The now widespread open heating system has a number of serious drawbacks. One of them is direct contact with the atmosphere. As a result, a coolant flows through the pipes, in which there is air. Air bubbles can gradually cause corrosion of the metal elements of the heating system, as well as cause the “noise” of the coolant. All this can be avoided by just making a closed heating system of a private house.

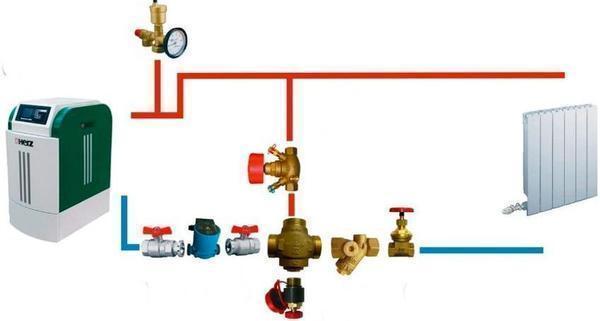

The main feature of such systems (and what an open circuit does not have) is complete isolation from the influence of the environment. The closed heating system, which you can do with your own hands, includes the following elements:

- boiler;

- automatic air valve;

- thermostatic valve;

- heating radiators;

- expansion tank;

- balancing valve;

- ball valve;

- pump and filter;

- manometer;

- safety valve.

How does closed water heating work? If the temperature of the coolant rises, then excess liquid is squeezed into the expansion tank. When the temperature drops, the liquid returns to the system, i.e. pressure is maintained within a fairly narrow range.

For efficient circulation of the coolant, a pump is used (an open system may have natural circulation). True, there is also a minus here - in the absence of electricity supply, a closed system will not be able to function normally (lack of electricity for a country private house is a very urgent problem). But the advantages of using a “pump” more than compensate for the disadvantages - for both an apartment and a private house, installation of additional heating systems is possible. In particular, you can make a warm floor.

The circulation pump is installed on the return pipe ("return") in front of the heating boiler. An expansion tank is also mounted here. Such an arrangement of these important elements allows you to be uncritical about the diameter of the pipes used during installation and the observance of the slope, which open water heating must have.

As a result, less time and materials are spent on the installation of such a heating system (for example, it is no longer necessary to insulate the pipeline, since the expansion tank is installed next to the boiler). However, you should not "abuse" such advantages. This is especially true for the slope (it’s better to do it anyway) - if it is observed, the system will at least work in the event of a power outage, but it will still work, i.e. defrosting does not threaten her.

In the video below you can see a detailed example of the organization of closed-type heating using solid fuel and electric boilers.

The closed heating system is isolated from air penetration. However, its operation does not provide 100% tightness: air can fill the pipes, for example, when adding a coolant to the system. In this case, it will accumulate at the top points. You can get rid of it by means of a Mayevsky crane or float diverters operating on an "automatic". The air already dissolved in the water is removed using special separators installed directly in the pipeline.

Good results in terms of saving heat gives the use of a thermostat. It turns on the main consumer of electricity (pump) only when the temperature in the room drops below a predetermined limit.

How to choose a boiler for closed heating

The scheme of closed heat supply of a private house provides for the use of any type of fuel. It can be gas (the most efficient and profitable option), electricity, diesel or solid fuel.

It is necessary to pay attention to the power of the boiler. The approximate value for an insulated room with ceilings up to 3 meters high is 1 kW per 10 "squares" of a private house.

The figure above is very, very approximate. It all depends on many factors: the material from which the building is built, the quality of the insulation, the presence (absence) of a heated attic or attic. The efficiency of heating is affected by the number of windows and how well they were installed. Therefore, a competent thermal calculation is required, which a qualified engineer can do.

The heating boiler can be single-circuit, double-circuit or with a boiler. As practice shows, mostly country houses have a small area and, consequently, a small need for hot water. From this point of view, the best choice would be a double-circuit boiler (its installation is simple), capable of heating about 10 liters of water to + 30C in half an hour. A boiler with a storage boiler is more comfortable - it constantly “has” ready-made several tens of liters of hot water - constant filling is not required.

Expansion tank for closed type heating

Most often, in the heating system of a private house, water plays the role of a coolant. As the temperature increases, the volume increases and the pressure increases. If a closed heat supply scheme is used, then the pressure can overcome a certain critical value and then the elements of the heating system will be destroyed.

