Hydroelectric power plants use the power of water to generate electrical energy. Self-made stations solve the problem of remoteness from centralized power grids or help save on electricity.

Advantages and disadvantages of hydroelectric power plants

Hydroelectric power plants have the following advantages over other types of alternative energy sources:

- They do not depend on the weather and time of day (as opposed to). This allows more power to be generated at a predictable rate.

- The power of the source (river or stream) can be adjusted. To do this, it is enough to narrow the channel with a dam or to provide a difference in water heights.

- Hydraulic units do not make any noise (unlike).

- Many types of small power plants do not require any installation permits.

The disadvantages of self-made hydroelectric power plants include the inability to work in cold weather. In addition, the aquatic environment is corrosive, so the parts of the station must be waterproof and durable.

When designing a mini-hydroelectric power station for use as an alternative source of energy for your own home, the following factors should be decisive:

- The proximity of the river to the house. Installing a homemade station away from home is not worth it. The further away the installation, the lower its efficiency, because some of the energy will be lost during transmission. In addition, it is more difficult to protect your hydroelectric power plant from theft or damage.

- Sufficient flow rate or the possibility of its increase. The power of the station increases exponentially with increasing water speed.

Finding out the speed is not difficult. Throw a piece of Styrofoam or a tennis ball into the water and measure the time it takes for it to swim a certain distance. Then divide the meters by the seconds and you get the speed. The minimum sufficient water velocity for a self-made hydroelectric power station is 1 m / s.

If the flow rate of your river or stream is below this value, then it will be strengthened by a small dam or a narrowing pipe. But these options can pose additional challenges. The construction of the dam requires permission from the authorities, as well as the consent of the neighbors.

DIY mini hydroelectric power plant

The design of the hydroelectric power station is quite complex, therefore, it will be possible to independently build only a small station, which will save on electricity or provide energy to a modest economy. Below are two examples of the implementation of a self-made hydroelectric power station.

How to make a mini hydroelectric power station from a bicycle

This HPP option is ideal for cycling trips. It is compact and lightweight, but it can provide energy to a small camp set up on the banks of a stream or river. The resulting electricity is enough for evening lighting and charging mobile devices.

To install the station you will need:

- Bicycle front wheel.

- A bicycle generator that is used to power bicycle lights.

- Homemade blades. They are cut in advance from sheet aluminum. The width of the blades should be between two and four centimeters, and the length should be from the hub of the wheel to its rim. There can be any number of blades, they must be placed at the same distance from each other.

To start such a station, it is enough to immerse the wheel in water. The immersion depth is determined experimentally, from about a third to half of the wheel.

To build a more powerful station for permanent use, more durable materials are needed. Metallic and plastic elements are best suited as they are easier to protect from exposure to the aquatic environment. But wooden parts are also suitable if they are soaked in a special solution and painted with waterproof paint.

The station requires the following elements:

- Steel cable drum (2.2 meters in diameter). The rotor-wheel is made from it. To do this, the drum is cut into pieces and welded again at a distance of 30 centimeters. Blades are made from the remains of the drum (18 pieces). They are welded to a radius at an angle of 45 degrees. To support the entire structure, a frame is made from corners or pipes. The wheel rotates on bearings.

- A chain reducer is installed on the wheel (the transmission ratio should be four). To make it easier to align the axles of the drive and generator, as well as to reduce vibration, rotation is transmitted through the cardan from the old car.

- An induction motor is suitable for the generator. To it should be added another gear reducer with a ratio of about 40. Then for a three-phase generator with 3000 rpm with a total reduction ratio of 160, the number of revolutions will decrease to 20 rpm.

- Place all electricians in a waterproof container.

The raw materials described are easy to find at a landfill or from friends. You can pay specialists for cutting a steel drum with a grinder and for welding (or you can do everything yourself). As a result, a hydroelectric power station with a capacity of up to 5 kW will cost an insignificant amount.

Getting electricity from water is not that difficult. It is more difficult to build an autonomous power supply system based on a self-made hydroelectric power station, to maintain the station in working order and ensure the safety of people and animals around it.

