The hob allows you to not only cook any dish, but also save space. After all, such equipment has smaller dimensions than large and bulky gas stoves. How to install the hob and oven? Everything is simple. The main thing is to follow the instructions. Everyone is able to cope with such tasks. This does not require expensive equipment, but only the presence of certain tools is important.

What will be required

In conclusion

Now you know how to embed the hob in the countertop with your own hands. Before starting work, it is worth evaluating your skills and abilities. If this is not possible for you, then you should seek the help of professionals. However, it is safe to say that the installation process is not very complicated. Practically everyone can cope with such a task. The main thing is to carefully study the instructions and have all the necessary tools at hand. When performing such work, it is recommended to take into account all the nuances and subtleties of the process.

The layout of modern furniture sets for the kitchen provides for a built-in electric or gas stove, the hob and oven of which are mounted separately. The built-in panel is a functionally finished product, which, in principle, can be used without a kitchen. This article will tell you how to install a built-in hob and connect to the network with your own hands. The surface can be electric, gas or a combination, but the basic rules that should guide the operation are the same for all versions.

Step by step installation instructions

Speaking of tools, if the built-in panel is installed in a new set, and the hole for mounting the case in the countertop has not yet been made, a drill and an electric jigsaw are required. To connect to the mains, you will also need a screwdriver, pliers, a voltage indicator.

The first thing to take care of is a 220 volt electrical outlet, which will include a built-in hob. The choice of its location and installation must be carried out before the installation of furniture. In addition to the panel, the oven is included in the set of the stove. If the first is placed without a cabinet, it can be plugged into one outlet. The electrical socket should be installed lower than the built-in hob will be in order to prevent it from being exposed to moisture and grease during cooking.

When the kitchen walls are completed, you can get to work. You can install the built-in hob according to the following step-by-step instructions:

- First you need to determine the dimensions of the mounting opening, which must be cut in the countertop. This information can be found in the instructions provided by the manufacturer. If there is no instruction, you need to carefully measure the seats. It’s a good idea to make a cardboard layout according to these dimensions (sometimes it is included in the kit), which then needs to be installed on the tabletop and circled with a pencil. It is necessary to provide a gap between the landing parts of the body and the edges of the table from 1 to 2 millimeters.

- Carefully mark the future hole. You will need a long ruler and a pencil. Do not forget that the tabletop is made of pressed sawdust and decorated with artificial stone coating. For this reason, you should not cut a hole closer than 50 mm to the edge, as thin sections of the table may collapse.

- Carefully drill holes in the corners of the marked area with a drill, without going beyond it. We use a drill 8 - 10 mm for this purpose. In the process of drilling, it must be installed and held strictly perpendicular to the surface.

- We insert a wood blade with fine teeth into the electric jigsaw to avoid chipping the surface of the countertop at the border of the slot. Having inserted the canvas into one of the prepared holes, we make a cut according to the markup, firmly pressing the jigsaw to the surface. After cutting, we make sure that the built-in hob fits easily into the seat with a small gap. Otherwise, the edges of the hole should be trimmed.

- It is desirable to protect the end sections of the slot made from moisture. For this purpose, the edges are processed with a sealant, as shown in the photo below. Then you can stick the seal included in the kit.

- Now the built-in hob is being prepared for installation, after which it is installed and connected. Gently insert it into the hole and, with a gentle touch of the hands, push it down until the protruding edges are completely attached to the surface of the countertop. Before this, you can apply a layer of silicone sealant to the surface, which will then be covered by the built-in hob. This will ensure the sealing of the connection. When pressing on the surface, care should be taken, especially if it is glass. It is important that the built-in panel lies evenly on the surface of the countertop. Otherwise, placing a heavy pan on it may create a breaking force.

- The last stage of installation is that the built-in panel is fixed using special fixing clips included in the kit. The clamps are installed from below, after which the case is fixed. Protruding excess sealant that has been applied to the surface of the countertop must be carefully removed. If an oven is installed under the hob, a layer of thermal insulation is laid between them.

