barn on suburban area- a thing absolutely necessary, and better not even one or two. A person puts a huge number of functions in a barn, ranging from a banal warehouse of garden tools or a poultry house with a grain warehouse, and ending with a temporary (guest) house with summer kitchen and shower.

Location selection

We choose a high place to avoid spring flooding and the formation of puddles during prolonged rains. It is desirable that the selected site is located in a sunny place, and also does not interfere with gardening and possible redevelopment on the site.

Builders of the house in Constantian - houses, witnesses of history

Kitchen and bathroom, one bedroom and one bedroom. A wooden fire was added to the cabin and connected to the garage building, creating a more architectural complex that would fill the entire building. The boiler has switched over to the feeder. As long as we are burning wood, so this function is not needed, but as soon as we change the fuel, we will not be able to facilitate the maintenance of the boiler. There is a place for kiosks, which are replaced by hoarders.

Temporary home, but not alone

This is the end of life for future generations as well. One of the changes to the original design was the elimination of garages in building block. The garage only had one car, so it was too small. Instead we have gym for exercise, but in the garden we will build additional light.

Having decided on the place, we level it and clear it of vegetation. We estimate the dimensions of the future building. Reality does not always coincide with desire, so it is better not to plan the dimensions of the building in advance.

Design nuances

Having precisely decided on the size and functions of the future barn, consider a work plan. Draw a very detailed drawing, diagram (preferably with family members to avoid conflicts in the future). Accompany the entire drawing process with notes For example: rough floor - unedged board 3000 x 250 x 40 mm 10 pcs (3 pcs available), 0.5 kg of nails 100 mm (available), 1 liter of biosecurity, ax (available), hammer (available) , electric jigsaw (available), wood saws 2 pcs, brush 50 mm). Bringing together all your records, you will receive full list tools and materials that you need to buy, as well as what you already have and what you don’t need to buy. And the store will have to go only five times instead of twenty.

We have added light for the instruments and sports equipment and from the back of the building we planned a terrace. After a long consultation with professionals, we decided to build log house. Wood technology gave us construction speed and low cost and the fact that this building can be easily expanded in the future.

Cars, need to solve the problem of parking. Ideally, the party front should be used by both the household and potential clients. The elegant frame will provide a spacious, lightweight globe that can be used at the same time to cover most of the details.

The fastest and cheapest option. The barn is suitable for storing agricultural equipment, firewood, coal, as a simple poultry house, a corral for goats, sheep. In the instructions I will give my measurements, but in similar type buildings dimensions are easily adjusted to your requirements.

The fastest and cheapest option. The barn is suitable for storing agricultural equipment, firewood, coal, as a simple poultry house, a corral for goats, sheep. In the instructions I will give my measurements, but in similar type buildings dimensions are easily adjusted to your requirements.

gardening tools

The house is adjacent to the car with wooden panel and toolbar. The farm is small and no longer has a gardening tool, the house has no basement, and the place of the garage is occupied by the world, you have to ask yourself: where to hide gardening Tools, which we will definitely “discharge”, years? There are several places for such a garden.

However, Robert had to refuse - wood protection was done manually and in stages. During the construction of the house, several balls of the ball and balls of the earth were painted several times. The real impregnation began just a few months later. They both remember it very well.

We level and clean the site. We mark the corners of the future barn. We take four beams 150 x 150 (logs) of 3 meters. We dig holes in the corners, the front ones are 60-70 cm deep, the rear 90-100 cm deep (I personally prefer to drill out). We carefully process the bars with bioprotection at least 2 times.

Used engine oil is perfect for these purposes.

That part of the column that will be buried in the ground, before instillation, it is desirable to cover with molten tar. We install the pillars in the pits, align them vertically, fill the voids with small gravel (crushed construction waste) and fill it with liquid cement mortar.

We make three "rings" of strapping:

- Lower: if the floor is not planned, then a thick board (40 mm) will fit on the poles from the outside (5 cm from the ground). If a floor is planned, then from a beam between the pillars, slightly raising it above the ground, and on the outside of the beam a board, as in the case without a floor.

