Everyone knows that metal garage doors in winter period frosted over and covered with a whole coat of frost. You have probably heard that you can use grease or other means to lubricate the garage door from the inside. Then supposedly there will be no frost. A much smaller number of people understand why this happens, and how it is connected with the fact that insulation needs to be carried out. garage doors.

Each of us studied thermal conductivity at school. If the garage is made entirely of metal, then frosting is not terrible for garage doors. The entire perimeter of the garage will freeze evenly. And in capital garages (where only the gates are metal), just the gates freeze over, because they are the most heat-conducting element.

Although the garage door is frozen, the walls will be fine. In this case, the gate in the winter period acts as a cooled coil in moonshine still. They condense moisture from inside the room and turn it into ice.

The temperature in the garage room affects the condition of your vehicle. And first of all - on its rubber-technical elements. The higher the temperature in the room, the more convenient it will be for you to use the car inside in winter. The temperature also sets the micro-climatic conditions inside the basement (if any) under the garage. To keep the heat inside the garage, you need to insulate it very carefully. This article will discuss how to insulate.

To determine whether it is necessary to insulate the garage door with your own hands, you need to understand one important point. Even without taking into account the winter cold, the usual thermal fluctuations during daylight and warm times of the day can cause condensation to form inside the garage. Constantly high humidity has a bad effect not only on the condition of objects, but also on the car body: the metal surface can rust, the electrical wiring can rot. Fungus and mold often appear in the corners of the garage.

After the condensate freezes from excessive moisture, it will crack finishing material. But there is great news - such a seemingly serious problem can be solved. Just choose the right insulation material, and then insulate the doors and garage doors. At the end of the work will not fall below 5 ° C.

So, the insulation of the gate will solve the problem with:

- metal corrosion ( metal gate garage, metal products located in the garage itself);

- "rotting" of the car in the garage, which drives in there still "warm". And if there is a considerable amount of cold ice in a closed room, then condensation will form on every metal thing. because cars and "rot" in garages;

- frost, which appears even with a sharp drop in street temperature (not necessarily minus). It makes it impossible to open the gate.

How to insulate garage doors? Let's take a look at this.

Preparing for insulation work

There are several ways to insulate garage doors. You can initially buy and install high-quality garage doors that already have insulation material. You can also do the thermal insulation of existing gates with your own hands. The last option will cost you less. By the way, the process itself will not take much time. And for insulation, you do not need to have special skills in construction.

Before installing the insulation, measurements of the area of the gate structure are made so that the total volume of the surface of the insulation can be determined. Where does garage door insulation begin? With the fact that the metal surface is cleaned of dust, dirt and other contaminants. Wash the garage doors and wipe them dry. Further, all holes and cracks are sealed with foam. When it is completely hardened, its protruding residues are removed using a knife.

How to mark up material for insulation?

The marking of the selected type of insulation is done depending on the structure and area of \u200b\u200bthe design of the gate in the garage. Perfect option markings - this is when all sheets of insulation are fully used, except for the seams and joints between the plates. But how to proceed to the insulation of the garage door from the inside, so that there is no excess material left? To achieve this goal, whole sheets of insulation are immediately used. And the space that remains is sealed with pieces of foam.

When cutting the insulation, the stiffening ribs of the gate are taken into account, because it happens that the corners of the insulation material protrude strongly above the canvas. The selected insulation is cut at an angle to the desired thickness.

How is the heater attached?

As a fixing material, polyurethane adhesive foam is used. If you have never used such foam before, then working with its application will bring you delight, since installation with it is reliable, fast and easy. The main advantage of such glue is the quality of the mounting foam.

Glue-foam is applied to the insulation. After five minutes, the sheet with the material applied to it must be glued to the cleaned surface of the gate.

Experts recommend starting the installation of sheets from the bottom of the gate. The first sheet is glued without strong pressing to the surface, otherwise the foam structure may be destroyed. After the first sheet has been installed, the subsequent ones must be glued with a standard gap of about a centimeter.

Sealant or mounting foam fill the seams that appeared between the sheets of insulation. After an hour, when the glue-foam is completely dry, the joints and seams between the sheets of insulation can be sealed with foam. Excess foam can be removed with a knife. In order for the insulation of metal garage doors to have an attractive appearance, the mounted insulation is finished with clapboard.

Choice of insulation material

Before insulating garage doors, it is worthwhile to deal with the following. The process of insulation directly depends on whether you managed to choose the right insulation material. When choosing, consider its quality and properties. Among the choice of heaters (and there are many varieties), pay attention to the three most popular options:

- on mineral wool;

- polyurethane foam;

- extruded polystyrene foam (polystyrene).

Each of them has a lot of advantages, but it is impossible not to take into account the disadvantages. For example, the fire resistance of foam plastic leaves much to be desired. But at the same time it has high moisture resistance and low thermal conductivity. At mineral wool, on the contrary, a high level of fire resistance, but minimal moisture resistance.