To avoid such a development of events, the installation of a heating system for a private house involves the use of an expansion tank.

Features of the design of the tank of a closed type

Any tank of this type has two main parts: a body made of metal and an elastic membrane inside.

The scheme of its operation is quite simple - air is pumped into the upper half of the tank (in expensive modifications - inert gas), the lower part is filled with water from the pipeline.

When the coolant is heated, the pressure rises, while the membrane “bends”, condensing air or an inert gas. Safety valves are available to prevent dangerous situations. When the pipeline with water cools down, the air pressure on the membrane becomes stronger than the coolant pressure, and it fills the heating system. The expansion tank is installed next to the heating boiler. Membranes are of 2 types.

- Fixed - tightly fixed around the perimeter of the expander. Such devices can be found in the tanks of the heating system of a private house or a small enterprise.

These membranes will last a long time if you follow the recommendations for use. In the event of a rupture, it is impossible to change such a membrane - you will have to change the entire tank;

- Replaceable - they are made in the form of rubber pears, balls that must be filled with water. The installation of such a membrane is carried out on the tank flange. If a rupture occurs, then you can replace the damaged membrane with a new one with your own hands, without involving specialists.

When planning a heating scheme, it is important to first of all calculate the power of the heating boiler, take into account the number of radiators and the length of the pipeline.

Careful planning and calculation of the water heating system, and the installation carried out in accordance with the obtained data, will help you achieve productive, economical and efficient heating.

1.

2.

3.

An open heating system today is in steady demand, but at the same time it has a number of disadvantages that extremely negatively affect the effectiveness of such a design (read: ""). The main disadvantage is contact with the atmosphere: the air in the system contributes to the rapid wear of the pipeline and impairs the performance of the system. It was to avoid this process that a closed-type heating system was developed, which is not affected by the atmosphere.

The principle of operation of closed-type heating

What does a closed-type heating scheme look like? The main design feature that determines the name of such a system is its tightness. A closed-type heating system, the scheme of which includes elements, some of which are used in other types of heating, looks like this:The closed-type heating system is protected from air ingress, but this process cannot be eliminated. For example, when adding liquid to the system, some air can still seep into the pipeline. Air trapped in the pipes will accumulate at the top of the system and form air pockets that will impair system performance and increase the risk of failure.

To release the air that has entered the system, you can use the Mayevsky crane or float diverters that work automatically. If air is dissolved in water, then it can be removed using separators that are installed directly in the pipeline.

To save heat, the closed type heating system uses a thermostat that automatically turns the pump on and off when the room temperature changes.

Choosing a boiler for a closed heating system

A closed heating system in a private house is able to work with any type of fuel: you can use gas devices, electricity, and solid fuels. The choice of a suitable boiler should first of all be influenced by the results of calculations of the required heat output. You can entrust the calculations to a specialist, or you can do it yourself - but in this case the result will be approximate.

There are different types of heating boilers: single-circuit, double-circuit or with a boiler. In country houses, double-circuit boilers are often installed, since their efficiency in small areas is quite sufficient. A boiler equipped with a boiler is a little more convenient: it always has hot water, and it does not need to be constantly filled.

Choice of expansion tank for closed heating

The heat carrier in the heating systems of private houses is usually ordinary water. When heated, water tends to expand, thereby increasing the pressure in the system. If the pressure in a sealed system exceeds the critical point, a pipeline burst may occur. How to make a closed heating system that will not damage pipes?To solve this problem, expansion tanks were created that allow you to eliminate excess fluid, thereby preventing pressure build-up.

The expansion tank consists of two parts: a metal body and an elastic diaphragm, which is located inside and divides the body into two halves. The "rear" part of the tank is filled with air or gas, and the expanded liquid enters the lower part. As the temperature rises, the water continues to expand, affecting the membrane, which begins to shrink.

In case the pressure in the system still turns out to be critically high, there are safety valves (read also: ""). When the liquid cools, the diaphragm begins to expand, filling the closed-type heating system with water by displacing it from the tank.

The expansion tank is usually installed near the boiler.

Membranes in tanks can be of two types:

- fixed. Such a membrane is fixed around the perimeter of the expander and ensures stable operation, but if it is damaged, it will be necessary to change the entire tank.

- Replaceable. Membranes of this type are usually produced in the form of bulky rubber products that are filled with water. Replaceable membranes are installed on the tank flange, and in case of their rupture, you can replace them yourself.

The heating system is an important element of the house, and its calculation must be carried out in accordance with all the rules. The question of which is better: a do-it-yourself closed heating system or one built by professionals remains open, but it is not the most important.

It is very important to choose the right elements of the system, which will provide maximum efficiency and economy, will be reliable and of high quality. A closed heating system, the diagram of which is shown in the photo, can be an excellent choice that ensures that all requirements are met.

If everything was done correctly, then the closed heating system will heat the building for many years, creating a cozy and comfortable environment.

In the private sector within the city or outside it, there is no possibility of connecting the house to central heating, so the owners of cottages are engaged in the installation of autonomous heating. Installation of open and closed heating systems is possible

Autonomous heating is a system of interconnected elements that heat up when connected to a heat source. It can be both stove and water or electric heating - it all depends on whether the residents are there permanently or come periodically.

Properly installed water heating can be powered by any source of energy - gas, solid fuel, mining.

The heat supply of the closed type consists of pipes, a boiler, a circulation pump, a battery and an expansion tank. All elements are sealed - water does not evaporate during heating and circulation.

Differences between closed and open heating systems:

- An open autonomous heating system provides for the installation of an expansion tank in the highest place - in the attic under the roof, in a closed one it can be placed anywhere.

- Unlike an open heating system, a closed heating system is hermetically sealed and isolated from air currents.

- An open heating system uses wide pipes that are installed at a certain slope for better circulation. For a closed system, pipes of smaller diameter are needed.

- For a closed heating system, it is important to properly install and adjust the pump.

Circulation pumps ensure uniform distribution of the coolant through the pipes, increase the productivity of the system and help save fuel consumption.

Closed heating system: advantages and disadvantages

Hermetic heating system with a pump operates under pressure and in full atmospheric isolation, which leads to less oxidation of metal elements.

System advantages:

- The coolant is water, it does not evaporate, it is constantly in the system. If necessary, antifreeze can be used, which allows the system not to freeze, even if it is turned off for a short time.

- The use of a circulation pump allows the system to work faster and, accordingly, heat the room faster.

- The expansion tank can be placed in close proximity to the boiler, which makes the system more compact.

- With the help of special taps, you can adjust the temperature in the room or disconnect one or another room from the system if not needed.

- When installing the system, pipes of small diameter are taken.

- The tightness of the system eliminates the appearance of air pockets in the radiators.

Among the minuses is the fact that the system will not be able to function without electricity. When the power supply is turned off, the pump will stop working.

The only solution to the problem of power outage may be the installation of an autonomous generator, but this is an additional source of costs.

If the pipes of the system are installed incorrectly, which will cause a violation of its operation. Therefore, after installing all the elements of the heating system, it is very important to check it for leaks.

Closed heating system: single-pipe scheme

You can assemble a closed heating system with your own hands, having decided which scheme - one-pipe or two-pipe, will be used during installation.

The single-pipe heating system is closed and is considered optimal for small cottages.

All heating devices - radiators, are interconnected in turn. When installing the system, you need to use a powerful pump that will help the coolant get to the end point of the system faster.

The expansion tank performs a number of important functions in the system. About what it is for and how to choose it correctly, you can read on

In this system, it is not possible to install coolant return risers. During use, it is impossible to regulate the supply of heat in certain rooms; if the temperature in one room decreases, the temperature throughout the house will decrease.

In multi-storey buildings, it is best to use a vertical one-pipe system, while the connection is made from the highest point. It is not recommended to connect more than 10 heaters in a riser. As a rule, on the 1st floor, the batteries heat up weaker than on the last one.

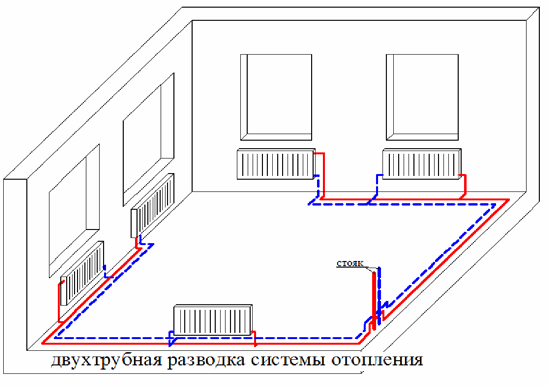

What is a two-pipe closed heating system

In a closed-type two-pipe heat supply system, the carrier (water, antifreeze) goes up the riser and is connected directly to a separate radiator. The heating system is characterized by high performance - water is distributed through the batteries with the same temperature, then goes down the riser back to the heating boiler.

For a private house, a two-pipe horizontal wiring of the heating system is used.

With this heating scheme, it is possible to regulate the flow and temperature on each radiator by installing a thermostat on the battery. All other batteries will not be affected by the disconnection of one cell. Experts recommend installing for each radiator to be installed to expel excess air when starting the system before the heating season.

In a closed-type two-pipe heating system, there is no need to install a hydraulic pump - the coolant is distributed through the pipes on its own.

When choosing between two heating schemes, it must be borne in mind that for all the efficiency of a two-pipe scheme, it requires 2 times more materials - pipes and fasteners.

Types of closed heating system of a private house (video)

A closed-type heating system has many advantages, hence its popularity. With the correct installation of the system elements and the subsequent operation of the heating, the owner will not need to intervene in the work for a long time. It is important to periodically clean the expansion tank and air outlet to avoid malfunctions.

The heating system of a private house is a sequence of elements connected by pipes through which the coolant circulates. The temperature is usually unstable, it is either higher or lower. Together with the temperature, the volume of the coolant increases / decreases, since, like any liquid, it expands when heated, increasing in volume, and contracts when cooled. To prevent pipes or radiators from bursting during heating, a special device is installed - an expansion tank, into which excess coolant is displaced at high temperature. From it, when the temperature drops, it gets back into the system. In this way, a stable pressure in the heating circuit is maintained (within certain limits). The tank can be open or buried, respectively, and the system is then called open or closed.

Open and closed heating system

If an open type expansion tank is installed, then the system is called open. In the simplest version, it is some kind of container (pan, small plastic barrel, etc.) to which the following elements are connected:

Today, open systems are being made less and less, and all because a large amount of oxygen is constantly present in it, which is an active oxidizing agent and accelerates corrosion processes. When using this type, heat exchangers fail many times faster, pipes, pumps and other elements are destroyed. In addition, due to evaporation, it is necessary to constantly monitor the level of the coolant and periodically add it. Another drawback is that it is not recommended to use antifreezes in open systems - due to the fact that they evaporate, that is, they harm the environment, and also change their composition (concentration increases). Therefore, closed systems are becoming more and more popular - they exclude the supply of oxygen, and the oxidation of elements occurs many times slower, because it is believed that they are better.

In closed systems, membrane-type tanks are installed. In them, the sealed container is divided into two parts by an elastic membrane. At the bottom is the coolant, and the upper part is filled with gas - ordinary air or nitrogen. When the pressure is low, the tank is either empty or contains a small amount of liquid. With increasing pressure, an increasing amount of coolant is forced into it, which compresses the gas contained in the upper part. So that when the threshold value is exceeded, the device does not break, an air valve is installed in the upper part of the tank, which operates at a certain pressure, releasing part of the gas, and equalizes the pressure.

Advantages and disadvantages

In addition to the fact that oxidation in a closed system is slower, they have several other advantages:

- the coolant does not evaporate, there is no contact with the external environment, which allows the use of not only water, but also special compounds that increase the efficiency of heating and improve its characteristics;

- higher pressure and circulation rate of the coolant, therefore - its silent movement through the pipes.

With proper organization of heating, the difference between the return and supply temperatures is small, which has a positive effect on the duration of the boiler's operation (an exception is, but there is a different principle of operation).

One-pipe open circuit - the expansion tank is installed at the top point

There are few disadvantages:

- effective operation requires active movement of the coolant, which is achieved either by installing a pump or by creating natural circulation with sufficient slopes;

- with a large volume of the system, a large tank is required, a place for which is not easy to find (its volume should be 10% of the volume of the coolant).

Closed system health monitoring

The main indicator of performance is pressure. It is controlled by manometers. For individual closed-type heating systems with forced circulation, the working pressure is 1.5-2 atm. Moreover, it is desirable to embed pressure gauges at key points through three-way valves, which make it possible to remove the device for repair / replacement, blow through or reset to zero.

If the system is large and powerful, then there are many control points (pressure gauges):

- on both sides of the boiler;

- before and after the circulation pump;

- when using heating regulators - before and after them;

- it is desirable to install before and after mud collectors and filters to control the degree of their clogging.

According to the readings of pressure gauges at these points, it is possible to control the performance of the entire system.

What to do if the pressure drops/increases in the system

If you find a decrease in pressure, the first step is to turn off the pump. And then act on the basis of the readings of the pressure gauge:

- If the static pressure also drops, there is a leak somewhere. You need to inspect all the elements and eliminate it. Please note that even a very small hole (less than a millimeter) can be the cause, so finding damage can be difficult. With a large length of the pipeline, it is possible to localize the leak area: turn off the branches one by one. As soon as the fall stopped, the site was determined - depressurization on the one that had just been turned off.

- If the pressure is stable when the pump is turned off, the pump is out of order, it must be carried in for repair or replaced.

An increase in pressure is less common, but it also happens. It is usually caused by an increase in temperature in the system, and it rises due to insufficient circulation of the coolant. But why the coolant circulates poorly needs to be dealt with.

- First, we check the performance of the pump. Turn off and watch. If the pressure continues to rise, it's not the pump. If it stabilizes, it's his fault.

- We clean the filters and mudguards.

- If the pressure continues to rise, an air lock may have formed - we bleed the air in the system.

- If this did not help, we check the condition of the shut-off valves - maybe someone accidentally or intentionally closed it, blocking the coolant flow.

- Another reason - due to a breakdown or failure of automation, the system is under constant replenishment.

Using this algorithm, you can independently determine the cause of the abnormal state of the heating system and eliminate it.

How to deflate

Now a little about how to bleed air in a closed system. It all depends on the type of wiring. If the wiring is lower, Mayevsky taps are installed on each radiator. Through them, air is released in each battery. To do this, use a special key or screwdriver to turn the lock located in the center. If there is air, a hiss is heard, and if water flows, it is not in an even stream, but as carbonated. When the air is released, the trickle flows smoothly. So bypass all the radiators in a circle several times. Since with the lower wiring, the tops of the radiators are practically the highest points of the entire system, all the air accumulates in them.

To bleed air from the system, a Mayevsky crane is installed on the radiators

If the system has a bypass network (for example, above the door), the high points are above the level of the batteries and the boiler. Then a bleed valve is installed in the circuit, through which air is automatically removed.

With the upper wiring, similar drain valves are placed at the upper points of supply. They also work in automatic mode, preventing blockage of the flow. In many modern boilers, the same valves are in the built-in safety groups. If there is no such device, pumps with deaerators are installed. Even if there is a valve in the boiler, when designing the system, it is better to provide for their installation at the highest points: the costs are small, and operation becomes easier.

Bleed valve - automatically removes air

How to create pressure in a closed heating system

For the rapid movement of the coolant through the pipes, a certain pressure is required. Its value is determined by the type of system - for natural circulation, the pressure should only be slightly higher than atmospheric pressure, and this will be enough, and for forced circulation, its maximum value is required, but not exceeding 2 Bar.

Gravity-flowing single-pipe system with vertical wiring for two wings (circuits). Requires slope to function properly

To create the necessary pressure drop in it is necessary to observe a slope of 1 cm per 1 meter of pipeline length. On the supply line, the slope goes down from the boiler. On the return line, on the contrary, the pipes go down to the boiler with the same height difference. When using pipes of insufficient diameter, this value may not be enough, then the slope can be increased to 5% (5 cm per meter of pipe). In general, for a normal gravity system, careful selection of pipe diameters and slope is necessary - only then will it work normally.

The scheme with the EC requires the mandatory installation of a safety group, which includes a pressure gauge and a blast valve set to working pressure. As the pressure rises, the valve will open, preventing the weakest element from rupturing. Such a situation can happen when using a boiler without automatic control, in particular a solid fuel one, which either gets very hot or almost fades. This group also helps out in case of automation failures.

Types of circuits for closed heating systems

The main advantage of natural circulation schemes is their independence from the availability of electricity, but they have a limitation: the length of the circuit must be no more than 30 meters, otherwise the system will be inoperable. There is one more nuance - with natural circulation, even in a closed system, you need to put a drain valve at the top point, with which you can remove the air that got in, for example, when adding a coolant.

System with natural circulation of a one-story house. Single-pipe scheme, wiring - top

In the scheme with pressure is created by the circulation pump. Some boilers have it built in, some don't. Some long circuits require the installation of two pumps. Then it is not necessary to observe slopes, the most important thing is not to make the sections slope in the other direction, which will negatively affect the performance of the heating and may even require alteration.

On the one hand, the use of circulation pumps is a disadvantage, since its performance depends on the availability of electricity, and on the other hand, it is a big plus:

- allows the use of pipes of a smaller cross section and radiators of a smaller volume, which means less money spent on the purchase of materials;

- to increase the speed of movement of the coolant, which means to reduce its inertia and increase the level of comfort;

- less coolant, less fuel is spent on heating it - money is saved.

Reduced volumes of pipes and radiators mean a reduction in the volume of the system, which again allows to reduce the inertia of heating the coolant - it heats up faster, and heating is more efficient. A smaller volume of coolant means a smaller volume of the expansion tank, and there is no need to look for a place to install it. Modern boilers have built-in membrane tanks (for example,), and the heating efficiency with their use is very high due to the fact that a powerful pump is installed (it is also built-in).

It is better to connect the pump with a bypass - so that it can be repaired / replaced without destroying the system

When choosing a pump, remember that there is a direct relationship between its power and heating efficiency. Therefore, choose low-noise, powerful and reliable.

It is worth noting that it is easy to make a closed system from an open system - you just need to change the expansion tank - put a membrane type and the system will already be operational. For greater efficiency, you will need to embed the pump. Moreover, modern pumps can be installed both in supply and return. Previously, they put it on the return line because the temperatures of the coolant are lower there. But in modern pumps heat-resistant materials are used, for them the temperatures of heating systems are not so critical. Just when buying, pay attention to the operating temperature range, well, or put it in the return line - only so that it “presses” into the boiler. In this case, the pump power can be small, since larger pipe diameters are used in open systems than in closed ones, and the hydraulic resistance of the system is small.

Results

There are many nuances and features in heating a private house, and it is not easy to figure it out. But having set a goal, you can do everything yourself - create a workable good project, choose the right equipment and mount everything yourself. And closed systems in this sense are no exception.

The water heating system, which uses a membrane expansion tank and the coolant does not come into contact with atmospheric air in any way, is considered closed and operates under pressure. This scheme is the most common at the moment, because it has many advantages. In this article, we will analyze what a closed heating system of a private house is, its pros and cons, as well as service features.

What is a closed heating system?

An important feature of such a system is the absence of contact with outside air and the presence of a slight overpressure. As a rule, the circuit works with artificial stimulation of the circulation of the coolant using a pump. This allows you not to worry about observing large slopes of highways, as well as to accept smaller pipe diameters and lay them in the most convenient way.

As a rule, a gravity heating system with natural circulation of the coolant is made with an open expansion tank installed at the highest point. A closed system is traditionally equipped with a circulation pump, which increases its efficiency and reduces material consumption.

Due to their features, closed-type systems have a lot of advantages:

- pressurized coolant heats up faster;

- the probability of airing the network of pipelines and radiators is very low;

- the coolant is not saturated with oxygen and does not evaporate into the atmosphere, which is very important when filling the system with antifreeze;

- installation of an expansion tank in a closed heating system is carried out on the return pipeline near the boiler, which is very convenient in terms of maintenance;

- there is no need to use pipelines of large diameters and lay them in plain sight; in this respect, a closed system with forced circulation is the best choice for a private house.

There is only one significant drawback - dependence on the reliability of power supply, a closed heating system without a pump powered by the mains will not work. Fortunately, circulation units for individual systems have a small power consumption, and therefore, during a power outage, they will be able to operate from an uninterruptible power supply for quite a long time.

Some experts argue that a closed system with natural circulation will help solve the problem of power outage. Recall that in this case the movement of the coolant occurs due to the difference in density and mass of hot and chilled water. The first, heating up in the boiler, as a lighter one, is displaced upwards by the cooled coolant coming from the radiators, which has a large mass.