- Upper: along the top of the short support pillars (we additionally connect two high pillars with the same board). Board 40 mm overlap on the outside. After the top trim, decide where the door will be, and fix two thin bars (40 x 40) on the sides of the future doorway (attach to the split between the top and bottom trim).

- Central: held in the center between the top and bottom, without blocking the doorway, it is attached to the door bars end-to-end. The doorway at the desired height is wedged with a piece of bar 40 x 40.

Roof

We fasten the rafters between the high and low side of the shed, it is better - going deep into the upper trim and making a release of 20-25 cm, we fill the crate or OSB on the rafters - 10 mm oriented strand board. We attach to the crate profile iron, special press washers with a drill. There is no point in saving here. The slate is heavy. Roofing material is one-, two-season coating, and the simplest iron is not so expensive.

We fasten the rafters between the high and low side of the shed, it is better - going deep into the upper trim and making a release of 20-25 cm, we fill the crate or OSB on the rafters - 10 mm oriented strand board. We attach to the crate profile iron, special press washers with a drill. There is no point in saving here. The slate is heavy. Roofing material is one-, two-season coating, and the simplest iron is not so expensive.

Floor

You can remove the upper fertile layer and concrete it (filling it with construction debris) or simply leave it earthen. If you decide to make a regular floor, then we attach logs to the lower trim (timber) and lay on them the material that we decided to use. I recommend 18mm OSB - water resistant by definition.

Walls

We sew up the board vertically, it is better to overlap. At the corners, the last board should be with a straight end. It is nailed flush with the strapping, and another wall begins from it. This will help avoid cracks in the corners. If the barn is without a floor or with a concrete floor, then we nail the boards so that they do not reach the ground a little, and close the gap with a horizontal board from the inside (which can then be simply replaced), outside with boards we close the gaps diagonally between the wall and the roof.

We hang the door. If the shed is planned for poultry or livestock, then it is better to overlap and seal the gaps. If necessary, cut through the windows.

A convenient place under the roof on the front wall of the barn, then the walls will remain free for shelves, hooks, and the animals will not get it.

Do not forget to process all the details with biosecurity. For wall boards interesting solution- remove wane from them and burn them blowtorch and then cover with drying oil. Looks nice and will last a long time.

We equip the barn inside to suit your needs. If you keep living creatures (not exotic), do not forget that adult animals tolerate colds down to -20-25 degrees calmly, but drafts are “evil”. So carefully caulk all the cracks and make a hood.

The first is the foundation. What is the basis, you ask, because we are talking about a building without a foundation? I do not argue, you can assemble a barn right on the ground, without any foundation, but this is an extremely short-lived building and wasted time and effort. Therefore, I propose an option how not to mess with the foundation, but at the same time increase the life of the barn, and also make it mobile.

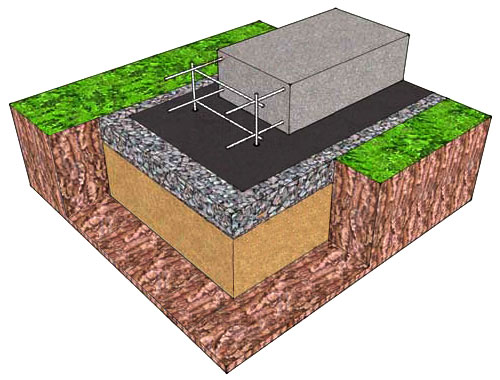

We assemble a barn on ready-made FBS blocks (solid foundation block) 600 x 300 x 200. We dig a shallow hole 25-40 cm, the hole should be a little more than the side of the block on which it will lie (usually 600 x 300). At the bottom of the hole is about ¼ sand. We compact the sand, then pour small crushed stone or gravel to the top and compact it again. Then you can shed liquid cement mortar, but not necessarily. As an option for saving and cleaning the site: sand down, then construction debris (broken bricks, broken glass, fragments of slate - all additionally grind), it is good to shed a medium-liquid solution of cement, when it hardens, there is a little screening on top to align the blocks according to the level. Having installed the required number of blocks (in our version, 8, 4 on each long side), we align them with each other according to the level and put waterproofing on top - roofing material on bituminous mastic.