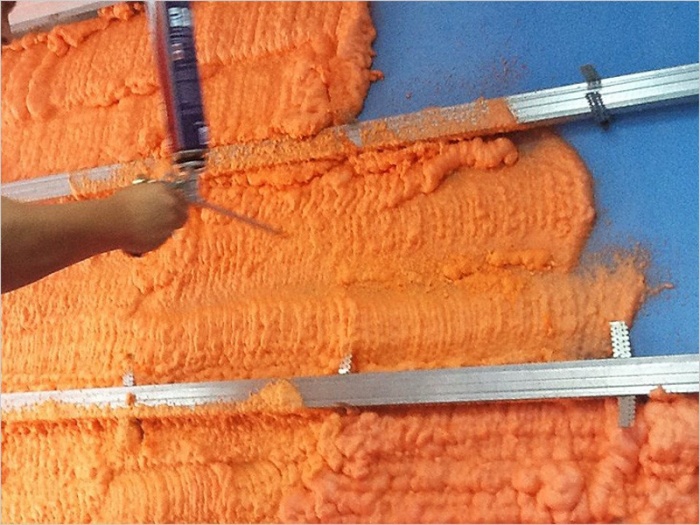

Polyurethane foam is latest technology regarding the insulation of the garage room from the inside. Spraying is quite effective and completely fulfills the task. It differs:

- seamless installation;

- light weight insulation;

- low thermal conductivity;

- high fire resistance;

- resistance to temperature extremes, chemical and biological aggressors;

- durability;

- strength;

- the ability to use any finish for the sprayed surface.

Mineral wool is a material in the form of fibers, which is produced through the processing of special rock. The material has low thermal insulation, but thanks to it the room is well insulated. Cotton wool is produced in rolls and plates.

Extruded polystyrene foam is considered a more expensive finishing option. It differs from other materials in the way of installation and gluing. Installation begins with the fact that a crate is being constructed and a film is stretched, designed to protect against moisture and vapor barrier. You can see how this is done here:

Note! When insulating garage doors, you need to understand that their surface should heat up quickly, perfectly pass heat inward, and also slowly release it outward. Do not forget to measure the area you are going to insulate in advance in order to purchase the right amount of materials and other important elements(glue or fasteners).

When choosing a heater, pay attention not only to thermal conductivity, but also to the presence of thermal inertia.

Garage door insulation

Thermal insulation with the help of any materials involves the use of a crate for the construction of the gate leaf, which will fix the insulation. The gate lining will then be attached to it. In order to make the crate, use wooden blocks with a section of 4 x 4 cm or 5 x 5 cm (depending on the design of the gate). The crate must be attached to the load-bearing frame of the door leaf: to a corner or a profile steel pipe.

To make a crate of wood, you need:

- prepare in advance required amount wooden bars. When buying, give preference to exclusively dry wood;

- treat the bars twice with an antiseptic compound (to prevent them from rotting in difficult conditions temperature fluctuations and high humidity)

- a bar is attached to each power element of the gate. Use a screw for this. To do this, mark the places where the holes will be, then use a drill to make through holes. The drill diameter must match the screw. When you attach the bars, do not forget to pre-drill holes in them with a thin drill. Then the screwed screws will not split them;

- if there is an air vent on the gate, it is bypassed around the perimeter with a crate. This also applies to castles;

- if there are no steel load-bearing elements on the central part of the gate, then the bars can be attached to one another in any way: with the help of corners, at the end, and the like.

What types of garage doors can and should be insulated? About swing gates

At most garage doors hinged construction, which, no doubt, needs to be insulated. The basis of the gate is a frame made of shaped pipes and steel sheet, which plays the role exterior finish. It is known that steel has a high thermal conductivity, therefore, many people know that non-insulated gates made of this material are not an obstacle to heat leakage from the room. It is important that there is a gate in the swing gates, which significantly reduces heat loss during the frequent movement of people. Therefore, if you are still building a garage, then you should order the gate already insulated and with a gate.

Now sectional and up-and-over doors are considered very fashionable. The sections or web of this product are a sandwich of sheet steel panels on the outside and polyurethane foam on the inside. Such a design already has the necessary thermal insulation properties. And additional measures for warming in this case are not required. Such types of gates, if you want, can also be equipped with a gate. This is what must be done.

Handicraft up-and-over gates are also for sale. However, garage door insulation does not have such models. fundamental differences from swing gates, because the basis is the same frame and steel sheet.

Roller doors are not insulated at all due to their special design. And they can not always be called garage doors, since they are much worse than all other types in terms of thermal insulation and anti-vandal characteristics.

If the garage for your car is located in a garage cooperative, then its arrangement consists in insulating the gate. As mentioned earlier, this will significantly reduce heat loss. Accordingly, this event is mandatory. The question is which material to choose. What and for what is better suited - we have already discussed.

So that the gate material does not suffer from corrosion due to the fact that condensate accumulates between the insulation layer and the metal, waterproofing of swing metal gates is carried out. Self-adhesive isolon can handle this function. It can be used as additional or basic thermal insulation. In this case, everything is decided by its thickness.

If the isolon has insufficient thickness, then polystyrene foam in sheets is glued to it. At the same time, they use tile adhesive or mounting foam.

Additional ways of warming

In addition to laying insulation, there are other options for insulating garage doors that reduce the release of warm air to the outside. Thanks to this action, it is really possible to create comfortable conditions in the room.

- The use of ordinary curtains, but not those used in apartments, but made of dense materials that perfectly hold back the cold and do not let it immediately into the room. They are made without unnecessary trouble: first, a steel thread or a thin rope is pulled. On it with the help of rings, well fixed to a dense material (for example, to a tarpaulin), you can attach a canvas. This method insulation is suitable for those who often have to open the gate or, due to certain circumstances, one gate leaf always remains open.

- In the early stages of building a garage, or many car owners forget to take into account the fact that less heat can escape through a small hole than when the gate is fully or partially opened. It turns out that it is better to make a small doorway at the gate. Then there is no need to plow open the entire garage in order to simply take tools such as, for example, hammers for driving nails. Therefore, when ordering a gate, ask to make separate doors for you in them.

- The joints between the wall and the gate are also, as you already know, subject to additional insulation. You can also put sills for less waste of heat, which will leave through the cracks. To ensure the function of insulation, use vinyl material with appropriate dimensions and thickness. Vinyl tape is attached along the edges of the joints where there are gaps. To fasten the tape, use nails or mounting adhesive. This is an additional barrier to heat loss.