If a river or even a small stream flows near your home, then with the help of a self-made mini hydroelectric power station, you can get free electricity. Perhaps this will not be a very large replenishment of the budget, but the realization that you have your own electricity is much more expensive. Well, if, for example, in a dacha, there is no central power supply, then even small power capacities will simply be needed. And so, to create a self-made hydroelectric power plant, at least two conditions are necessary - the availability of a water resource and a desire.

If a river or even a small stream flows near your home, then with the help of a self-made mini hydroelectric power station, you can get free electricity. Perhaps this will not be a very large replenishment of the budget, but the realization that you have your own electricity is much more expensive. Well, if, for example, in a dacha, there is no central power supply, then even small power capacities will simply be needed. And so, to create a self-made hydroelectric power plant, at least two conditions are necessary - the availability of a water resource and a desire.

If both are present, then the first thing to do is to measure the flow rate of the river. It is very simple to do this - throw a twig into the river and measure the time during which it will swim 10 meters. By dividing meters by seconds, you get the current velocity in m / s. If the speed is less than 1 m / s, then a productive mini hydroelectric power station will not work. In this case, you can try to increase the flow rate by artificially narrowing the channel or by making a small dam if you are dealing with a small stream.

As a guide, you can use the ratio between the flow rate in m / s and the power removed from the propeller shaft in kW (propeller diameter 1 meter). These are experimental data, in reality, the power obtained depends on many factors, but it is suitable for evaluation. So:

- 0.5 m / s - 0.03 kW,

- 0.7 m / s - 0.07 kW,

- 1 m / s - 0.14 kW,

- 1.5 m / s - 0.31 kW,

- 2 m / s - 0.55 kW,

- 2.5 m / s - 0.86 kW,

- 3 m / s -1.24 kW,

- 4 m / s - 2.2 kW, etc.

The power of a self-made mini hydroelectric power station is proportional to the cube of the flow rate. As already mentioned, if the flow rate is insufficient, try to artificially increase it, if it is possible of course.

Types of mini-hydroelectric power plants

There are several basic options for homemade mini hydroelectric power plants.

It is a paddle wheel mounted perpendicular to the surface of the water. The wheel is less than half immersed in the stream. The water presses on the blades and turns the wheel. There are also turbine wheels with special blades optimized for the fluid jet. But these are rather complex structures, rather factory-made than home-made.

It is a vertical axis rotor used to generate electrical energy. A vertical rotor that rotates due to the pressure difference across its blades. The pressure difference is created due to the flow of liquid around complex surfaces. The effect is similar to the lift of hydrofoils or the lift of an airplane wing. This design was patented by Georges Jean-Marie Darier, a French aeronautical engineer in 1931. It is also often used in the construction of wind turbines.

Garland the hydroelectric power station consists of light turbines - hydrowing rotors, strung and rigidly fixed in the form of a garland on a cable thrown across the river. One end of the cable is fixed in the support bearing, the other rotates the rotor of the generator. In this case, the cable plays the role of a kind of shaft, the rotational movement of which is transmitted to the generator. The flow of water rotates the rotors, the rotors rotate the cable.

Also borrowed from the designs of wind power plants, a kind of "underwater wind turbine" with a vertical rotor. Unlike an air propeller, an underwater propeller has a minimum width of blades. For water, a blade width of only 2 cm is sufficient. With this width, there will be minimum resistance and maximum rotation speed. This blade width was chosen for a flow rate of 0.8-2 meters per second. At higher speeds, other dimensions are probably optimal. The propeller does not move due to water pressure, but due to the generation of lift. Just like an airplane wing. The propeller blades move across the flow rather than being carried away by the flow in the direction of the flow.

Advantages and disadvantages of various systems of homemade mini hydroelectric power plants

The disadvantages of the garland hydroelectric power station are obvious: high material consumption, danger to others (long underwater cable, rotors hidden in the water, blocking the river), low efficiency. The Garland Hydroelectric Power Station is a kind of small dam. Suitable for use in deserted, remote locations with appropriate warning signs. May require permission from authorities and environmentalists. The second option is a small stream in your garden.

The Darrieus rotor is difficult to calculate and manufacture. At the beginning of work, you need to untwist it. But it is attractive in that the rotor axis is located vertically and power take-off can be performed above water, without additional gears. Such a rotor will rotate with any change in the direction of flow - this is a plus.