The proposed version of the foundation, of course, will not replace a full-fledged foundation, but with the help of a jack, you can always, if necessary, correct your structure or bring a capital foundation under it.

Also, if necessary, it will be possible to move the building to another point on the site.

On the resulting base we assemble the support frame, it is recommended to take a beam 150 x 150, but we will use 2 boards 60 x 150. We twist the boards tightly with self-tapping screws, plan the ends and get a beam 120 x 150. The beam is fastened into half a tree, but in our version we will fasten end-to-end with reinforced internal corners, external mounting plates, you can also use self-tapping screws with a solid depth. Many masters do not attach the support frame to the base, but I personally recommend doing this, because no one is safe from strong gusts of wind). I advise you to do this using the same corners or plates, so that you can unscrew it at any time without disassembling the structure.

Next, we attach the lags. The board will go to the logs along the height of the beam, in this case 150 x 40. The logs are fastened with special brackets, but if they are not available (or expensive), it is quite possible to replace them with a pair of ordinary corners. The distance between the lags depends on the thickness and strength of the material from which you are going to make the floor. If the floor is not insulated, but a moisture-resistant OSB of 18 mm is immediately laid on the logs, then the distance between the logs is sufficient 400 x 450 mm. By the way, as we collect, we do not forget to carefully process all the details with biosecurity. The support frame itself and the logs can still be processed by “working out”, but then you will have to use special means. If you are going to insulate the floor, then we fix the draft floor from below to the logs (we use waste material, trim), then a heater between the lags, then the same OSB 18 mm.

Next, we attach the lags. The board will go to the logs along the height of the beam, in this case 150 x 40. The logs are fastened with special brackets, but if they are not available (or expensive), it is quite possible to replace them with a pair of ordinary corners. The distance between the lags depends on the thickness and strength of the material from which you are going to make the floor. If the floor is not insulated, but a moisture-resistant OSB of 18 mm is immediately laid on the logs, then the distance between the logs is sufficient 400 x 450 mm. By the way, as we collect, we do not forget to carefully process all the details with biosecurity. The support frame itself and the logs can still be processed by “working out”, but then you will have to use special means. If you are going to insulate the floor, then we fix the draft floor from below to the logs (we use waste material, trim), then a heater between the lags, then the same OSB 18 mm.

The floor can be made from boards, but it will be more expensive.

With help circular saw we dissolve the boards 60 x 150 into "spare parts". Boards 75 x 60 will be used on vertical racks. It will take 20 pcs.: 4 pcs. - in the corners, 2 pcs. - on the short sides, 6 pcs. - on long sides. We will use boards 50 x 60 for vertical and diagonal fastenings, we will fasten them to the corners and mounting plates. We assemble a typical frame, if a window is planned in the barn, then assemble a box in the frame for them. The angle of inclination of the roof is determined individually, usually 15-20 degrees.

On the roof for a barn of this size, 9 rafters from a 50 mm board are enough, but since no one is going to dance on the roof, it is quite possible to take a 40 mm board. On the rafters, cuts are made to increase the area of \u200b\u200bfit to the frame. Rafters are attached to the corners or in a simple way - on nails, self-tapping screws. Removing the rafters from the frame is again at the discretion of the owner, but I would recommend at least 50 cm in front and at least 30 cm in the back.

We close the gaps between the rafters with scraps of boards from which the rafters themselves are made.

We lay the crate, the width and frequency of the crate depends on what material will be used for the roof. Under the profile iron C8, 11-12 narrow boards are enough.

We lay the crate, the width and frequency of the crate depends on what material will be used for the roof. Under the profile iron C8, 11-12 narrow boards are enough.

Before proceeding with sheathing the barn directly with a board, decide where the door will be, and it is better to hang it right away. It is better to take boards wide and not thin, optimally 25 x 150, it is better to prepare them in advance before sheathing, cut them to size and paint or process them in another way. We sheathe horizontally from the bottom up with a slight overlap of 2-2.5 cm (herringbone).

When working with wood, I always prefer a self-tapping screw: it can be carefully unscrewed, and not torn out with “meat”. After sheathing, we install windows (if necessary), ennoble the corners - two boards at an angle vertically, put door and window trim. That's all, you can proceed to the interior decoration.