Why is garage door insulation important?

First of all, the insulation of the garage door is taking care of your “iron horse”. If you manage to create really good conditions for your car, then it will serve you for a long time and regularly. After all, it turns out that cars can also “catch a cold” and “sick” in an overly damp or cold room. And, like every patient, such a car needs a special “treatment”, which, believe me, will cost you a lot of money. For this reason, as they say, prevention is always cheaper than cure.

In addition, many people use the garage not only as a parking lot, but also as a warehouse for old things or even a man's personal space. Often it is in the garage that they organize a small workshop in which sets are stored. different instruments, useful in the process of creating various things or carrying out repair "work".

Note

Also from the garage you can make a rest room for spending leisure time with friends. Therefore, carefully consider the insulation of this kind of room. Make sure your garage feels "warm" in the winter and cool in the summer. To do this, "should" try to create comfortable conditions for being inside the garage.

An insulated garage is necessary in our climate so that your beloved four-wheeled friend does not suffer from temperature changes. In addition, often the garage is used by the owner as a workshop or a place for communication and “exchange of experience”. Therefore, thermal insulation is an important event in the arrangement of any garage.

Why you need to insulate your garage

According to SNiP 21-02-99, in winter the optimum temperature in the garage should be + 5 ° C. At the same time, batteries will not deteriorate, and moisture will condense, causing corrosion. This can be achieved by installing in the garage heater and performing thermal insulation. But the main thing to do is to insulate the garage doors.

After all, heat from any room, as physics teaches, leaves in three main ways:

- Convection, or the transfer of heat by air currents. Air can escape from the garage when doors are opened, through ventilation, or through gaps in gates that do not fit snugly against the opening. The way to deal with this leak is to open not the gate, but the gate, and not for long; seal all cracks. And here ventilation holes should not be closed.

- Thermal conductivity, that is, the transfer of heat through the walls and material of the door to the outside air (or neighboring buildings);

- Radiation emitted in the infrared range by all heated objects.

The way to deal with the last two reasons is the same - you need to install thermal insulation. Let's see how to properly insulate garage doors, and why with foam plastic.

Some owners close the vents for the winter to save heat. It is not recommended to do this, as the storage conditions of the machine are deteriorating due to high humidity in the garage. And it's just life-threatening.

What is the best way to insulate a garage?

Most often, polystyrene or polypropylene is used to insulate garage doors.

Polyfoam has a number of advantages compared to other insulating materials:

- First of all, it is a low price and availability. Styrofoam in sheets of various densities and sizes can be purchased at any building supermarket.

- In addition, this material is easy to process. He is cut with an ordinary knife and glued with any glue or foam. The use of extruded polystyrene foam is even more convenient, since it does not crumble during processing.

- Styrofoam - very lightweight material, and the weight of the gate (load on the hinges and difficulties with closing) after insulation will practically not change.

- It is not afraid of moisture and does not absorb it, having an absorption rate of 3%.

- It is not subject to rotting, damage by fungus and pests.

- Service life of material - more than 50 years.

- At normal conditions(not in case of fire) does not emit harmful substances.

- And most importantly: it has a minimum thermal conductivity. If we compare the thermal conductivity of different building materials, then the foam will be in the first place. In physics, this indicator is denoted by the symbol "lambda" and shows how much heat will pass through a conventional cubic meter of material with a temperature difference of 1 degree. In foam plastic, it is one and a half to two times less than that of mineral wool, ten times less than that of wood, fifty times less than that of brick, and almost 2000 times less than that of iron.

Sometimes other heaters are used. For example, mineral wool. However, using porous garage door insulation is a mistake. The gates are made of metal, and the dew point will almost certainly be inside the insulation layer. Since mineral wool is permeable to moisture and hygroscopic, condensation formed inside will lead to wetting and loss of thermal insulation properties.

Which gates need to be insulated on their own:

- Swing. Most often, standard swing gates. They are two wings, that is, frame hinges from a corner, sewn on the outside with a metal sheet 2-3 mm thick. It is they who need to be insulated with foam. It is best to carry out insulation at the manufacturing stage, since for some operations it is desirable to remove the sashes. And this is not always convenient.

- Rollback. They are not as common in garages as they require a lot of room for the door to move. However, in the general case, their insulation is similar to swing.

- Lifting and turning. To open, such gates rise up, simultaneously turning parallel to the floor. There are models and factory-made, and home-made. Their insulation should be carried out in the same way, taking into account that the weight of the sash does not increase significantly, as this will require re-adjusting the opening mechanism.

- Lifting sectional. Most often they are made in the factory, from sandwich panels with a layer of insulation of about 45 mm and sealing the gaps between the sections. Warming is usually not required.

- Roller blinds. They are thin lamellas that are wound on a special shaft. They do not provide sufficient insulation and cannot be additionally insulated.

The procedure for installing foam insulation

So we found best material for warming. Let's look at how to properly insulate garage doors with foam, and what is needed for this.

First of all, you need to collect a set of tools.

You will need:

- drill with a set of drills;

- screwdriver or a set of screwdrivers;

- hammer;

- ruler, square and tape measure;

- jigsaw or hacksaw;

- construction knife;

- a metal brush (a brush on a drill) for cleaning rust;

- emery;

- brush (roller);

Then you need to purchase the necessary materials:

- wooden block 30x40;

- wood screws;

- foam plastic 40-50 mm thick;

- construction foam;

- antiseptic for wood;

- waterproofing coating for foam;

- facing material (best of all - OSB or waterproof plywood, 6-10 mm thick);

Now you can get to work:

- Prepare the gate - remove rust, clean peeling paint and clean the metal (with a brush and emery). Degrease the surface. Then coat the metal with an anti-corrosion primer.