The most common in the construction of self-made hydroelectric power plants were the schemes of the propeller and water wheel. Since these options are relatively easy to manufacture, require minimal calculations and are implemented at minimal cost, have high efficiency, are easy to configure and operate.

An example of the simplest mini-hydroelectric power station

The simplest hydroelectric power plant can be quickly built from a regular bicycle with a bicycle headlight dynamo. Several blades must be prepared from galvanized iron or not thick sheet aluminum (2-3). The blades should be long from the wheel rim to the hub, and 2-4 cm wide. These blades are installed between the spokes in any way you can or pre-prepared fasteners.

If you are using two blades, then set them opposite each other. If you want to add more blades, then divide the circumference of the wheel by the number of blades and install them at equal intervals. You can experiment with the depth of immersion of the paddle wheel in the water. Usually it is submerged from one third to one half.

The option of a marching wind farm was considered earlier.

Such a micro hydroelectric power station does not take up much space and will perfectly serve cycling tourists - the main thing is the presence of a stream or rivulet - which is usually the case in the campsite. A mini hydroelectric power plant from a bicycle will be able to light up a tent and charge cell phones or other gadgets.

To begin with, let's decide on the principle of operation and types of small hydroelectric power plants. The current of the river or the falling water stream rotates the turbine blades and the hydraulic pipeline, which is connected to an electric generator - the latter and generates electricity. Modern compact hydroelectric power plants have automatic control with the ability to instantly switch to manual mode in the event of an emergency. The designs of modern plant hydroelectric power plants allow minimizing the production of construction work during the installation of equipment.

Types of mini hydroelectric power plants

Mini power plants include generating devices with a capacity of 1 to 3000 kW. In principle, the TPP consists of:

- turbines (water intake);

- generating unit;

- control systems.

By the type of water resources used for generation, mini hydroelectric power plants are:

- Channel. Such stations are built on small flat rivers with reservoirs.

- Mountain. Stationary stations that use the energy of a fast mountain current.

- Industrial. Stations using water flow differences in industrial enterprises.

- Mobile. Stations using reinforced sleeves for water flow.

The dam types of stations are very powerful, but the construction of the dam is expensive, and in this case, one cannot do without permits. To communicate with officials in our country is not just to make life difficult for yourself, but to question the implementation of the best intentions, so we will abandon this venture right away.

How the mini hydroelectric power station works

A schematic diagram of the operation of a hydroelectric power station can be selected from several options:

- Garland hydroelectric power station. From one bank of the river to the other, a cable with rotors strung on it is laid under water. The current rotates the rotors and, accordingly, the cable itself. One end of the cable is in the bearing, the other is connected to the generator.

- Propeller. An underwater structure resembling a wind turbine with narrow blades and a vertical rotor. A blade with a width of only 20 mm at high rotational speed will provide minimal resistance. A blade of this width is selected at a flow rate of 0.8–2.0 m per second.

- Water wheel. A paddle wheel partially submerged in the stream and at right angles to the surface of the water. The stream of water presses on the blades, rotating the wheel.

- Rotor Daria. Vertical rotor with complex blade surfaces. The fluid flowing around the blades creates different pressures, due to which rotation occurs.

The photo shows a mini hydroelectric power station based on a water wheel

How to assess the potential capacity of a mini hydroelectric power station

Before building a mini hydroelectric power station, you need to determine the power you can count on with your own hands. There is a reference relationship between the water flow rate and the power that can be removed from the shaft in kW with a propeller diameter of 1 m.

The flow rate is determined by measuring the time it takes for a chip to travel a certain distance when thrown into the water. Having made simple calculations, we get the flow rate in meters per second. If in this case the speed is less than 1 m / s, then the construction of a hydroelectric power station will be economically inexpedient.

At a flow rate of 2.5 m / s, the power will be 0.86 kW, at 3 m / s - 1.24 kW, at 4 m / s - 2.2 kW. The relationship is described by the relationship: the power of the hydroelectric power station is proportional to the cube of the water flow rate. If the flow rate at the site of the proposed construction is low, you can try to increase it with a device for a difference in flow heights or by installing a drain pipe with a variable diameter at the outlet of the reservoir. The smaller the outlet pipe diameter, the higher the flow rate will be.