The detailed process of installing an electric hob in the countertop is shown in the video tutorials:

Electrical connection

To connect the built-in hob to the mains, it is enough to check the presence of voltage and connect the plug to the socket. When preparing for installation, make sure that the cross section of the wires corresponds to the connected electric power, which the built-in panel has. Otherwise, you need to draw a separate line from the inlet shield to the plate. Then the installation of an outlet may not be required. We talked about it in more detail in a separate article, which we strongly recommend that you read.

Modern kitchen sets allow you to independently install a gas, electric or induction hob. Such models can be operated both in conjunction with the oven, that is, to be dependent, and separately, that is, to be independent. Despite some difference in their design, the general rules that should guide the work are similar for all versions.

Hole preparation

markup

The appearance of the finished kitchen depends on how accurately the markup is carried out, and an error of even half a centimeter will force you to purchase a new countertop.

Markup can be done in two ways:

- put the device in place and circle with a marker;

- Calculate and mark the attachment point to the nearest millimeter.

Despite the apparent simplicity and attractiveness of the first path, there are a lot of chances to make mistakes and apply incorrect markup.

Preliminary sizing

It is much more reliable to mark the installation site by careful calculations:

- On the surface of the countertop, the boundaries of the internal space of the cabinet are applied, above which the hob will be placed. Thus, the place within which the work will be carried out will be indicated. The markings must be applied with a pencil so that at the end of the work the lines can be easily erased. If the countertop does not allow you to draw clearly visible lines, then paper masking tape should be glued to its surface, and markup should be drawn on it.

- It is necessary to find the future center of the hole into which the case will be installed. To do this, diagonals of a rectangle are drawn on the tabletop, formed by the front and back parts of the tabletop and the drawn borders of the cabinet.

- At the intersection point of the applied diagonals, the center of the hob will be placed. Through it you need to draw two straight lines: one parallel to the edge of the countertop, the other perpendicular.

- On these straight lines, the dimensions of the built-in part of the housing should be noted. You can see them in the technical documentation or measure them yourself. These dimensions should be increased by 1-2 mm in order to subsequently install the device more conveniently.

- Straight lines are drawn through the marked marks (parallel and perpendicular to the edge of the tabletop). They form a rectangle, exactly corresponding to the recessed part of the body and located in the center of the tabletop.

- It is necessary to check that the minimum distance specified by the manufacturer in the technical documentation is observed between the final marking lines and surrounding objects.

- The resulting rectangle must be outlined with a marker, and the extra lines must be erased so as not to make a mistake when cutting a hole.

![]()

The marked rectangle corresponds to the size of the hob

Cutting a mounting hole

To cut out the seat for the hob, you can use the following tools:

- milling machine;

- jigsaw;

- drill.

The highest quality cut is obtained when working with a milling machine. A slightly less high-quality cut is made with an electric jigsaw with a fine-toothed file.

![]()

For work, you can use a drill or a jigsaw

The procedure for cutting a hole with a jigsaw is as follows:

- At the corners of the marked rectangle (on the inside), drill holes with an 8-10 mm drill.

- With a file with fine teeth, carefully cut along the marked lines. The body of the jigsaw cannot be held “on weight”, it should be pressed tightly against the countertop.

![]()

The hole is cut along the marked lines

But not every household has convenient tools. Much less beautiful, but, nevertheless, a cut suitable for installation can be made using a conventional drill.

The procedure for cutting the landing hole with a drill is as follows:

- With a drill of 8-10 mm, holes are made along the intended line. They need to be drilled from the inside of the marks so that the drilled places are in contact with the intended cut line. Holes must be made as often as possible so that the cut-off piece of the countertop can be easily broken off.

- The rough edges of the hole must be aligned along the marked line. To do this, you can use a rasp or a small file for wood or metal. The resulting edges must be made as even as possible.

Attention! After the mounting hole has been made, it is necessary to insert the hob into it. The device should enter effortlessly and completely cover the cut hole with its body.

Hole sealing

The next step is sealing. It is necessary to protect the countertop from water ingress during cleaning or cooking. A countertop made of wood or chipboard can swell and deteriorate from this.

Sealing is carried out using acrylic sealant for plumbing or nitro varnish. It must be carefully applied with a thin layer from the inside to the ends of the hole made. It is not necessary to apply sealant to the top surface of the countertop - a special gasket in the form of a sealing tape that comes with the panel will be used there.