- Cut the wooden bars for the crate into sizes and treat with an antiseptic.

- Perform waterproofing of the gate under the foam. You can cover the gate with bituminous mastic, or stick a waterproofing membrane.

- Mark and drill holes with a diameter of 4 mm for self-tapping screws in the stiffening ribs and the door frame (in increments of 25-30 cm). Countersink them for flush heads. (Part of the bars will have to be fixed at the end).

Attention! When fastening lower beam a problem may arise, as it cannot be reached with a tool. In this case, the sash must be removed. Or it is enough to fix it only at the end, this beam remains practically unloaded.

- Attach the bars in place with self-tapping screws. So that they do not crack, it is necessary to press them in place and drill a hole with a thin drill (2 - 2.5 mm) to the length of the self-tapping screw.

- Lay pre-cut sheets of foam in the gaps between the bars. When cutting, you can make a sheet 2-3 mm wider than the cell so that it fits as tightly as possible. When cutting, you should monitor the perpendicular position of the knife and do not break the cut line.

Attention! You can simply fasten the sheets into a spacer, on glue such as "liquid nails" or on mounting foam.

- After laying all the sheets, blow out the seams and joints with mounting foam. After complete drying - cut off the excess.

- Carefully measure the cladding sheet (OSB), cut it to size. Leave allowances for the lock and bolts. Having previously marked the location of the lathing bars, fix the cladding from the inside with self-tapping screws. Holes are also pre-drilled with a thin drill so that the bars do not crack.

If desired, paint in your favorite color. If necessary, glue a rubber seal around the edges of the flaps.

Cold and damp inside the garage have a negative impact on both the condition of the car and the garage itself.

According to the regulations, the temperature in a heated garage should never fall below +5 - under such conditions, the car will always be ready for work, it will not be damp and cold in the garage, mold will not appear, it will be comfortable to be in it. After all, the garage is not only the “home” of the car, but also a place for storage, a workshop.

For creating comfortable conditions the garage needs to be insulated. Separately, it is necessary to highlight the insulation of the gate, because it is through the gate, most often made of metal, that the most heat escapes, and it is more difficult to perform it than the thermal insulation of the roof or walls. How to insulate garage doors from the inside with your own hands?

What materials can be used

To insulate garage doors with their own hands, they most often use

- mineral wool,

- extruded polystyrene foam,

- Styrofoam,

- polyurethane foam.

Insulation with liquid polyurethane foam is a modern and effective, but expensive way. Spraying polyurethane foam requires special equipment. The advantages of this method are the formation of a uniform coating without seams and a long service life (up to 70 years).

You can insulate garage doors with mineral wool. For this material, it is necessary to lay waterproofing and vapor barrier, since cotton wool absorbs water, which worsens its heat-insulating properties. It is advisable to use basalt wool from well-known companies.

In terms of price / quality ratio, XPS and polystyrene are best for self-insulating garage doors. These insulating materials have the following advantages:

- have a low density, and therefore a small mass,

- have a low coefficient of thermal conductivity, that is, they do not transmit heat well,

- do not decompose under the influence of water and air,

- under observance of operating conditions do not emit harmful substances,

- does not absorb water well: in foam plastic, the water absorption rate is 1%, in XPS - 0.4%.

The video shows how to insulate a garage door with polystyrene foam with your own hands.

You will also need materials for finishing. It can be

- OSB boards-3 or OSB-4,

- plastic lining,

- wooden lining,

- profiled sheet

Finishing not only improves appearance warm garage doors, but also protects the insulation from external influences, for example, from mechanical damage and aggressive chemical substances(gasoline, solvents).

The most practical is considered to be facing with OSB boards. They have several benefits:

- lungs,

- easy to process them

- have a low price

- looks aesthetically pleasing

- have low vapor permeability.

Usually, plates 1 cm thick, 125 * 250 cm wide and long are used. For facing the gate, 1-2 sheets are required.

Wooden lining is beautiful, condensation does not accumulate on it, but it must be treated with antiseptic and flame retardants. Plastic lining looks good, but is soft and easily damaged. The profiled sheet is durable, but condensation accumulates on it.

Various gate designs and their insulation

Sectional

Such gates are an "accordion" that folds and rises to the ceiling. Industrially manufactured models already have their own polyurethane foam insulation, and all joints between sections are additionally insulated. Usually this is enough, but you can additionally glue foam sheets on each section.

lifting and turning

Such garage doors, when opened, rise up and turn at a right angle. You can buy them ready-made or make your own. These garage doors are already insulated. The insulation is a panel of polyurethane foam with a thickness of 4.5 cm, which is enough even for the northern regions.

Roller shutters

They are made of lamellas, like blinds, and are wound on a roller when they are lifted. A small layer of insulation can be made between the lamellas and on them, a thick layer cannot be made due to the design features, therefore in Russia it is not advisable to use such gates for heated garages.

Swing

The simplest and most popular design, made of sheet steel or profiled sheet, is quite durable. To minimize heat loss, even when installing the gate, a wicket should be provided in them. Do-it-yourself insulation of garage doors is easiest on this design.

Rollback

They represent a whole metal structure that moves along the rails. Such gates are rarely found in garages, however, if you have just such a system, they are insulated in the same way as swing gates.