How to make a mini hydroelectric power station at home

The principle of operation of a small home-made hydroelectric power station can be understood on the example of a bicycle with a headlight and a dynamo (generator).

- From the roofing iron we make three blades with a length equal to the radius of the bicycle wheel (the distance from the central hub to the wheel rim) and 3-4 cm wide.

- We install the blades between the spokes of the wheel, bending the edge of the blade around the spokes for fastening. The blades should be aligned evenly while maintaining the same angles between them.

- We immerse the wheel with blades in a fast river to a depth of one third to half the wheel diameter. The generated electricity will be sufficient, for example, to light up a tent.

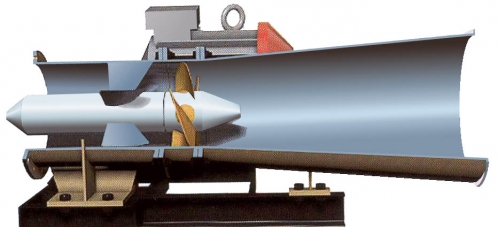

Drawing of one of the options for the construction of a mini hydroelectric power station

An example is a small hydroelectric power plant for a farm with a capacity of 3-5 kW from scrap materials:

- The rotor can be made from an old metal cable drum with a diameter of 2.2 m. Using a grinder and welding at an angle of 45 degrees to the radius, you need to weld 18 blades. The rotor rotates on bearings. Support - metal pipe or corner.

- On the rotor, you need to install a chain reducer with a gear ratio (transmission ratio) 4. Further, the rotation will be transmitted through the cardan shaft VAZ 2101. Using the cardan will reduce vibration, and the alignment of the drive and generator when using the shaft will be uncritical.

- You will need a step-up gear (factor - 40) and a three-phase generator. The generator rotation speed is about 3000 rpm. The total reduction ratio of the two gearboxes is 40 x 4 = 160. The generator should be covered with a cover to protect it from moisture and safety. The design rotation of the water wheel should be about 20 revolutions per minute.

- An asynchronous motor can be adapted for a generator, and the control unit can be taken from any small machine. You will need a VVG NG 2x4 cable length from the rotor to farm buildings.

conclusions

The total manufacturing costs will be about 10-15 thousand rubles. The main item of expenses is the salary of a welder and a worker who helps to make and assemble the structure.

The main advantages of such equipment are low cost of electricity, environmental safety, inexhaustible source of energy and simplicity of design.

Mini hydroelectric power station. Micro hydroelectric power plants

A small hydroelectric power plant or small hydroelectric power plant (SHPP) is a hydroelectric power plant that generates a relatively small amount of electricity and consists of hydropower plants with an installed capacity of 1 to 3000 kW.

Micro hydroelectric power plant is designed to convert the hydraulic energy of the fluid flow into electrical energy for further transmission of the generated electricity to the power system. The term micro means that this hydroelectric power plant is installed on small water bodies - small rivers or even streams, technological channels or elevation changes in water treatment systems, and the power of the hydroelectric unit does not exceed 10 kW.

SHPPs are divided into two classes: these are micro-hydroelectric power plants (up to 200 kW) and mini-hydroelectric power plants (up to 3000 kW). The former are used mainly in households and small enterprises, the latter - in larger facilities. For the owner of a country house or a small business, the former are obviously of greater interest.

Based on the principle of operation, micro-hydroelectric power plants are divided into the following types:

Water wheel ... It is a wheel with blades, mounted perpendicular to the surface of the water and half submerged in it. During operation, the water presses on the blades and forces the wheel to rotate.

In terms of ease of manufacture and maximum efficiency at the lowest cost, this design works well. Therefore, it is often used in practice.

Garland mini-hydroelectric power station ... It is a cable thrown from one river bank to another with rotors rigidly fixed to it. The flow of water rotates the rotors, and from them the rotation is transmitted to the cable, one end of which is connected to the bearing, and the other to the generator shaft.

Disadvantages of a garland hydroelectric power station: high material consumption, danger to others (long underwater cable, rotors hidden in the water, blocking the river), low efficiency.