When designing a foundation for a barn or a large utility block, the main aspect is to reduce the construction budget with your own hands and ensure the maximum possible resource. Therefore, floating slabs and MZLF tapes are rarely used; pile and column grillages are implemented. However, on difficult soils, with a high groundwater level and steep slopes, one should take into account the standards of the joint venture and ensure the protection of underground load-bearing structures with waterproofing materials and heaters from moisture and swelling, respectively.

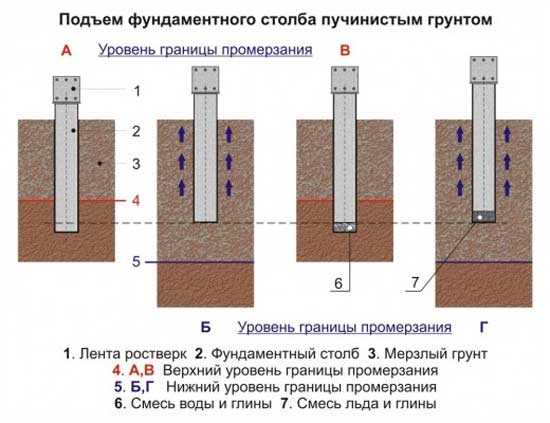

Choosing a foundation for a barn, an individual developer, building education not having, often stops on poles from wall blocks of the format 2 x 2 x 4 dm. He motivates this by the fact that the hozblok will be small and ultra-light, but no one has canceled the laws of nature:

- on clay soil, the pillars will either be overwhelmed by horizontal heaving forces, or squeezed out by the same efforts, but applied to the sole of the pillar;

- the low weight of the building here is rather a disadvantage, not an advantage, since it cannot balance the heaving forces;

- rain and melt spring waters will not bypass the structure, will destroy the reinforcement inside the reinforced concrete or contribute to the opening of cracks in concrete blocks when freezing after wetting the structural material.

Therefore, it is necessary to take into account the relief, find out the level of GWL and the structure of soils on the site. However, geological surveys will cost more than the entire turnkey construction, home master ordering this service does not make sense. The option “like that of a neighbor” is also devoid of logic, since the layers lie unevenly, quicksands are practically not determined from the surface, the actual service life may differ.

The easiest way to independently study the soil in a building spot is to test screw piles. The product is immersed manually, allowing you to determine the level of groundwater and the depth of the bearing layer by a sharply increased tightening torque.

Important! The reservoir must lie below the freezing mark of the region of operation in order to completely exclude heaving forces.

It is most advantageous to make a trial screwing for any foundation construction technology on heaving soils, embankments or dusty sands that sink under the weight of the building every year.

Barn foundation options

After independent impromptu geological surveys, one should take into account the nature of the soils in the building spot:

- coarse sand, rock or gravel soil - the most convenient option bases for the hozblok, enough pillars of brick or wall block, buried in two - one row, respectively, the grillage will become lower bar strapping "skeleton";

- sandy loam - due to possible swelling, the previous option will have to be supplemented with insulation of pillars under the sole or pour bored piles into fixed formwork from roofing material rolled into a cylinder, asbestos or polyethylene pipe;

Barn on bored piles

- loam, clay, difficult terrain, moist soil (ground water is high) - only screw piles will cost less, for which you do not need to drill wells, lay drains, insulate structures and waterproof them.

A monolithic columnar foundation and MZLF tape are not considered in this article in principle, since their construction will cost more frame shed, which is not economically beneficial for an outbuilding.

Due to the fact that a monolithic grillage for a utility block is unnecessarily expensive, all of these designs use wooden beams along the heads of piles and pillars. In this case, it is impossible to fill the floor on the ground, an overlap is applied zero level along the beams.

However, when building a barn for livestock, this option is not suitable in principle, since the wood rots and grinds with shovels during cleaning, and frequent repairs are required. Therefore, it is easier for calves and poultry houses to increase the construction budget, to fill in the ground monolithic belt, which is a modification of the strip foundation for light buildings.