What you need to insulate the gate

To insulate the garage door with your own hands, you will need the following tools:

- drill with drills for wood and metal,

- screwdriver or screwdrivers

- sandpaper,

- clamps,

- hacksaw or jigsaw,

- mounting knife,

- hammer,

- square,

- a metal brush or brush from a drill,

- roulette,

- roller,6

- iron ruler 1 m long.

Of the materials needed

- insulation,

- finishing material,

- wooden blocks for framing,

- mounting foam for sealing joints,

- composition for anticorrosive treatment of metal surfaces,

- wood preservative,

- for polystyrene and mineral wool - a waterproofing material, such as bituminous mastic, isolon, vapor barrier film.

Training

To properly insulate garage doors, they need to be prepared. Everything wooden surfaces must be treated with an antiseptic and antifungal agent with a brush. You may need one or two coats, each of which should dry.

Attention! It is necessary to apply an antiseptic with gloves - these compounds are harmful to the skin.

The gates themselves are cleaned of rust and peeling paint with a metal brush or a special nozzle for a drill. After that, they are cleaned with sandpaper and degreased with a solvent. When it dries, apply an anti-corrosion primer. The composition must be designed for use over a wide temperature range. Apply it in two layers: one along the gate, the other across.

crate

The next step is the crate. It is made from 4 * 4 cm bars and attached to the gate frame and to other elements on their surface, for example, to stiffeners. Before sawing the bars, you need to measure the garage door and make a drawing. The step of the crate must be at least 40 cm.

To fasten the crate in the frame, holes are drilled in increments of about 20 cm. If the frame is made from a corner, 3.5 * 30 mm screws are usually used for fastening to the frame and 4.5 * 70 mm for fastening the bars to the end. If the frame is made of profile pipe, then, accordingly, take longer screws. Fasteners should go into the bar no less than half of its thickness, and at the end of the bar - no less than 3 cm. Clamps are used to firmly press the bars to the frame. Then, using a screwdriver, screw them with self-tapping screws.

Warming

When cutting insulation, remember that the fewer joints, the better. Insulation is placed between the bars of the crate. 9

Styrofoam or expanded polystyrene sheets are lubricated with mounting foam or suitable glue- special for foam or "liquid nails". It is better to take a professional polyurethane foam, which increases in volume less and is conveniently applied with a gun. Glue must be applied around the perimeter and at the corners of the foam sheets and evenly distributed over the entire surface.

If mounting foam is used to insulate the garage door, the surface needs to be slightly moistened. The foam is applied to the sheet and left for a few minutes to increase in volume. Then the foam is glued to the gate. After 15 minutes, you need to press the sheets tightly again. After all the sheets are mounted, all remaining gaps and cracks are also filled with foam.

Mineral wool is fixed to the crate with dowels. Lay on top vapor barrier film, fixing it to the crate with a furniture stapler.

Important! If ventilation holes have been made in the gate, they must not be closed, this is dangerous! It is necessary to leave holes in the insulation layer.

After laying the insulation, OSB boards or other selected material are screwed to the crate. The sheets are cut so that the number of joints is minimal, and those that are available fall on the bars of the crate. Sawing OSB with a hacksaw or electric jigsaw.

Foam insulation

Warm garage doors can be obtained using mounting foam, which allows you to create a single surface without joints. For 7 sq.m. The gate will require approximately 5 cylinders of foam. The technology is extremely simple: foam is applied to the prepared surface, then it hardens, after which the excess is cut off. From above it can be plastered, painted, covered with OSB or chipboard.

Additional measures

In order to properly insulate garage doors, you need to make sure that they close tightly and without gaps. Usually they use a round seal with a thickness of 20 mm with a rubber "tail", for which they are attached to the gate with a perforated tape and self-tapping screws.

A seal is also installed at the bottom of the gate, but rubber ones are not suitable for this. For the lower part of the gate, brush profiles are used, which are also fastened with self-tapping screws.

If the garage is not insulated, then it simply turns into a canopy from the rain. Although the car is not a person, negative temperatures in winter are also contraindicated for him. First you need to insulate the garage door, through which most of the heat goes out into the street. Here it is possible both to get rid of drafts with the help of seals on the doors, and more complex work with the installation of heat-insulating materials.

Why and how to insulate the garage

Inexperienced motorists do not attach much importance to the insulation of the garage. There is a garage for the car and it's already good. And soon they are surprised to find that the body of the car begins to rust. It's all about humidity. Cold outdoor air, penetrating through the gate without insulation, causes a temperature difference, which leads to condensation.

Qualitatively insulated garage doors - the key to the longevity of the car

Misting in the garage occurs both in winter and summer. Here, both the cooling engine and the change in temperature outside during the day have an influence. As a result, high humidity contributes to the development of mold, which affects the car itself and everything in the room with it. Inconspicuous at first, but hardware, the body and electrical wiring begin to rust, and the interior trim cracks.

The second point is the garage itself. Car owners use it not only as a parking lot for cars, but also often equip a workshop, carpentry and just an interest club for friends in it. If the gates and walls of the garage are well insulated, then working inside will be much more comfortable. Repairing a car in the cold is still a pleasure.

Note! According to the standards, the temperature in the garage must be maintained at a level not lower than +5 0 C. This is enough for the engine to start without additional warming up, and the body does not rust.

In most cases, in the garage, the walls are made thick and reliable. The cold gets inside mainly through the gate, which must be carefully insulated. The task of such thermal insulation is to minimize leakage as much as possible. warm air through garage doors. A lot of heat comes from a cooling engine, you just need to prevent it from escaping into the street through the door holes.

If the garage is made of a profile, then the gates and walls will have to be insulated from the inside.

To minimize condensation, ventilation must be done in any room. But in the garage it is better to do with a simple hood with natural circulation. Moreover, it must be made so that it can be blocked. There is not too much heat anyway, there is no heating, air exchange during severe frosts should be reduced to a minimum.

Types of gates and features of their thermal insulation

There are several types of “doors” for entering a car garage. In some cases, it is easier to buy ready-made insulated garage doors, while in others you can make them warm with your own hands after installation. However, the desire to make something on your own is not always prudent. There are gate structures that are quite problematic to insulate with high quality.

The entrance to the garage can be closed with a gate the following types:

- swing;

- lifting and turning;

- sectional;

- rolled.

The swing design is the most common and consists of one or a pair of wings that open outward. These classic doors are in demand due to ease of installation, reliability and anti-vandal security. They are made of metal sheets 2-3 mm thick and reinforced with a corner. It is easier to make them and then insulate them with your own hands.

On the thermal imager, heat leakage through the garage door is clearly visible

In the lift-and-turn model, the sash rises to the ceiling. In most cases, these are products that are manufactured and insulated inside various materials in factory conditions. These one-piece sandwich panels are made from two sheets of metal and polyurethane foam between them. It is not necessary to insulate them additionally, it is enough just to carry out the installation correctly according to the instructions and install the seals.

Sectional doors are an improved version of the overhead door. Only they do not consist of a single canvas, but of several horizontally connected sections, which, when opened, fold like an accordion or move along the guides to the ceiling.

Roller blinds are a descending/rising canvas, consisting of separate narrow plates, which, when closed, are wound on a shaft under the ceiling. Like the sectional version, rolling shutters already come with insulation inside the slats. If a design is purchased without thermal insulation material, then it is difficult to insulate it yourself. It will be necessary to inject polyurethane foam into the sections.

Advice! If the garage is located in the northern regions, then it is better for him to choose swing gates. Only they can be well insulated with their own hands, creating acceptable conditions for storing cars inside.

Ready, already warm, rolled and sectional doors industrial production are not able to keep warm in severe frosts. However, it is rather problematic to additionally produce their thermal insulation. For the southern regions, they are quite suitable, and in Siberia it is better to install a hinged insulated alternative.

What thermal insulation material to choose

Before you start insulating the gates in the garage with your own hands, you need to correctly select the thermal insulation. The assortment line of insulating materials is huge, but not all of them will fit for insulating an automobile “house”.

For independent thermal insulation of garage doors are suitable:

- Slab foam or polystyrene.

- Sprayed polyurethane foam or penoizol.

The latter option will give odds to the rest in terms of fire resistance, but it is much inferior to them in terms of moisture resistance. Mineral wool is cheaper, but with equal thermal conductivity, its layer will be thicker and heavier than that of expanded polystyrene and polyurethane foam.

Comparative analysis the most popular heaters

To insulate garage doors, it is best to take one of the varieties of mineral wool. This roll material is easier to mount, but the main thing is that it is not afraid of fire. The same cannot be said for foamed and sprayed polymer-based alternatives. They, despite all the impregnations and additives, still remain fire hazardous.

Advice! Due to its non-combustibility, mineral wool - best option for thermal insulation of the garage. The less combustible and flammable materials used in the sheathing, the safer it is to leave the car in it.

The main advantage of mineral wool over other heaters is incombustibility.

You can also use heat-insulating paint. To apply it, a regular brush is enough. After the thermal paint dries, a polymer-ceramic film with high thermal insulation characteristics is formed on the door leaf. But it will have to be applied to the gate in several layers, forming a coating of the desired thickness and insulating properties.

After the door is insulated, the temperature in the garage will no longer fluctuate constantly, which will reduce the risk of condensation. Most heaters are mounted on the front side of buildings. But it is impractical and simply unreasonable to insulate garage doors from the outside. It is not for nothing that they are made of durable iron, protection from vandals and thieves will not interfere with the car.

The sections are already filled with a heat insulator and do not have cold bridges, you just need to follow rubber seals

If the insulation is fixed on the garage door from the outside, then it will not be possible to open it completely. The design of the hinged sashes will not allow them to be opened wide in this case, and sectional models they are simply not designed for such changes, they will not be able to add up even by half. Plus, the heat-insulating material from the outside can be set on fire. It remains only the option with installation from the inside.

How to insulate your garage door yourself

There are three methods for insulating garage doors:

- The use of sealants to close gaps.

- Installation of heat-insulating materials on the sash leaf.

- Hanging a curtain.

For thermal insulation of hinged and overhead gate All three methods can and should be used. And if a sectional or roll structure is installed at the entrance to the garage, then it will be possible to insulate it only with the help of the first and last trick.

Sealers - fight against drafts

No matter how accurately the gate is adjusted in size, gaps still inevitably appear. To eliminate drafts, the gaps between the wings, as well as at the points of their connection with the floor, ceiling and walls, should be closed with a sealant. It fills the gap and prevents the exit of warm air from the room.

To insulate rolling shutters, the sealant is glued inside the garage on the floor

The sealing insert can be:

- silicone;

- rubber;

- in the form of a nylon brush with wax impregnation.

Frost-resistant garage seals are available in the form of tubes and tapes with or without a self-adhesive backing. In the second case, you will need the appropriate glue to mount them. The brush version lasts the longest, but it also costs more.

Advice! The seals are mounted on the sashes, the gate frame or on bearing structures along the perimeter of the gate. But it is much better when the sealing material is glued on both sides so that the inserts are in contact with each other.

It is not recommended to use polyurethane foam to seal gaps in garage doors. Of course, with its help you can create a reliable barrier to drafts. However, with constant closing / opening of the doors, the foam layer will quickly collapse. Yes and on outdoors she starts to crumble. But as an option for one winter it is quite enough.

An air cushion is created between the two seals, which prevents heat from being drawn out of the garage.

In addition to factory products, a garage seal can be made from improvised means: a rubber hose or a piece of an automobile chamber. But the wear resistance of these options is obviously lower than the frost-resistant liners specially designed for this.

Insulation in garage doors - basic thermal insulation

Seals alone for high-quality thermal insulation of garage doors are rarely enough. Often you have to fully insulate the sash. At the same time, it is necessary to prepare their metal parts by cleaning them from rust and painting, and then sheathe everything from above decorative panels or a tree.

Scheme of installation of heat-insulating material in the door leaf of the garage

To insulate garage door leaves:

- Remove rust from metal door leaf, and then paint it for waterproofing with bituminous mastic.

- Fix a frame made of a bar with a section of 20–25 mm on the sashes with self-tapping screws.

- Fill the resulting honeycombs with insulation (foam polyurethane foam, cut and glue foam or insert cut-to-size mineral wool).

- Sheathe the OSB frame, clapboard or laminated MDF.

Wood boards for sheathing garage doors should only be used moisture resistant types. Ordinary fiberboard or plywood will swell and warp. It is better to take laminated sheets altogether. They cost more, but will last longer in a garage without heating.

On a note! The insulation fixed on the garage door can not be sheathed with wood. It is enough to close it with penofol or other dense foil material.

Sheathing with foil will additionally insulate the garage doors. Just fix it with a layer of aluminum inside, then the heat will be reflected back into the room. Not much, but even keeping that heat energy inside will help keep the humidity down.

Curtain - additional protection

As an addition to the warm gate at the entrance to the garage, you can hang a curtain to increase its thermal insulation. For it, it is necessary to pull the rope or fix it instead steel pipe with a diameter of 15–20 mm. The main thing is that the curtain should be made of a dense material (tarpaulin or PVC).

Tarpaulin panel well prevents heat leakage

Instead of a tarp, you can hang vertical stripes polyethylene. Similar protection is used in car washes and workshops. Extremely simple, but quite reliable - much less heat will escape from the garage room.

A selection of video lessons on the topic

Insulation technology for old garage doors:

How to seal gaps in garage doors:

Inner lining heated garage door

Self-insulation the entrance opening and the garage door should not cause difficulties. You should not consider this an excess, it is safer to store a car in a warm room without condensation, rust will not touch it. To do this, it is enough to insulate the garage doors with foam or mineral wool, and also close the gaps with a rubber or silicone sealant. And as an additional barrier to cold air, you can hang a canvas curtain.

The garage can be used for its intended purpose - as a parking lot for a car, as well as a workshop or warehouse where you can store inventory and various things. If you often do car repairs, then it is best to insulate the building. The most effective data work will be in the gate area. However, before carrying out such manipulations, it is necessary to familiarize yourself with the rules that state that it is better not to use porous heaters like mineral wool for the thermal insulation of the garage. This is due to the fact that it will shift towards the insulation, it will get wet, its density and thermal conductivity will increase.

Material selection

You should not try to save money by ordering a gate without a gate. Its presence allows you to keep warm inside the garage. It is better to immediately make gates not only with a separate door, but also with insulation. Among other things, the building must be equipped with a ventilation system, which can be exhaust and supply. The supply opening can be made in the gate. Insufficient ventilation can create life-threatening conditions.

Garage doors can be insulated different materials, however, one of the most effective is foam. This material has a low density, so the insulation will not exert additional loads on the structure. Polyfoam has a low coefficient of thermal conductivity, it does not emit substances harmful to human health, which is true under normal operating conditions. This thermal insulation does not interact with air and water, and the formed layer will last more than 50 years. Processing canvases is quite simple, for this you can use the available tools. It should also be noted that the water absorption of polystyrene is quite low and does not exceed 3%, but if we are talking about extruded polystyrene foam, then this figure is even less, it is 0.4%.

Thermal insulation of the gate: preparation of tools

If you decide to insulate the garage door with polystyrene foam, then at the first stage you need to prepare the tools. You will need:

- electric drill;

- screwdriwer set;

- brush for metal;

- screwdriver;

- wood saw;

- roller;

- core;

- clamps;

- square;

- sandpaper;

- hammer;

- meter tape measure;

- metal ruler;

- construction knife.

Preparation of materials

In order for the gate to look attractive from the inside, you can use a facing material, which is sometimes used as corrugated board, wooden lining, or OSB. As practice shows, it is best to prefer oriented strand boards, as they have many advantages, namely: the material is quite strong and reliable, easy to process, has low vapor permeability and eliminates the need for vapor barrier membranes to cover thermal insulation. Oriented strand boards can be purchased at a low cost, and after completion of the work, the gate will have an attractive appearance. For cladding, it is recommended to use OSB-3 or OSB-4 boards, the thickness of which should be 10 mm. Such material is intended for rooms whose conditions differ increased level humidity.

After you determine the size of the gate, you should calculate the number of plates. Each of them has standard sizes 1250x2500 mm. As a rule, the master manages with two canvases, and after the work, there are trimmings that can be used for other purposes. Insulation of garage doors is accompanied by the installation of a crate, on which facing materials will be attached. For the frame system, it is recommended to use a square section with a side of 4 cm. They are fixed to the bearing part of the gate, which is metal corners, sometimes - a profile pipe. Be that as it may, the crate must be installed around the perimeter and on the area of \u200b\u200bthe canvas. The distance between the elements of the crate should be 40 cm.