![]()

The ends of the countertops are treated with silicone

Sealing tape sticker:

- An adhesive layer covered with a film is applied to the sealing tape. It should not be removed all at once, but torn off gradually, as it sticks to the surface.

- The tape is glued around the perimeter of the mounting hole in a single piece. At the corners, it is not cut, but simply glued with a turn.

- The end and the beginning of the tape are joined end-to-end, without overlap and gap.

Some manufacturers complete hobs with aluminum seals. Instructions for their installation are contained in the documentation for the device.

Panel fixing

Mounting the hob is carried out as follows:

- The appliance is inserted into the mounting hole and centered so that the front side is parallel to the edge of the worktop.

- From inside the cabinet, the case is attached to the tabletop with special plates included in the delivery.

- Installation must be carried out in such a way that there are no gaps between the hob and the worktop.

- With a clerical knife, excess sealant is cut off from above.

![]()

The seal is cut with a clerical knife

Connecting an installed hob

electrical panel

It is advisable to provide a connection point for the electric hob even before installing the kitchen unit. The socket must comply with all electrical safety requirements:

- have a ground line;

- the supply copper cable must have a cross section of at least 4 sq. mm.

A hole is cut in the back wall of the floor cabinet opposite the electrical outlet, so that it is easy to insert and remove the plug from the hob by hand.

Sockets installed for self-connection are of two types:

- three-pin;

- four-pin.

If a plug is installed on the wire of the hob, then it is enough to plug it into the socket to connect it. The power cord must be long enough so that it is not taut when connecting the appliance.

![]()

Plugs and sockets for connecting hobs

For models sold without a plug, certain steps will be required:

- If the socket is three-pin, and there are four wires in the wire, then you will need to connect a two-phase model to a single-phase network. To do this, wires with black and brown insulation are connected in the cord. This connection is connected to the socket phase. The neutral blue wire is connected to the zero of the outlet, and the green-yellow wire is connected to ground. All connections must be securely insulated.

- If the placement of the wires in the outlet is unknown, then using a multimeter, you must determine the phase and zero. If necessary, they are interchanged so that they correspond to the wiring in the plug of the device.

Attention! Self-embedding an electric hob, it is necessary to provide for the mandatory installation of individual RCDs and a circuit breaker. For example, for a 16A socket, an RCD of at least 40A is required, and an automatic device is at least 25A.

induction hob

The induction panel is connected according to the same general principles as the electric one.