Rotor Darrieus ... This is a vertical rotor that rotates due to the pressure difference across its blades. The pressure difference is created due to the flow of liquid around complex surfaces. The effect is similar to the lift of hydrofoils or the lift of an airplane wing. In fact, SHPPs of this design are identical to the wind generators of the same name, but are located in a liquid medium.

The Darrieus rotor is difficult to manufacture, at the beginning of work it needs to be untwisted. But it is attractive in that the rotor axis is located vertically and power take-off can be performed above water, without additional gears. Such a rotor will rotate with any change in the direction of flow. Like its aerial counterpart, the efficiency of the Darrieus rotor is inferior to the efficiency of a propeller-type small hydroelectric power station.

Propeller ... This is an underwater "wind turbine" with a vertical rotor, which, unlike an air one, has blades with a minimum width of only 2 cm. This width provides minimum resistance and maximum rotation speed and was chosen for the most common flow rate - 0.8-2 meters per second.

Propeller SHPP , as well as wheeled, are easy to manufacture and have a relatively high efficiency, their frequent use is due to this.

Classification of Mini Hydroelectric Power Plants

Power output classification (field of application) .

The power generated by a micro hydroelectric power station is determined by a combination of two factors, the first is the pressure of water entering the blades of the hydro turbine, which drives the generator that generates electricity, and the second factor is the flow rate, i.e. the volume of water passing through the turbine in 1 second. Consumption is a determining factor when attributing a hydroelectric power station to a certain type.

According to the generated capacity, SHPPs are subdivided into:

- Household power up to 15 kW: used to provide electricity to private households and farms.

- Commercial power up to 180 kW: supply electricity to small businesses.

- Industrial capacities over 180 kW: generate electricity for sale, or energy is transferred to production.

Classification by design

Installation site classification

- High-pressure - more than 60 m;

- Medium-pressure - from 25 m;

- Low-pressure - from 3 to 25 m.

This classification implies that the power plant operates at different speeds, and a number of measures are taken to mechanically stabilize it. the flow rate depends on the head.

Components of Mini HPP

The power generating unit of a small hydroelectric power station consists of a turbine, a generator and an automatic control system. Some of the system elements are similar for or. The main elements of the system:

- Hydraulic turbine with blades, shaft-connected to a generator

- Generator ... Designed to generate alternating current. Connects to the turbine shaft. The parameters of the generated current are relatively unstable, however, nothing similar to power surges during wind generation occurs;

- Hydro turbine control unit provides start and stop of the hydraulic unit, automatic synchronization of the generator when connected to the power system, control of the operating modes of the hydraulic unit, emergency stop.

- Ballast load unit , designed to dissipate the power unused by the consumer at the moment, avoids the failure of the electric generator and the monitoring and control system.

- Charge controller / stabilizer : designed for battery charge control, blade rotation control and voltage conversion.

- Bank AKB : storage tank, the size of which determines the duration of the autonomous operation of the object fed by it.

- Inverter , many hydroelectric systems use inverter systems. With a battery bank and a charge controller, hydraulic systems are not much different from other systems that use renewable energy sources.

Mini hydroelectric power station for a private house

The rise in electricity tariffs and the lack of sufficient capacity make the use of free renewable energy sources in households topical. Compared to other sources of renewable energy sources, mini hydroelectric power plants are of interest, since with equal power with a wind turbine and a solar battery, they are able to produce much more energy in an equal period of time. A natural limitation on their use is the absence of a river

If a small river, stream flows near your house, or there are elevation differences on lake spillways, then you have all the conditions for installing a mini hydroelectric power station. The money spent on its purchase will quickly pay off - you will be provided with cheap electricity at any time of the year, regardless of weather conditions and other external factors.

The main indicator that indicates the efficiency of the use of SHPP is the flow rate of the reservoir. If the speed is less than 1 m / s, then it is necessary to take additional measures to accelerate it, for example, make a bypass channel of variable cross-section or organize an artificial height difference.