Despite the fact that the pressure in a closed heating system (1.5-2 Bar) does not prevent the gravitational movement of hot and cold water flows, its efficiency is very doubtful. The fact is that the difference in convective forces is already small, and here you still need to overcome the resistance of the tank membrane, which stretches when the water expands. In order not to mess with these slippery moments, it is better to always put a pump on a closed system. If there is a need to mount a gravity circuit, then it must be made open.

Scheme of a closed heating system

In private housing construction, 2 types of schemes are traditionally used:

- single-pipe;

- two-pipe.

Single-pipe, better known as Leningradka, works satisfactorily in one- and two-story houses of a small area, when no more than 5 radiators are installed on each floor. The implementation of the scheme requires an accurate calculation of the pipe diameters and the number of battery sections, since the coolant cools down significantly after passing through each subsequent radiator. These requirements also need to be met by a single-pipe scheme of a closed-type heating system with an upper wiring, which is shown in the figure below:

Note. Regardless of the type of scheme chosen, a closed system must contain a security group, sometimes it comes with a boiler. The group consists of a manometer for pressure control, an air vent and a safety valve for emergency water release. The unit is installed on the supply pipeline leaving the boiler, and without any shut-off valves.

The two-pipe scheme of a closed system is easier to calculate and install, and is famous for its good performance. After all, the coolant is delivered to all radiators with the same temperature, and when implementing a passing scheme, it also travels the same distance. An example of a two-pipe system is shown in the figure:

Some additions have a closed heating system with a solid fuel boiler. To avoid the formation of condensate in the furnace of the heat generator, the circuit is supplemented with a mixing unit with a three-way valve and a bypass line. The valve makes the water turn around bypass until it heats up to the set temperature, and only then it starts the coolant from the main into the boiler.

How to fill the system with coolant?

When the make-up connection is connected to the water supply network by means of a ball valve, it is quite simple to fill the closed-type heating system with a coolant. For this case, it makes sense to attract an assistant, especially if the house has several floors. One person operates the make-up valve, and the second is responsible for the release of air from the batteries. The faucet opens about a third so that the pressure is not strong.

The person in the boiler room monitors the readings of the pressure gauge, the recharge of the closed heating system is closed when the pressure reaches 2 bar. Now the assistant bleeds air from the radiators by means of Maevsky's taps, after which the pressure drops. The goal is to reach the design pressure by removing all air from the pipelines by gradually replacing it with tap water.

It is more difficult to pump the coolant into a closed system when there is no make-up from the water supply or it is necessary to fill in an antifreeze liquid. To do this, you will need a special manual or electric pump and a container for the coolant, from which it will be pumped into the system. First you need to open all the air valves on the radiators, and then fill the pipes through the drain fitting by connecting a pump with a check valve to it.

As the liquid is pumped in, it is necessary to close the Mayevsky taps, from which the coolant will flow. Having pumped up the system to 1.5 bar, it is necessary to remove the air, after which the pressure is brought to the working one. At the end, a trial run of the boiler and pressure adjustment are carried out, and, if necessary, air is bled.

Why does pressure drop in a closed heating system?

There is only one reason why the pressure drops - the lack of tightness, that is, leakage. The question is to find it. A characteristic sign of a leak is a puddle in a certain place or a brown spot when the water has time to dry. During the search, you should inspect the following nodes and elements:

- pipe connections and fittings: it happens that cracks occur in the latter;

- automatic air vents: a defective element with a stuck float will let water through;

- shut-off and control valves, safety valve;

- expansion tank: a crack in the membrane will cause a pressure drop, air in the system and frequent shutdowns of the boiler.

To eliminate leakage, one cannot do without partial or complete emptying of pipelines. At the end of the work, you will have to pour water into the system again, create the necessary pressure and follow the pressure gauge for several days.

Conclusion

A closed heating system has a lot of advantages, hence its popularity. If the installation and commissioning is carried out correctly, then it does not require intervention in its work for a long time. Most of the malfunctions that occur can be easily fixed with your own hands, as well as system maintenance. It is advisable to check the performance of elements such as air vents, valves and an expansion tank annually.