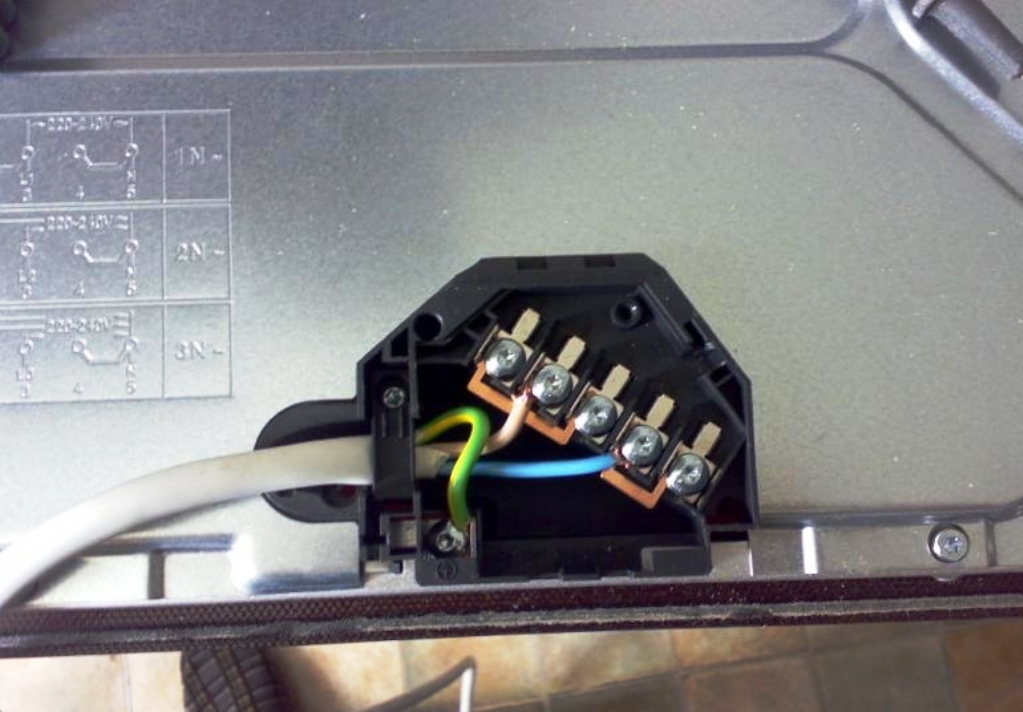

In many models there are no power cords, and only terminals for connecting an external cable are installed.

![]()

The wiring diagram is printed next to the terminal block

Connection in this case is carried out in the following order:

- The protective cover is removed from the back of the instrument.

- The external cable is passed through the cover.

- The cord is connected to the terminal plate in accordance with the diagram attached to the panel.

- If a jumper is installed connecting zero and ground, it must be removed.

gas hob

Household gas is a source of increased danger, therefore, special requirements are imposed on the kitchen room:

- The presence of a ventilation hood.

- Air inflow not less than 2 cubic meters. per hour for each kilowatt of panel power.

- The distance to the wall is at least 130 mm.

- The supply gas hose must be located in such a way that it is not exposed to excessive heat and allows periodic inspection by the inspection body.

![]()

The hob is connected with a flexible hose

Attention! If the mandatory requirements are not met, the operating organization will not allow the operation of the installed gas hob.

The panel is connected by a certified specialist in the following order:

- Sealing fum-tape is applied to the places of threaded connections.

- Paronite gaskets are inserted into the gas hose.

- The hose is connected to the hob and the gas supply.

- The joints are checked for tightness with soap suds.

- The power cord plugs into a waterproof outlet.

For the operation of gas models, they must be accepted by the service organization responsible for these works in the area of residence.

You can embed the hob in the kitchen set on your own, carrying out the work carefully in accordance with the recommendations presented.

An integral attribute of the kitchen is a gas stove, behind which, ideally, a husband stands and prepares breakfast for his wife. Increasingly popular are not classic gas or electric stoves, but hobs. Their convenience lies in their compactness and the possibility of a separate installation of the oven. But their installation on the countertop will make an inexperienced craftsman sweat. Is it possible to fix such a module on my own and what is needed for this? This will be discussed in the article.

Varieties of cooking surfaces

All cooking surfaces can be divided into two large groups. The power source unites these groups, its role can be played by:

- electricity;

In appearance, hobs that are connected to the gas line are practically no different from ordinary stoves. An option for such modules may be an automatic start system, which may be self-contained or dependent on electricity. In the first case, it is represented by a piezoelectric element, which delivers a spark at the right time. Burners on gas surfaces may vary in size for greater ease of use.

Electric hobs can be of two types:

- classical;

- induction.

In a classic hob, the role of a burner is performed by a heating element or another heating element. Such a module is cheaper and does not differ in particular profitability. Induction hobs are the dream of any modern housewife. The essence of the functioning of the product is to heat the product due to the electromagnetic field. At the same time, if you put your hand on a working burner, you will not feel anything. For the normal functioning of the product, a metal pan with a thick bottom is required. In this case, the material from which the dishes are made must necessarily be magnetized. The installation process for each of these surfaces is very similar. The difference lies only in the need to connect the gas hose for the first version of the stove.

Installation Tool

The entire installation process does not take much time and requires a tool that may already be in the arsenal of a home master. The main tools include:

- screwdriver or drill;

- electric jigsaw;

- roulette;

- marker or pencil;

- silicone sealant.

Additionally, you may need a level or a long metal ruler to make it easier to draw straight lines.

Preparatory stage

If we are talking about a hob that is powered by an electrical network, then the preparatory stage will be to supply power. The average power consumption of such modules is within 3.2 kW. This means that a regular but good outlet will suffice for connection. If the outlet was not installed in advance, then you can purchase an overhead version, since it will be easier to mount it and you will not need an additional tool in the form of a puncher or a drill with a crown. The cable for such an outlet must go directly from the switchboard.

This step is taken in order to provide such a powerful device with a separate circuit breaker that would control its operation. The rated current for which the machine must be designed is 16 amperes. The best solution would be to install a differential machine that is able to catch the slightest leaks. The socket is mounted slightly below the countertop. This is done not for greater ease of connection, but so that moisture and fats do not get on it when cooking. The outlet must be grounded in case of a short circuit.

Note! It is worth noting that a standard outlet can withstand a load of 3.5 kW and a current of 16 amperes.

Step-by-step instruction

An important step during the installation of the hob in the countertop is the markup. Usually, the manufacturer in the technical documentation that comes with the hob indicates what the dimensions of the installation hole should be. One option would be to make a cardboard swatch that can be used to draw the outline of the future hole. There is another option, how you can markup, it is visible in the photo below.

It is necessary to place the hob on the countertop, but turn it upside down. She will be a model. It must be located in the place where direct installation will be carried out. The photo clearly shows that it is important to make a small gap from the edge of the countertop to the hob. Usually it is about 5 cm. It is done so that the edge of the cooking surface is not damaged from constant interaction with it.

The next step, as shown in the photo, is to apply the markup. To do this, the hob is simply outlined in a circle with a pencil. The lines must be accurate so that they do not have to be redrawn several times, because this will only confuse them later.

The photo shows that the hob has a small protrusion, thanks to which it is fixed in the hole. This protrusion has a certain size that must be taken into account. It is also important to mark it on the contour of the future hole, as shown in the photo below.

In this case, it is necessary to make a small gap. If the protrusion has a length of 15 mm, then the size of the hob must be deviated from the main line by only 10 mm. A gap of 5 mm is required to ensure that the hob can be easily installed in the prepared hole.

After marking for the hob, it is necessary to prepare holes to make it easier to cut out the necessary part. Holes are drilled with a drill or screwdriver at four corners. In this case, it is necessary to ensure that the drill does not cause damage to the facade or other elements of the kitchen set. The diameter of the drill should be such that the nail file freely enters the hole.

To continue the process of mounting the hob, you will need a jigsaw. His file is inserted into the prepared hole and the cut is made. It is important to remember that it is necessary to cut along the inner, and not along the outer line. If a mistake is made, then the surface will simply fall into the hole without fixation.

In the process of work, it is necessary to remove sawdust in a timely manner so that they do not overlap the cutting line, since you can easily get off it and damage the countertop. During the cut, it is necessary to ensure that the nail file does not damage the walls of the cabinets or their surface. Before going through the last side, it is necessary to provide the tabletop with sufficient support so that the nail file does not bite, and also so that part of the tabletop does not fall on the leg.

After the hole is ready, you can try on the hob to make sure it fits the way you want it to.

The process does not end there. The tabletop is most often made of chipboard. If moisture gets on it, it swells and deforms. When cooking on the hob, this scenario is inevitable, so it is important to protect the place that has lost the laminated layer. To do this, a special sealant is applied to it, which is used when installing panels. It also acts as a fixing basis for the entire structure. The layer should be sufficient to cover all places accessible to moisture.

An adhesive-sealant is applied to the reverse side of the hob rim, which additionally fixes the product on the countertop. After that, the panel is inserted into its place and gently pressed down until contact with the surface of the countertop is felt. The sealant that has come out must be removed immediately, because after drying it will be more difficult to do. It is important to check that the abutment is the same on the entire surface. If this is not done, then under pressure from a heavy pan, the glass may burst.

Advice! If the hob is glass, then it is important to be careful when applying pressure so that it does not burst.

This fixation does not end there. Special metal plates are supplied with the surface, as seen in the photo above. They must be screwed in such a way that they provide a stop and prevent the panel from rising above the worktop. You can watch a video on installing the hob below.

Network connection

Upon completion of the installation process, you can proceed to the connection of the electrical part. Most often, hobs are supplied in a single-phase version, but they can also be three-phase, which will be useful if three phases come to a house or apartment. Usually the hob has a built-in power cable. But if it is not, then you will need to buy it separately. To connect, you need a wire marked PVA 3 × 4. Each strand of this cable is rated for a rated continuous load of 8 kW.

This is necessary for a small margin, which will prevent overheating of the conductor. The wires are stripped from both sides. A plug is mounted on one, which in terms of current strength must correspond to that specified for the hob. If this is not observed, then it can simply melt. The wire is non-monolithic, so you will need to crimp the cores with tips. Near the terminal block, where the connection to the hob will be made, markings are usually applied.

The Latin letter L indicates the cable through which the phase comes, the letter N indicates zero, maybe the third letter E, which indicates the place where the ground wire is connected. Most often, instead of the third letter, a drawing is applied that indicates grounding. It is important to firmly fix each core that is crimped with a lug with a bolt. The service life will depend on the quality of the contact. If an oven will be installed under the hob, then a separate outlet must be provided for it. The total power consumption of the surface and the cabinet is twice that allowed for a single-phase outlet.

Summary

As you can see, the installation of the surface can be done independently without significant skills. During operation, all precautions and safety precautions must be observed. While drilling and working with an electric jigsaw, goggles must be worn in front of your eyes, which will protect you from flying sawdust. During the installation of the socket and the connection of the electrical part, it is necessary to use tools that have dielectric handles that protect against electric shock. Before starting work, it is necessary to de-energize the machine, which is attached to the prepared wire in the kitchen.

Installing the hob in the countertop: 6 steps

You can install the hob yourself if you first read the instructions Many years ago, kitchen sets did not represent the possibility of mounting a hob in them. Today, this is a common phenomenon, which saves space in the kitchen, and also makes cooking more convenient and comfortable. Installing the hob in the countertop can be done independently. The main thing is to correctly determine the sequence of actions and follow it. It is very important to correctly determine the size of the future opening.

Do-it-yourself hob installation

Modern technologies do not stand still. Today it has become possible to integrate hobs into kitchen sets, which qualitatively affects the interior of the kitchen and its functionality. Inserting the hob does not take much time.

You can read more about the features of electric hobs in the article “3 types of hob”.

First of all, on the countertop, you need to make a markup that will fit the size of the hob.

Next to each side of the niche, you need to drill a hole, the diameter of each should be from 8 to 10 mm. The next step is to cut out the niche and treat it internally with silicone. The tabletop is installed on the lower level of the headset. The inside of the panel is attached with double-sided tape or a little plasticine. The tabletop is covered with silicone.

In order to properly install the hob, you should follow the step-by-step instructions

In order to properly install the hob, you should follow the step-by-step instructions

Step by step installation:

- The tabletop is placed on the bottom of the headset. If the walls are uneven, the countertop will need to be trimmed. And if gas pipes pass through it, special holes must be made for them. The countertop should be ready for installation down the kitchen.

- Inside the box in which the hob will be installed, it is necessary to make markings. To do this, you can simply make pencil outlines that will help you make further markup.

- The tabletop is laid face down, and markings are made on the reverse side for a future tie-in.

- In each intended cut, small holes must be made so that you can work with a jigsaw.

- Carefully cut out the niche with an electric jigsaw.

- You need to make sure that the tabletop does not deviate under its own weight. In the process of cutting, it is better to carefully support it.

The inside of the cut is treated with silicone. After installing the panel, you can additionally coat it with silicone from the outside. This is done in order to create an additional hydro-barrier, since the fasteners may not be pressed against the countertop enough.

The gas hob must be chosen very responsibly, because it should last for many years. After the choice is made, the panel must be installed so that it is convenient and safe to use. You can embed the panel yourself, but you should not do this if you are not confident in your abilities. In any case, you can contact a specialist for help.

When installing it yourself, it is important to prepare all the necessary materials: panel, measuring instruments, pencils, sealant, adjustable wrench, saw, gas winding, steel hose.

All work related to gas is unsafe to carry out. It is best to perform the installation together with a wizard or someone who thoroughly knows the entire installation process. One of the most important stages of installation is the choice of hose.

If you need to install a gas hob, it is better to seek help from specialists

If you need to install a gas hob, it is better to seek help from specialists

Hose Selection Tips:

- Check hose for damage. There should not be a single defect on the hose.

- The hose must be certified. When buying, you should ask the seller to present all the documents for the goods.

- The hose can be corrugated metal or rubber.

When installing the panel, the calculation of dimensions must be given special attention. Sometimes in the kit for the hob you can find a template that you need to use in order to properly saw through the countertop. It is important to remember that water should not get on the surface of the panel. The gas countertop must be placed at a safe distance from furniture and textiles.

How to install the hob in the countertop

The built-in electric stove is a very convenient device for installation in the kitchen. It works just as efficiently as a stationary stove, but does not take up as much space. Installing such a panel can be quick and easy, without resorting to the help of specialists. The surface can be combined with an oven, which will make cooking even more convenient.

If the master does not carry out independent repairs for the first time, then installing the hob will not cause difficulties.

Before installing the panel, you need to properly cut a hole in the countertop. To facilitate the installation work, manufacturers indicate the required dimensions in the instructions for the device. Pre-marking greatly simplifies and speeds up the installation process.

Before installing the hob, special markings must be made on the countertop

Before installing the hob, special markings must be made on the countertop

Installation steps:

- On the countertop, you need to make markings that will correspond to the dimensions of the panel.

- Using an electric jigsaw, you need to make a cutout in the countertop. To get started, you need to drill a small hole for a jigsaw. The cut will be even if you use a jigsaw file with fine teeth.

- The dimensions of the hob must match the cut hole. Sections must be treated with a sealant or nitro-lacquer. Sealing self-adhesive tape can be used for processing.

The electric tabletop is connected, focusing on the diagram. It can be found on the back of the panel. It is important to connect the wires correctly in order to be able to control the activation of the burners and their temperature.

What to look for: fixing the hob to the countertop

The installation process of the hob is simple, but requires careful preparation. First of all, it is tedious to choose the right hob, check its passport data, prepare the tools and decide on the installation location. The installation of a gas and electric hob is practically the same.

You need to mount the panel on the countertop, in which you need to make the appropriate cutout.

It should be noted that to install the electrical panel, you will also need to install an electrical outlet. For a gas panel, care must be taken to carry out gas communication. The built-in panel must be installed so that the maximum gap between it and the worktop is 1-2 mm.

When installing the hob, special attention will need to be paid to attaching it to the countertop.

When installing the hob, special attention will need to be paid to attaching it to the countertop.

What to look for:

- Correctly measure the dimensions of the panel and transfer them to the cutout in the countertop.

- Cut out the necessary segment in the countertop in order to perform the installation correctly.

- Treat the countertop with special materials that will protect it from the effects of external negative factors.

- Push the panel into the cutout.

It is important to remember that the mortise panel should not enter the gap with force. If there is a backlash, the location of the countertop must be aligned, focusing on the front edge. Fastening the seal over the entire surface of the countertop will avoid contamination of the panel.

hob seal

The sealing gasket must be attached to the hob. If the panel is removed after some time of use, you will notice that the seal will be covered in dirt and grease. The gasket needs to be replaced from time to time.

If there is a gap between the panel and the countertop, then the plate can be fixed in the plane, but this must be done so that debris does not fall into the vertical gap.

You can buy a special tape, or you can use a glass seal. The table and cutout can be pretreated with a transparent sealant. Sealant residues must be wiped off or carefully removed with a spatula.

Many prefer to use sealing tape because it is safe and environmentally friendly.

Many prefer to use sealing tape because it is safe and environmentally friendly.

Benefits of sealing tape:

- Reliability;

- Ease of use;

- Environmental friendliness.

Bosch seals are known for their high quality. Just placing a panel is not enough. It must be protected from moisture, grease and debris. If the panel is installed in a large opening, and a gap is formed, then the tape and the treatment of the gaps with sealant will help save the situation.

Installing the hob in the countertop (video)

The built-in hob is a convenient device that saves space in the kitchen and provides comfortable cooking. The rules for installing the panel are simple, so you can install it yourself. It is possible to embed a panel qualitatively only when the dimensions of the panel are measured correctly. After cutting a hole in the countertop, it must be well treated with sealant to protect the panel from water and dirt. All actions should be phased and coordinated.

Similar content