More about preparation

If the insulation of the garage door with polystyrene foam or expanded polystyrene will be accompanied by a further installation of the finish, then before starting the installation of the frame system, the wooden bars must be treated with an antiseptic. Depending on the composition to be used, one or two coats may be required. It is necessary to produce these works with a regular brush. During the drying of the bars, you can do the preparation inner surface gate, for this, the rust is cleaned to metal, it is more convenient to do this with a brush-nozzle on a drill. It is important to clean all loose paint, in hard-to-reach places ah, it is more convenient to use a brush with metal bristles. Sometimes experts advise resorting to the use of sandpaper, which the master must walk over the entire surface, this will improve the quality of adhesion of the primer to the metal.

At the next stage, the surface is treated with an anti-corrosion primer, it is applied in 2 layers. The direction of the second should be perpendicular to the first. As soon as you have waited for the surface to dry completely, you should take care of waterproofing, which is relevant in tandem with ordinary foam. If applicable, this operation is not performed. Waterproofing can be done with bituminous mastic, sometimes vapor barrier membranes are glued to the surface.

When warming is carried out, it is recommended to consider the photo even before the start of work, which will allow you to eliminate many errors. At the next stage, the crate is installed, the bars of the required length are cut to the size of the gate, they must be solid. In those places where locks and bolts are located, as well as ventilation grilles, it is necessary to make a frame of bars, installing them around the perimeter. To fix these elements, several holes are drilled with an electric drill, the distance between which should be 25 cm. For this, a 4 mm drill is used. In those places where the bars will be installed in the end, the holes should be 5 mm. Before drilling, it is recommended to mark and punch places so that the drill does not heat up.

For reference

When the garage doors are insulated with their own hands, the crate is sometimes required without installation facing material. At the same time, the installation of the lower row of horizontal bars may be accompanied by some difficulties, which consist in the fact that it is not possible to get the tool to hard-to-reach places. If you remove the gate, then these works can be carried out without problems, if not, then you need to attach the bar to the end, because the rest of the crate will take on most of the load from the facing material.

The nuances of installing insulation

Insulation of metal garage doors is usually carried out with foam, it should be cut only after measuring the space between the bars. About 3 mm of material is left on each side so that the foam is placed tightly between the bars. When cutting, it is necessary to ensure that the blade enters the thermal insulation vertically, if the blade is flexible, then it can lead to the side, which will certainly break the cut line.

Sometimes the insulation of garage doors with foam plastic is not at all accompanied by mechanical fixation of the material, because the cladding will press it to the base. You can use liquid nails, sometimes a mounting foam is used, which will come in handy later when sealing joints.

When insulating garage doors with polystyrene foam, it is recommended to use 40 mm slabs, which may have different sizes. When buying material, it is necessary to take into account the location of the crate so that cutting the foam is not accompanied by the formation of a large number of scraps. If possible, try to strengthen solid sheets of material. Experts recommend purchasing extruded polystyrene foam, since its water absorption rate is minimal, there is almost no need to protect such material from moisture, but such thermal insulation is more expensive. As practice shows, it is much easier to work with extruded polystyrene foam, it does not crumble when cutting.

for insulation

For the installation of bars, galvanized self-tapping screws for working with wood should be used, their size should be equal to 3.5x30 mm, as for fastening the side surfaces, they are fixed using self-tapping screws with dimensions of 4.5x70 mm, they are installed at the end. If the gate frame is made of a profile pipe, then the length of the self-tapping screws must be increased by adding the pipe section. Fasteners should enter the bar to a depth of 1/2 section; when installing the facing material, it is better to use screws with a press washer with dimensions of 4.2x32 mm.

Padding

Insulation of garage doors is usually carried out only after applying a primer to the metal surface. To do this, use an anti-corrosion agent that prevents the formation of rust in high humidity. The primer can be any, based on alkyd or synthetic resins. It should be designed for use over a wide temperature range. In order to degrease the surface, together with a primer, it is necessary to purchase a solvent.

Foam insulation

Insulation of garage doors with mounting foam is accompanied by the use of polystyrene foam or expanded polystyrene. As soon as the insulation boards are installed to metal surface, all joints must be filled with mounting foam. It is better to purchase its professional variety, which involves the use of a pistol. Such a composition expands less in volume, and the gun allows you to conveniently apply the mixture to the right place and in any quantity. In order to exclude rotting of the bars, an antiseptic should be used, it can be made on oil or water based, sometimes such mixtures are paint with antiseptic properties. If you decide to use ordinary foam, then it should be protected from moisture. This can be done using a vapor barrier membrane, Izolon self-adhesive insulation or bituminous mastic.

Warming of sectional works

Insulation of sectional garage doors is carried out using almost the same technology that was described above. Before starting, you need to choose a material, which can be foam, its installation is carried out using plastic dowels. This material is resistant to mold and mildew. If you want to ensure fire safety, then you should choose a foam that was made using flame retardants, in the event of a fire, the material will exhibit properties like self-extinguishing.

If it is possible to use special equipment, then polyurethane foam can be used for insulation. The work will cost more if they are carried out by a team of professional builders, but the efficiency will be on top. At the first stage, the gate is measured, as well as individual sections. This will cut the material according to the parameters. The insulation is glued to the surface, and mounting foam is applied to the joints.

When the insulation of the garage door joints has been completed, you can proceed to waterproofing. To do this, use Isolon, which sometimes becomes an additional means of thermal insulation. In some cases, this material is used as the main layer of insulation.

Conclusion

Insulating the gaps of the garage door is no less important than the thermal insulation of the leaf itself. To do this, you should use mounting foam, which has excellent adhesion with a huge amount of materials. However, before installation, the surface is moistened, because hardening occurs upon contact with moisture.