Advantages and disadvantages of micro-hydropower

The advantages of a mini hydroelectric power station for home include:

- Environmental safety (with reservations for fry fish) equipment and the absence of the need to flood large areas with colossal material damage;

- Ecological cleanliness of the received energy. There is no influence on the properties and quality of the water. The reservoirs can be used both for fishery activities and as sources of water supply for the population;

- Low cost of the electricity received, which is several times cheaper than that generated at thermal power plants;

- The simplicity and reliability of the equipment used, and the possibility of its operation in an autonomous mode (both within and outside the power supply network). The electric current generated by them meets the requirements of GOST in terms of frequency and voltage;

- Full service life of the station - at least 40 years (at least 5 years before overhaul);

- the inexhaustibility of the resources used to generate energy.

The main disadvantage of micro-hydroelectric power plants is the relative danger to the inhabitants of the aquatic fauna, because rotating turbine blades, especially in high-speed streams, can pose a threat to fish or fry. The limited use of technology can also be considered a conditional disadvantage.

Wind generators are the most common alternative energy sources, but they are highly dependent on weather conditions. In the absence of wind or its weak flow, they turn out to be ineffective. For the normal operation of such generators, areas where the average annual wind speed is at least 5-6 m / s and higher are good.

In Russia, there are not so many regions with intense winds, the steppes and the Black Sea coast of the Kuban, the Far East coast and up to a dozen uninhabited or small territories.

In the middle zone, in the mountains of the Caucasus, Urals, Altai and other regions where there are small but rapid rivers, tributaries, streams, people forget about the possibility of using hydro generators.

It is not rational to refuse to use them, this is a guaranteed source of electricity, because a river with a stable level and flow is much more reliable than a changeable wind.

Power calculation and design selection

In essence, the electrical part of a wind generator device does not differ from a hydro generator, the principle is similar to convert mechanical energy of rotation into electrical energy.

The difference in the driving force of wind or water, the drive devices will fundamentally differ. Instead of a propeller, hydrogenerators use drum-type wheels with blades.

The hydrogenerator by its own, if they grow from the right place, it is not difficult to assemble, in the presence of a wind generator, it remains to design and assemble a hydraulic drive for its rotation.

In such cases, in order for the generator to rotate at the desired speed, it is often necessary to use gearboxes to vary the force and speed of rotation, which depend on the water flow.

It has been calculated that the power of the filling wheel is significantly greater than that of the filling wheel; when the water flow falls on the blades of the driving wheel from above, the filling wheel rotates with the flow from below.

Therefore, based on your conditions, use the design of the filling wheel whenever possible. However, such a wheel also has its drawbacks:

- its rotation is slower

- requires the construction of additional structures

In the photo above, a direct drive filling wheel is used on a homemade disk generator with permanent magnets, the design of which will be discussed below.

In the designs of the drive mechanism, you can use the elements of vehicles:

- disks

- asterisks

- gears

- chains and belts

In some cases, even gearboxes from mopeds and motorcycles are used, blades are welded onto the disks of large tractor wheels.

Alternators and load connection options

Generators can be used for automobiles, buses, preferably low-speed tractors with permanent magnets.

They are more reliable, easier to operate and repair, they do not have brushes.

1. generator G250-G1 2. P362 relay-regulator 3. car battery 4. ammeter 5 and 6 switches 7 fuse 8 load.

Depending on your conditions and capabilities, you can use 24V generators.

1. Generator G-228 2. voltage regulator 11.3702 3. 12V batteries connected in series 4. Ammeter for measuring the charging current 5 and 6 switches 7. load.

In the simplest case, you can use 6CT-75 batteries, but for reliability it is certainly better to put new lithium-ion starter batteries. They are, of course, more expensive, but lighter in weight than lead-acid ones, smaller in size, larger in capacity in A / Ch, their service life is much longer, and surpass lead ones in all respects.

Everyone decides for himself, depending on the purpose of the generator, operating conditions and financial capabilities.

If you are going to use a hydrogenerator to power household electrical appliances powered by an industrial network 220 / 50Hz, you will have to use voltage and current converters.

These devices convert a direct current of a battery of 12 or 24 V into an alternating current with a voltage of 220 V. They are different in power, you need to choose depending on the current what maximum load you are going to use.

They are connected according to the above scheme instead of the load, the simplest low-power converter can be assembled by yourself.

This circuit has been tested over the years, works like a clock, is simple, does not require adjustment. The disadvantage is that it is a low-power 100W.

