was a five-deck three-masters. On board there were 20 artillery weapons. All sorts of maritime stories rarely tell us that a ship that already has a name can be renamed, but it was with the Pelican that such a story happened by the will of fate. In 1578, Francis Drake changed the name of this ship to "Golden Hind" (in Russian this name sounds like "Golden Hind"). It was under this second that it was inscribed in sparkling golden letters in the world history of seafarers. Francis Drake performed quite a few dizzying deeds on it, which were later told in history and adventure books.

It is such wonderful ships that make many people collect models of ships from wood with their own hands. Drawings of many of these structures can often be found on the Internet. So, inspired by the ancient history of sailing, we will learn from this article information on how to do something like this.

DIY wooden ship model: from the beginning to the rainbow horizons

In fact, the history of modeling consists of several stages. Moreover, each of these stages is associated with several signs. A fan of miniature shipbuilding may need to be able to modify the available materials. It is also important to expand the selection of objects to be modeled. After he has developed enough, then he can have a mass production of models. The next step will be the development of stand exhibition modeling from those sets that he already has. Subsequently, it is possible to develop up to the formation of separate segments. It can be anything - from ship models and in the flesh to copies of individual motorcycles, trucks, as well as all kinds of other cars.

DIY wooden ship models: drawings, instructions, tools

So, well, let's get down to creating such a ship. Carving prefabricated ship models out of wood is not an easy task. You will need a lot of tools for this. Among them are: a knife, a chisel, a hammer, a block (and, if necessary, a saw), thin fabric, superglue, a long wooden spire, a rope, a drill. In addition to this, you will need two more very important parameters. Firstly, it is time, and secondly, an important quality of those people who are engaged in creating prefabricated models of ships from wood is patience.

Carving a ship out of wood

First you have to work with a chisel. You have to file everything plus remove the old bolts that have a flat head. It won't take you so much time - just two minutes. In those two minutes, the pretreated block will later become a boat. Now you need to clean up the block. You should carefully scrape off the bark. Hold the block itself directly towards the instrument. Let's take a standard design as an example for our small ship models, which we will build according to the principle below. Take a pencil and sketch a preliminary sketch on the block. Following this, process the block with a sharp knife. The tilt of the blade itself should be at an angle of about 10 degrees. When planing, keep in mind that this is not the easiest job, so be patient. You should not forget that if for any reason you make a mistake, then it will be quite difficult to fix everything. Remove the shavings layer by layer, while doing your best to process the original block as smoothly as possible. It is important that the top and bottom must be parallel.

Please note that you do not need to throw out the shavings. The fact is that, in principle, it can be used as an additional material as mulch.

Carving of the front part and sides of the ship

Well, now we need to draw the front, bottom, and also the back. We will cut them out in exactly the same way as was mentioned above. It is necessary to make these parts even. In order for you to get the bow of the boat, you will have to saw off a piece from the front. Following this, you must round off the saw cut with a knife. When making the nose, try to tilt the knife blade itself back. It should point towards the stern.

Drilling holes and subsequent installation of equipment

You should have multiple spiers. Therefore, drill a number of holes, they should be slightly larger in size than the beams themselves. It is important that there are not too many holes. Otherwise, you may get a crack. And because of a crack, as you know, a severe disaster can occur - go to leak. Do not use glue! If you do this, then further work will be much more difficult.

Setting sails on the model

Decide, for starters, how many panels you want to get on your final ship. Let's take as a condition that we will have four panels for the first mast and the second, and three for the last. Following this, take a few wooden spiers and cut them off. Cut the fabric in a trapezoid shape. Then start gluing them together. Make notches on the branches of the sails, fasten each branch with the corresponding notch. Then glue the middle of the edges to the sails. Repeat for all masts. It is best if you build the rear mast first, then the middle mast, and then the bow mast.

Now let's set up the upper flying sail. Cut out a fabric kite shape. Take a thread and attach it to the opposite corner of the panel. Leave ends on either side for all corners. Glue a small piece of thread onto the top of the boat. It should be slightly higher than the bow of the boat itself. Measure from the opposite corner down to the middle of the lower sail on the front mast. Then cut the very thread that you measured and glue the tip to the appropriate place.

You should leave some thread on each side. Pull them back and glue them straight into the inside of the boat. Then you can cut off the excess rope. Create and attach the back panel in the same way. It should be attached to the back of the rear sail. Measure, trim, and make sure it fits over the two tabs. Then glue them in the corners.

Well, now you have learned how to make the simplest ship models out of wood. And although this article describes everything only in general terms, we hope that it will help you in your future career as a "shipbuilder". If, of course, you are interested in it. Trust me, it's worthwhile!