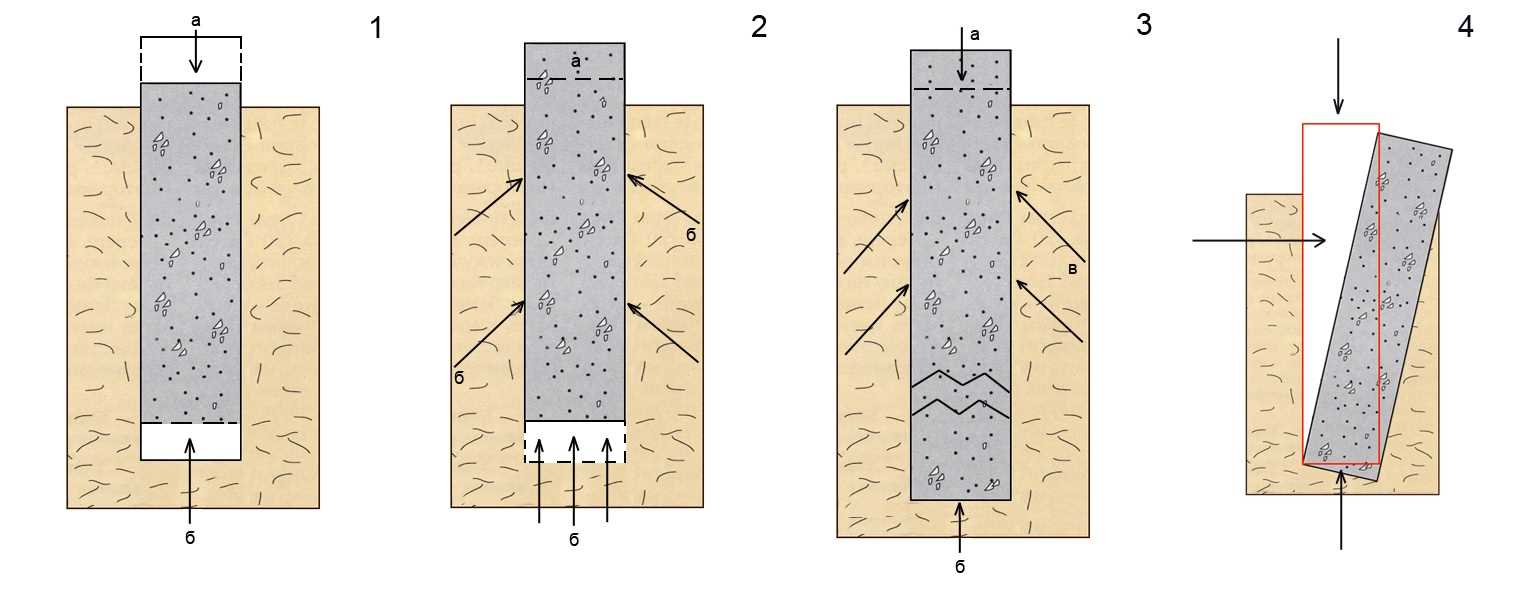

Screw piles

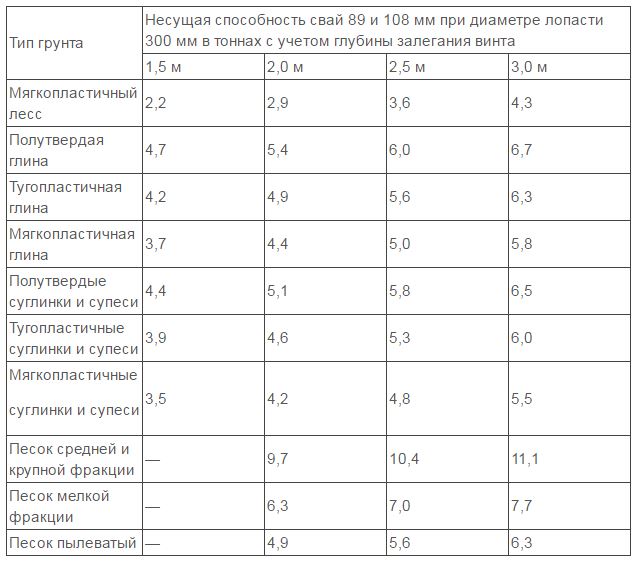

The main problem of this technology is the search for a manufacturer of SHS structures. In the presence of welding machine and the practice of using it, you can make screw piles with your own hands. Each manufacturer has a table of bearing capacity on different soils, which allows you to determine the pitch of the piles.

Load capacity table screw piles SHS

A frame hozblok rarely weighs more than 2 tons, so calculations will show that the foundation for a barn can be based on a single pile. However, it should be noted that rolled metal and lumber, from which grillage beams are made, sag under their own weight already by 2.5 - 3 m. Therefore, piles should be installed more often, with a maximum step of 1.5 - 2 m. The technology has the form:

- - cast-offs are taken out 1 m beyond the perimeter of the walls, a string or cord is pulled along them;

- leader holes - drilled hand tool or dug with a shovel, serve as a conductor for the pile blade, set the direction, depth 0.4 m, diameter slightly smaller size blades;

- immersion - SHS are screwed in with levers manually or with a drill with a power of 1.5 kW or more (you will need a torque amplifier - a multiplier, the issue price is 3 - 5 thousand or equipment rental);

- leveling - with a laser tool or a hydraulic level, a single horizontal level is marked on the body of each pile, the pipes are cut with an angle grinder with metal equipment;

- concreting - SHS cavities are filled with lean concrete to prevent corrosion of the inner walls, the procedure does not affect the bearing capacity in any way, the next stage can be started without waiting for the hydration of the cement stone;

- heads - a steel grillage is too expensive for a utility block, and wooden beams are easier to mount on the sites that the pile heads are equipped with, fixing is done with nails or anchors, since an ordinary hardened self-tapping screw can be cut off by horizontal loads.

Screw pile head for fastening the lower trim beam

Important! Heaving forces do not act on the piles, the outer edges of the pipes are protected by anti-corrosion. However, the structure of the building receives an underground, the perimeter of which must be sewn up. decorative material(usually asbestos-cement sheet, pasted over shingles, corrugated board or basement siding). To ensure ventilation of the underground, ventilation ducts 1/400 in size from the perimeter of the underground are left in the intake.

Drilling piles (bored)

The next option for the foundation of the barn on clay soils bored piles become, which you can do with your own hands using technology:

- offset of full-scale axes - marking is similar to the previous case;

- wells - drilled with a hand tool or a power drill, step 1.5 - 2 m, depth according to the calculation;

- formwork - made of roofing material rolled into a cylinder (the edge is fixed with brackets), polyethylene or asbestos-cement pipe;

- - wire twists to 4 vertical rods (diameter 8 - 10 mm, periodic section "corrugated") are attached to round or square clamps (smooth reinforcement, diameter 6 mm), the protective layer is provided by round polymer washers mounted on rods;

Framework options for reinforcing bored piles

- concreting - it is more convenient to pour the mixture through home-made funnels, it is better to compact it with rods or a deep vibrator.

Pillars from a wall block 40 x 20 x 20 cm

On non-rocky soils columnar foundations built in a few hours and are considered the cheapest option. If the soils are clayey, the developer has two options:

- do (the main condition for swelling is eliminated by draining melt / soil water), insulate the sole (due to small sizes buildings, high-density polystyrene foam will have to be laid around the entire perimeter and under the blind area to preserve the heat of the subsoil);

- or deepen the pillars below freezing, backfill the sinuses with non-metallic material (sand, crushed stone);

The columnar foundation on heaving soil should lie deeper than freezing

In the first case, the foundation for the barn will cost more, since the XPS has a high price. In the second option, the volume will increase sharply earthworks. Therefore, the technology will be considered on a flat area with a low GWL for coarse sand, rock or gravel soil:

- full-scale axes - they are carried out with cords along cast-offs, 1.5 m away from the pit;

- pits - an arable layer is removed under each pillar (usually 40 cm);

- pillow - an underlying layer 20 - 40 cm thick is sprinkled with crushed stone on wet soil or sand on dry soil, every 10 cm they are rammed with a vibrating plate or manually with a log;

- drainage - corrugated pipes perforated in the lower part are laid around the perimeter of the blind area, drain melted and storm water, covered with rubble, covered on all sides with geotextiles;

- masonry - pedestals are erected from ceramic bricks or blocks 20 x 20 x 40 cm, on which beams of a wooden grillage will be laid.

The pick-up is drawn up by analogy with pile-grillage foundations.

Pillars from car tires

Individual developers often use end-of-life machine wheels in construction and landscape design. Tires are used as a structural material for the foundation or formwork. Technologies differ, are selected depending on the percentage of clay in soils:

- on heaving soils - pits come off in the corners and in increments of 1.5 - 2 m under long walls, the wheels are stacked inside, inner space filled with crushed stone, which is compacted with a rammer, backfilling is necessarily inert material (for example, sand);

Pillars of tires are buried below the freezing mark and covered with rubble

- on rocky, crushed stone or coarse sandy soil - it is enough to remove the fertile layer, fill the pits with sand, compact it with a vibrating plate, make concrete grade M15 and higher, fill the inner cavity of the tire and compact the mixture with a bayonet.

The tire serves as a formwork for concrete and dampens soil movements

A significant disadvantage is large diameter rubber products. The wall is supported in the center of the wheels, at the corners the rubber protrudes on two sides, on straight sections - on one side. This makes it difficult to make a pick-up, without which moisture and rodents will penetrate the underground. Therefore, the cladding is mounted on a frame imitating a plinth or in sheet materials openings are cut out, and the wheels are painted for a more acceptable facade design.

Important! After the concrete hardens, the structure partially loses its damping properties, therefore, if swelling is possible, it is better to use the first method.

Monolithic ground belt

This technology is the only one that allows you to make floors on the ground, optimal for long-term operation in a poultry house or barn. In the initial version, options are possible depending on the soil conditions:

- non-rocky soils - no additional measures are required if the earth is dry, with a high GWL, drainage and waterproofing are necessary;

- clayey soil - along the perimeter of the building and under the blind area, it is necessary to lay insulation to preserve geothermal heat under an unheated building, make wall drainage and treat accessible concrete surfaces with waterproofing materials to prevent swelling;

At the following stages, the technology for erecting a monolithic belt with your own hands consists of operations:

- marking - cast-offs are removed beyond the perimeter by 1.5 - 2 m, for each wall 2 cords are pulled along the inner / outer edge of the foundation;

- earthworks - the fertile layer is removed entirely inside the center lines, since it is forbidden to make a floor screed on the ground on it;

- underlying layer - a foundation cushion of crushed stone or sand, a mixture of ASG with a thickness of 0.2 - 0.4 m, perimeter over size foundation by 0.2 m on each side;

- drainage - a closed circuit of perforated pipes lying at the level of the sole with a slope of 4 degrees in one direction;

- insulation - only on clay soil, the perimeter is lined with extruded polystyrene foam, the blind area is insulated at a depth of 0.4 m;

- formwork - plywood or board panels are mounted vertically, the sides are 5 cm higher than the design mark to avoid splashing of concrete during vibration compaction;

- reinforcement - frames made of longitudinal rods 6 - 10 mm, tied with rectangular clamps made of smooth reinforcement 6 - 8 mm;

- pouring - laying the mixture in a circle with simultaneous compaction (bayoneting with a bar or a deep vibrator).

Monolithic tape belt for a utility block with a blind area

Concrete care will avoid the opening of cracks, it consists in periodically moistening the poured sawdust. As an option, you can cover the concrete surfaces with a film, reducing the evaporation of moisture.

After stripping, all accessible faces of monolithic beams are waterproofed with bituminous mastic, coating or plaster materials, or is deposited on the surface roll material(for example, TechnoNIKOL).

Floor on the ground - floating screed, cut off from the foundation damper tape. The blind area is necessary for the removal of melt and rainwater from the walls of the barn.

Thus, any budget foundation from the options considered can be chosen for the barn. The main criteria remain the characteristics of the soil and the level of GWL, the relief and weight of the building, the type of floor / ceiling and the purpose of the utility block.

Advice! If you need contractors, there is a very convenient service for their selection. Just send in the form below detailed description work that needs to be done and you will receive offers with prices from construction teams and firms. You can see reviews of each of them and photos with examples of work. It's FREE and there's no obligation.