Use economical 13-15 W fluorescent lamps or 5-10 W LED lamps are quite enough for lighting a private house, garage and even a yard at night. 15 cotton bulbs in terms of brightness shine like an 80W incandescent lamp.

If you need more power to fully operate the power grid, you can buy industrial converters. A large assortment of 12 / 220V is on sale; 24 / 220V; 48 / 220V, power up to 5 kW and more.

The Pulso IMU-800 inverter converts 12V DC to 220V / 50Hz AC. maximum output power 800W. This is quite

enough for lighting, connecting a TV, refrigerator, more powerful inverters will be needed for irons and boilers.

Assembling a homemade generator with magnets

Many people make a hydroelectricity generator with their own hands, using the method of assembling a generator on niodimous magnets. The basis on which the entire structure will be mounted can be taken as the hub of a car wheel with a brake disc.

Factory assembled, reliable and well-balanced, permanent magnet disks are mounted on the rotating part, between which the disk with the rotor windings will be fixed.

The advantage of a permanent magnet generator is that the magnetic field is controlled, this is achieved:

- minimum clearance between rotor and stator

- through a magnetically conducting disk, the lines of force of all magnets are connected to each other

Therefore, the disks of the rotating rotor must be magnetically conductive; with a different material, the power of the generator will be halved. We draw the disks into 12 identical sectors then, evenly along the perimeter of the disk in each sector, glue magnets with a diameter of 25 mm and a thickness of 5 mm with super glue.

The poles of the magnets alternate through one (S-N-S-N….) And so on in a circle. You can increase the number of magnets and windings, there will be more poles, this will allow you to achieve more power at lower speeds.

But in our case, 12 magnets, windings with a wire of 08-1 mm, 100 turns each generate enough power to charge a 12 V starter battery.

A wheel with a diameter of 5 m, rotating at a speed of 150 rpm, produces a current of at least 1A, at 200 rpm the charging currents reach 4A, this is quite enough.

Winding connection diagram

We make the diameter of the disc 30-35 cm, depending on the size of the hub that you have chosen.

In our version, the magnets are round, but it is better to put rectangular 35x25x5mm, more magnetic flux, respectively, more generator power.

In this case, the stator windings are made oval, with the size of the magnets. When installing the stator, the magnets must be aligned with the center of the windings.

The thickness of the stator disk with windings must be the same as the thickness of the disks with magnets. We place the windings on a plywood disk and connect them in series with each other according to the indicated scheme into a star.

After connecting and insulating the contacts, the wires are carefully laid along the inner diameter so that they do not touch the rotating parts of the structure. Then they are poured with epoxy resin. For reliability, you can cover the poured surface with fiberglass, press it down a little, then again abundantly soak the fiberglass on top with epoxy resin.

Such measures exclude mechanical damage to the windings and moisture ingress. After drying, we assemble the generator plates on the hub platform.

Through the holes for fastening, we put the first disc on the long bolts of the rotating disc of the hub, fix the magnets outward with clamping nuts.

The next one is put on the stator disk with the windings and, last of all, the second disk is put on with magnets inside. The discs are fixed with tension nuts so that the gap between them is uniform over the entire plane and is no more than 3mm. After assembly, scroll to check for vibration and wobbling, adjust if necessary.

When assembling a hydrogenerator with your own hands at home, you should understand that direct connection of the generator to the wheel simplifies the design, but such ideal conditions for supplying the water flow to the wheel do not always exist.

In some places, it is necessary to apply torque transmission schemes through a system of additional shafts, gears or belt drives, this reduces power.

For those who do not want to wind, drill and glue a lot, there are very simple options, you can buy a reliable Chinese generator, a manual drive, or rather a foot drive. Such generators are used in cycling simulators, they combine business with pleasure, convenient in emergency situations.

Generators NJB-800-12 are very practical, have a beautiful design, and are compact.

At a rotational speed of 250 rpm, the output power is 500W, at 500 rpm, 800W. 12V.

It is convenient to transport it in the trunk of a car to a camping site; to use water resources, you only need to attach the blades to the wheel.

Everything is fine, but there is one drawback: it costs almost 30 thousand rubles, not everyone can afford it. If you have a suitable water source, modern technologies allow you to independently make a reliable hydro generator, the most important element in this project is your desire. How to make a manual generator on video: