Few things can be identical to the pleasure of steaming in your own bathhouse at the dacha after a hard day at work. It is the bathhouse that allows you not only to acquire the purity of your body, but also to relax emotionally, restore your physical strength, improve your mood and emotional background. Despite the fact that the first baths were built in Egypt, steaming in them is considered an original Russian tradition. That is why every self-respecting summer resident who has all the necessary communications at his summer cottage considers it his duty to build or order the construction of his own bathhouse or sauna. If you want to order turnkey in the Moscow region, our company will carry out everything necessary work quickly and efficiently.

Selecting material and determining the size of the structure

The first thing you will have to deal with is choosing the necessary material, drawing up an individual project, in which you will calculate in detail the dimensions of the future bathhouse. In today's market, the priority for construction is wood of valuable species, such as cedar, spruce or pine. Of course, you can build a bathhouse from bricks or blocks, but the microclimate that will reign in it will not be so valuable. Wooden baths fit very well into any landscape design summer cottage, and natural ingredients fill the bathhouse with a special aroma that has a healing effect on the human body. In order to extend the life of a country bathhouse and prevent a flammable situation, it is best to treat the wood with antiseptics or other special compounds. A unique small bathhouse for a dacha in the Moscow region is usually calculated based on an internal usable area of 10 square meters for 2-3 people. Typically such a bath consists of:

- dressing room;

- directly to the steam room;

- shower room

The dressing room can be equipped with a rest room. Linden, alder or aspen are well suited for the interior decoration of a bathhouse. Abashi wood is often used, but its raw materials are quite expensive.

Where can I order the construction of a country bathhouse?

All work on building a bathhouse on a summer cottage can be done independently, but this requires special qualifications and certain knowledge, in addition, it will take a lot of free time. That is why it is better to buy a turnkey bathhouse for your dacha inexpensively and at the same time significantly save not only your own time, but also financial costs. A professional company for the construction of buildings made of natural wood guarantees:

- durability of the structure, its fire resistance;

- strength and reliability of the main structure;

- selection of high-quality materials that do not rot and crack.

A turnkey country bathhouse has a huge number of advantages; the price from the manufacturer is, perhaps, its main advantage. A country bathhouse will allow you to experience all the delights of relaxation and will give every steam bath lover new strength and energy.

A home sauna has the simplest design and small dimensions, which greatly facilitates its construction. The most important process is the arrangement of the stove and ventilation; everything else will not require much effort and material costs. An inexpensive and convenient do-it-yourself sauna at the dacha is not only an opportunity have a nice rest, but also a reason for pride.

To build a sauna, choose a site located near the house, where it is possible to dig a hole for a septic tank. It is undesirable for large trees to grow nearby, destroying the foundation of the building with their roots. For the convenience of those steaming in the sauna, there should be at least 2 cubic meters of room per person.

If we also add the size of the locker room and washing room, then the minimum construction area will take 10 square meters. m. The pit for draining water can be located under the washing room, which will save space.

The sauna body can be made of brick, timber, or even a metal frame, insulated and covered with siding. The interior must be upholstered with clapboard or ordinary boards. The choice of wood is very important: the best option is linden or alder. Conifers are very useful, inexpensive and have a pleasant smell, but at high temperatures they release resin.

The main element of the sauna is the stove. It’s best if it’s real, made of red brick and heated with wood. But the construction of such a furnace is only possible to an experienced master, therefore, without special knowledge it is not worth taking on its construction. The optimal solution would be to purchase a ready-made metal stove with a built-in heat exchanger and a tank for heating water.

Construction of the foundation

To build a columnar foundation you will need:

- support pillars;

- garden auger and shovel;

- tape measure and level;

- container for a septic tank;

- crushed stone and sand;

- concrete solution.

Step 1. Marking the area

First, markings are made: the location of the corner support is determined, a peg is driven in and the distance to the second corner is measured. Next, perpendicular and lines mark the sides and 2 more corners of the building. You should get a regular rectangle. The perimeter of the future sauna and internal partitions are marked using a rope stretched between the pegs. Support posts must be installed at each corner, under load-bearing walls at a distance of 2 m and at the intersection of internal partitions.

In addition to the location of the corner posts, you should immediately determine the location for the drainage pit. If there is a large container for a septic tank, the dimensions of the pit should correspond to the volume of the container, otherwise you need to dig a square pit with a side of 1 m and a depth of approximately 1.2 m. Holes for support pillars are most easily made using a hand drill. For a light wooden sauna, the depth of the holes for the foundation pillars is 40-50 cm.

Step 2. Preparing the pit

Sand is poured into a 15 cm layer at the bottom of the pit, compacted and a layer of crushed stone is poured. After this, install a container with perforated walls, level and strengthen the top. If there is no barrel, the walls of the pit are lined with bricks, leaving small, uniform gaps in the masonry for water to seep through. Starting from half of the pit and up to the top, the masonry must be made monolithic to avoid soil shedding.

Step 3. Construction of the foundation

Logs, metal pipes and concrete pillars are suitable for support posts. Be sure to choose the densest tree possible, preferably pine. To avoid rotting, the surface of the logs is thickly coated with bitumen mastic and dried.

Metal pipes are first treated with a primer with anti-corrosion properties. Crushed stone is poured into the bottom of the holes, after which the pillars are installed and leveled in height and vertically. Next, the holes are filled with soil mixed with sand, spilled with water for greater compaction, and compacted.

The top of the pillars is covered with roofing felt and the base beams are laid along the perimeter of the future building. The beams are secured with staples or nails to the support posts. Additional bars are installed inside the perimeter in increments of 20 cm and parallel to each other. This will be the base for the flooring. You can replace the timber with a reinforcement grid, install formwork and fill it with concrete.

Even small brick buildings require skill, especially when building corners. It is much easier to build a frame from timber and cover it with boards. After insulation, such a building will be no worse than a brick one. You can assemble a frame from glued or profiled timber, which is the most popular option for a country sauna.

So, to assemble the frame you will need:

- timber 100x150 mm;

- wooden slats 40x60 mm;

- support beams;

- level;

- screws or nails;

- primer;

- metal staples;

- glassine;

- mineral wool;

- foil vapor barrier;

- boards for cladding.

Step 1. Installation of supporting structures

First, the corner support beams are mounted: they are secured with spacers, aligned vertically using a level and secured to the base with metal brackets. From above, along the perimeter, the frame is secured with beams. Next, intermediate vertical beams are installed along the walls every meter and secured with brackets to the lower and upper trim.

Door and window boxes, nail transverse slats to strengthen the structure. At the corners, braces made of timber are installed, directed in different directions.

Step 2. External cladding of the frame

The wooden frame is sheathed with boards 3 cm thick. Work begins from the corner and from the bottom: the first board is applied to the supports parallel to the ground, leveled so that the edge does not go beyond the corner, and nailed. It is not advisable to join the boards in the middle of the span; their edges should meet at one of the vertical posts. The rafters are sheathed last, and it is necessary to leave a hole in the roof for the chimney.

Step 3. Insulation of walls, floor and ceiling

The inside of the walls is covered with glassine or polyethylene film to waterproof the insulation. The film is overlapped along the edges by 10-12 cm, and the seams are sealed with construction tape. Mineral wool slabs are tightly inserted between the frame beams, the thickness of the insulation layer is at least 10 cm.

The top of the cotton wool is covered with foil material, which acts as a vapor barrier. The foil side must be placed on top to reflect heat from inside the room.

The floor and ceiling can be insulated using polystyrene foam 10 cm thick. The base boards are covered with polyethylene film, the edges of which should extend onto the walls by about 3-5 cm. Foam plastic is laid between the joists, cracks and gaps in the seams are blown out polyurethane foam, and a screed is poured on top. You can also make a wooden floor, although the boards will last less in such conditions. You can lay tiles over the screed - they are easy to clean and are not afraid of changes in temperature and moisture.

Where the stove will be installed, a fireproof base must be made: a square metal sheet, the dimensions of which exceeds the area of the stove, is nailed to the floor, and bricks are laid on top edgewise in dense rows. A clay-sand mixture serves as the binding solution. Only red fired brick is used; other types are not suitable.

The ceiling is insulated in the standard way: polystyrene foam is inserted between the ceilings, all cracks are filled with foam, and the vapor barrier layer is secured with foil on top using a stapler. After this, the wiring is laid, the walls and ceiling are sheathed with clapboard.

Interior arrangement

After the construction and thermal insulation of the building, you can proceed to the main part - installing the stove and interior design saunas. It is very important to properly insulate wooden surfaces located near the stove. For the partition adjacent to the furnace, red brick and aerated concrete blocks are ideal; in extreme cases, you can use cladding made of galvanized sheets.

To set up a sauna you will need:

- metal stove;

- stainless steel tank;

- connecting pipes and tap;

- boards for benches;

- self-tapping screws;

- roulette;

- screwdriver;

- chimney with a protective cap.

Step 1. Installation of the furnace

Lay out a wall made of brick or aerated concrete blocks, the width corresponding to the width of the oven. If you don’t want to mess with bricks, you can cover the adjacent walls and part of the ceiling with special felt, and then cover it all with galvanization. A stove is installed on a brick base, the chimney is led to the attic, pipes and a water tank are connected to the stove.

To avoid fire of the rafter system, a box is knocked down from boards around the chimney and filled with a mixture of sand and clay. The pipe ends up in the middle of the box and cannot heat the wooden elements of the building. A protective frame is also built around the stove from scraps of lumber. Wooden fencing can be round, square or rectangular; it should not rise above the heating elements by more than 5 cm. A distance of 7-10 cm is left between the heater and the fence.

Step 2. Installing shelves and doors

The lower shelf is attached to the walls at a level of 50-65 cm from the floor, the upper shelf - at a distance of 1 m from the sauna ceiling. Usually they make 3 shelves with a width of 30 cm, depending on the build of the household. To make shelves, use the same boards as for internal lining. They are first thoroughly sanded, impregnated with an antiseptic, and then with a special varnish.

It is recommended that sauna doors open outward. You can install a frosted glass window in the door leaf. The bottom edge of the door must be trimmed by 5 cm to ensure air flow. Roller or magnetic latches are used as locks, which, if necessary, open very easily.

Step 3. Laying stones

For a sauna, choose stones that are round in shape, without cracks or deep potholes. Before installation, they must be washed and dried well. First, large stones are laid, trying not to leave gaps between them, and then the remaining space is filled with small stones. During the operation of the sauna, the stones will have to be periodically inspected, washed and broken pieces removed.

Step 4. Finishing

At the final stage, lamps, towel hooks, and a clothes hanger are installed. It is best to mount light bulbs above the doorway or in the corner opposite the shelves. To avoid getting burned by a lamp in a cramped room, it is recommended to cover it with a decorative grille. It should be taken into account that all lighting devices must be moisture resistant.

Video - Do-it-yourself sauna at the dacha

Everyone who has a suburban area wants to make the most of its space. And to lay out a garden and plant a vegetable garden and have a house. And for rest and relaxation, of course, you definitely need a bathhouse.

Mobile sauna trailer - an ideal mini-tower option

There is absolutely no reason to be upset and upset if the area of your site is not large enough to build a bathhouse of standard sizes. You can consider a project for a compact mini bathhouse in the country. A small sauna built with your own hands meets the needs of steam lovers just as much as a standard one. And in terms of saving free space and material costs, its construction will certainly be of interest to the thrifty owner.

How to determine the size of a mini bath?

If the ground is sufficiently dry and hard, then you can use a simplified version of the foundation. First, flat stones are laid around the perimeter of the future structure, then the same stones are laid in the interior of the foundation. The free spaces between the stones are filled with clay and compacted thoroughly. A layer of wooden beams is placed on top, treated over the entire surface with hot bitumen.

Walling

Arrangement of water supply and drainage

Heating system

Ventilation and lighting of mini baths

Single mini sauna on the street

Mini sauna - barrel without foundation

To assemble such a bathhouse, you will need lightweight insulated panels, which are a frame made of wooden beams covered with thin boards. The size of one frame is 185x60 cm, and in its manufacture they use timber with a cross-section of 3x6 cm and boards 1-1.5 cm thick. To insulate and provide heat and vapor barrier, the panels are filled with foam plastic or mineral wool, covering it on the inside with polyethylene film or aluminum foil . The outer side is covered with glassine or roofing felt. Then the panels are covered with clapboard.

Mini sauna indoors

Cabin - mini sauna single

Portable compact mini steam room in a city apartment

Steam cabin in a regular small bathroom

How to build a mini-sauna with your own hands in the country or at home

If the area of your site is not large enough to build a bathhouse of standard sizes, then you can consider the project of a compact mini bathhouse in the country.

A small do-it-yourself sauna in a country house or country house

It is difficult to imagine modern country or country houses without a bathhouse, which has become an obligatory component of a country holiday. But what to do if there is not enough money or very little money to build a full-fledged steam room? land plot, on which it will not be possible to place a separate building? For those who experience similar problems, there is only one way out - a mini-sauna with your own hands in the country.

Choosing a place in a country house to build a mini-sauna

As a rule, a steam room is set up in one of the rooms of the house, the main thing is that it is suitable in size and it is possible to organize power supply and ventilation in it. For example, a do-it-yourself mini-sauna in a country house can be placed in the attic, basement or on the balcony if the house is two-story. An ideal option if it is possible to make a direct exit from the sauna to the shore of an artificial or natural reservoir.

Choosing a location for a mini-sauna

Equipping a mini-bath in country house, it is possible to save significant funds on the installation of communications: sewerage, water supply, electrical wiring, but at the same time not lose square meters of internal space.

Layout and dimensions of a mini-sana in a country house

Setting up a sauna with your own hands in the first stages includes developing a diagram and determining the dimensions of the future home bath. The size of a small steam room is designed on the basis that one or two people will steam in it. Each person in the booth must have a volume of at least 2 m3. In this case, the ceiling height should be at least 2 m. The most successful minimum size is 2 x 1.8 m, when a bench can be installed on each side.

Layout and dimensions of the mini-sauna

A do-it-yourself mini-sauna at the dacha, the drawings of which include the minimum allowable height and area, allows you to significantly save on electricity and time to warm up the steam room. Because the larger the cabin, the more electricity it will require to operate.

Finishing the floors in the sauna

We begin the construction of a home bath with finishing the floors. For their base, concrete is used, lined with natural or artificial stones. You can also lay the floor in a steam room with tiles - a practical, inexpensive and common option.

According to its characteristics, a terrace board (thermal wood) is ideal for installing a floor in a sauna, as it can withstand high temperatures, changes in humidity, dynamic loads and has a corrugated surface, beautiful texture and long-lasting shade.

Installation of a wooden frame

Before making a frame, you need to make sure that the room is rectangular by measuring and comparing its diagonals - they should be the same. If necessary, make adjustments using the frame beams, retreating the required distance from the walls.

The elements of the frame are dry pine beams, with a cross-section of 5x5 cm. Depending on how the walls will be covered with clapboard, they are placed vertically or horizontally, in increments of 400 mm. To thickness thermal insulation material an indentation is made from the main wall (50 - 100 mm).

In order to subsequently carry out the correct installation of an electric heater, which is installed on a finished wall, it is necessary to provide embedded elements (additional frame bars).

Organization of ventilation in the mini-sauna

For the steam room to work correctly, you need a well-executed do-it-yourself sauna ventilation system that can provide no less than a six-fold change of air in the cabin per hour.

For this purpose, a supply hole is made near the heater and the floor to allow fresh air to enter the bathhouse. On the opposite wall, closer to the ceiling, there is an exhaust opening through which hot air will enter the common air duct. Another ventilation hole is made in the ceiling, closed with a damper, designed for quick and complete ventilation of the sauna between sessions. This option for organizing ventilation is the most common.

Depending on the design of the steam room and the features of its location, ventilation diagram may change.

Electrical supply for mini-baths

Since the steam room is a room with increased danger and high temperatures, it is necessary to pay special attention to the arrangement of the power supply. For hidden electrical wiring you need to use wires with reliable heat-resistant insulation that can withstand up to 170 - 180 0 C. It is not allowed to connect wires inside the bathhouse, install electrical sockets and switches, as well as control devices.

Lamps should be used only specialized ones - heat-resistant (protection degree IP 65). It is practical to place them under benches.

All electrical equipment in a home bath must be connected through high-quality circuit breakers that protect the electrical circuits from short circuits.

Organization of thermal insulation of a mini-bath

Insulating the sauna from the inside with your own hands is necessary to ensure quick heating of the steam room and save on energy resources, and, accordingly, on the power of the heater. Thermal insulation made from basalt-based mineral wool has become widespread, since it does not absorb moisture and has vapor-permeable and non-flammable properties.

Mineral wool is inserted into the wall frames in mats 5 cm thick. Pay special attention to the thermal insulation of the ceiling, since large heat losses occur through it. The thickness of the mineral wool should be at least 10 cm. The wool should be attached to the rough wooden ceiling using long self-tapping screws.

Having completed the installation of mineral wool, the entire frame must be covered with special foil paper. It has excellent reflective properties, and also perfectly retains radiation energy and creates a “thermos effect”.

After completing the process of insulating the home steam room, it must be sheathed with clapboard.

Selecting and assembling a stove with your own hands for a mini-sauna

A self-made electric heater for a sauna will help to significantly save money on setting up a mini-steam room, and it would be better to entrust the connection of the finished device to professional electricians. It is very compact, making it ideal for small steam rooms. In addition, the heater is quite easy to install and does not require the purchase of expensive materials.

Electric sauna stove

In order to assemble an electric sauna stove with your own hands, you need to carry out the following steps:

- we draw up a drawing of the future stove, taking into account the size of the cage for stones;

- we calculate the number of heating elements, depending on the required power;

- We assemble the stove - we fix the heating elements on the frame and connect them with jumpers. We use a sheet of steel 3 mm thick as a base, we attach the remaining parts to it using bolts and welding;

- We place stones on top as tightly as possible into the finished frame;

- install a protective casing made of steel sheet;

- we connect the electric furnace using a serial or parallel connection of heating elements;

- We check the functionality of the oven.

You can also make a wood-burning sauna stove with your own hands, which is a classic option. It has universal properties that allow you to maintain temperature regime in the bathhouse at the required level with minimal costs.

A stove for a wood-burning sauna with your own hands can be assembled in the following options:

- the stove frame is welded from sheet steel 4–5 mm thick, and having installed it at the installation site, it is covered with refractory bricks;

- The stove is made of special refractory bricks.

Installation of benches

Shelves in the sauna can be built with your own hands from planed timber with a cross-section of 5x5 cm. Its design will completely depend on the size and type of benches. If the ceiling height is 2 m, the upper shelf should be made at a level of 1 m. The width of such a lounger should be at least 70 cm. The lower shelf is installed at a height of 60 - 70 cm, its width can be 40 - 50 cm, since it is intended for sitting.

Mini-sauna in the country: how to make it yourself

If you want your holiday at the dacha to be complete and with health benefits, then start building a small sauna in a country house that will take up a minimum of space.

Do-it-yourself comfortable mini-steam room in a private home or country house: step-by-step arrangement technology

Agree, it’s very convenient to have a mini-steam room right in your home or country house, and not just in personal plot? The ability to take bath procedures at any time of the day or night, reducing energy costs, and prompt heating are just a small part of the advantages of a compact bath over a traditional one. But the most important thing is that it is much easier to equip it with your own hands. If you are increasingly thinking about a mini-steam room, here’s what you need to consider: step-by-step technology its structures with detailed photos and useful videos.

Agree, it’s very convenient to have a mini-steam room right in your home or country house, and not just in personal plot? The ability to take bath procedures at any time of the day or night, reducing energy costs, and prompt heating are just a small part of the advantages of a compact bath over a traditional one. But the most important thing is that it is much easier to equip it with your own hands. If you are increasingly thinking about a mini-steam room, here’s what you need to consider: step-by-step technology its structures with detailed photos and useful videos.

Design and assembly of the steam room

The first stage of installing a mini-steam room in a house or country house is drawing up a project. It will protect you from mistakes at all subsequent stages of construction. The project must necessarily contain:

- general drawing of the steam room;

- frame dimensions;

- location and connection diagram of the heating device and ventilation;

- internal filling of the steam room.

Determine the size of the mini-steam room at your discretion: depending on your needs and the available space. Practice shows that the optimal dimensions for a home bath are 2x2 or 2x1.6 m. As for the location, most often a steam room is installed in the bathroom, since all the necessary communications are already there. Although, if square meters allow, you can allocate a loggia or even a separate room for it.

The second stage is the installation of the steam room:

- Pour the floating concrete floor onto the marked work area.

- Assemble the frame of the bathhouse from vertical bars. Install the elements in 60 cm increments and secure them with screws and corners.

- Install a door between a pair of bars: a compartment, a door with hinges or Velcro, a glass structure - whatever your budget and imagination allow.

- Lay ceramic tiles on the concrete floor. Subsequently, it will need to be covered with wooden gratings.

- Cover the outside of the frame with wood panels. These can be boards made of coniferous or hardwood, or lining. Install the panels horizontally and secure them to the frame with screws and dowels.

Advice. To prevent moisture from penetrating into the sheathing, install wooden panels with a slight overlap over each other.

Thermal insulation of walls

The recommended layer of mineral wool is at least 5 cm. It is laid on the inside of the frame between the bars. But the wood cladding sheets are first covered with aluminum foil - it will serve as an intermediate layer between the thermal insulation and the outer cladding and protect the wood from condensation.

Mineral wool is laid overlapping on the foil. A layer of waterproofing is again placed on top of the insulation - aluminum foil can also be used here. In this case, the reflective layer of material should be directed not towards the mineral wool, but towards the steam room. The foil should be fixed construction stapler on frame bars. And the waterproofing sheets need to be connected to each other with tape.

After laying the thermal insulation, sew up the walls of the mini-steam room from the inside. You can use the same wood materials as for the external walls.

Heating and ventilation

To heat a mini-steam room in the house, the easiest way is to use an electric heater. Its power is calculated according to a simple scheme: 1.-1.5 kW per 1 sq.m. area. That is, for a home bathhouse 2x2 m, a device with a power of 4-6 kW will be sufficient. It can even be connected to a standard single-phase power supply.

The electric furnace is placed either on the wall or on the floor, but always near the door - this is necessary so that the cold air coming from outside is immediately captured and warmed up by hot air currents. The stove is equipped with a compartment for stones - when poured with water, they form steam, which increases the humidity in the mini-steam room.

The electric oven is also equipped with a thermostat, thanks to which the required comfortable temperature is maintained in the steam room.

Another mandatory stage in arranging a mini-bath in the house is organizing ventilation:

- At the bottom of the floor near the stove, make a supply hole for air in one of the walls of the steam room.

- Make an exhaust hole in the wall as far as possible from the supply opening and from the door.

Both openings must go into one room, which, in turn, must have a ventilation exhaust duct leading to the street. An electric fan should be installed in the hood.

Interior arrangement

Finally, the final stage of creating a mini-steam room is its internal filling. For ease of use of the bath you will need:

This is a minimum set, which, if the dimensions are correctly calculated, will fit perfectly in a mini-steam room. In order not to make mistakes with the dimensions, all filling elements must be included in the drawing at the stage of creating the steam room project.

All components of the bath must be made of wood that does not contain resin and is characterized by low thermal conductivity: linden, spruce, aspen. You can make benches and shelves with your own hands, but it is better to buy footrests and headrests in special stores.

Also an important component of filling a mini-steam room is lighting. These should only be heat- and moisture-resistant lamps. To ensure safety, switches should be placed exclusively on the outside of the bathhouse.

Thus, a mini-steam room in a private house or country house is not at all a hard-to-find exotic, but a completely feasible idea. For its successful implementation, you need to think through every moment: design, size, finishing, heating, ventilation, interior arrangement - by paying maximum attention to each of these points, you will get a functional and comfortable mini-bath that will give you a lot of pleasant moments.

Do-it-yourself mini-steam room at the dacha and in a private house: photo, video

If you are increasingly thinking about a mini-steam room, here is a step-by-step technology for its construction with detailed photos and useful videos.

Mini sauna for a summer residence: how is it different from a regular one and is it difficult to build it with your own hands?

If you pay attention to the dacha plots that were allocated to ordinary citizens in Soviet times, then the thought immediately arises only about planting vegetables. After all, there is no room left for anything other than a small house. But spending summer time at the dacha, I also want to take a steam bath in the bathhouse after a hard day of work on the site. Few people know, but even in a small area it is possible to install a steam room. Moreover, this will be a purely budget option that does not require special investments. Surely some have already guessed that today we will talk about such a building as a mini bathhouse for a summer house, as well as how to do all the work with your own hands.

A mini sauna at the dacha is really very necessary

Mobile sauna in the countryside made of wood - simple and tasteful

Mini sauna in a country house of 6 acres - myth or reality?

What are the usual reasons why a summer resident does not decide to build a bathhouse on his property? Of course, this is the lack of funds for its construction and the necessary space on the site. As for a mini sauna in the country, it can be an ideal solution to these two issues. Let's try to figure out whether it is worth undertaking such construction or whether it might be easier to purchase a ready-made one and install it on the site.

Let's start with the fact that buying a ready-made room for a bathhouse is an easier solution, but at the same time, the summer resident faces another problem - after all, he really needs a budget option. And this cannot in any way include the acquisition of a finished building. It is for this reason that today we will consider the construction of a bathhouse with our own hands. Although we will definitely dwell on the cost of ready-made ones, but a little later.

Everyone puts a different meaning into the concept of “small bathhouse in the country”. After all, for some, even a plot of 20 acres is considered small. But we will consider the average garden plots of 6-8 acres. This means that the bathhouse on them should not occupy more than 4-6 m in length and 2-3 m in width. First of all, we’ll figure out what bathhouses can be like on a summer cottage, what they can be built from, and only after that we’ll decide how to do all the necessary work.

Materials from which you can make a small bathhouse in your summer cottage

First you need to understand what the structure will consist of. It could be:

- Wooden beam;

- Edged board;

- Metal frame covered with wood;

- Plastic corrugated sheeting (not suitable for stove kindling - only steam);

- Brick or foam block.

Of course, the most common material for such a building was and remains wood. After all, if you think about it, what kind of bathhouse is made of plastic and similar materials. Naturally, metal is out of the question at all, although some recommend it for the frame of a building. And yet, not everyone in their yard has the opportunity to process and weld metal, and therefore we will focus on an option consisting entirely of wood.

A mini bath can also be built on a metal frame like this

Frame baths as the simplest type of construction

Surely in childhood everyone built “headquarters” in the forest between the trees. Something similar will happen in this case. The initial stage is the assembly of the skeleton, like the skeleton of the future structure. The interesting thing about building a frame mini bathhouse with your own hands is that you can even do without a foundation as such. Of course, it won’t be worse if a good foundation is made, but the main task is to ensure that the frame settles tightly on the soil. Now we will try to explain step by step how construction should proceed. To make it clearer and more comprehensive, let’s take a larger bathhouse as an example of a frame, but there will be no changes in the algorithm of actions, and therefore there should be no problems during construction.

Let’s say right away that all the work was done on a computer, this is a complete project. But this only applies to the frame of the bathhouse. We will observe everything related to finishing and cladding in photo examples.

At first glance, everything seems very complicated. But when you start working, you can understand that the eyes are afraid, but the hands are doing the work. Although it is difficult to assemble a frame mini bathhouse with your own hands, it is quite possible.

A bathhouse made of boards - is it much more difficult to build?

In fact, assembling a bathhouse from boards with your own hands is a little more difficult than a frame one. The work algorithm looks something like this. To begin with, just like for the frame, a base frame is assembled from timber, which is laid on the foundation. Floor joists are attached. In this case, the floor can even be assembled immediately - it will be more convenient. The next steps are raising the walls, which is made from boards joined “in a tenon”.

This way the walls are raised to the required height. After this, you can strengthen them from the inside, lay insulation, vapor barrier film and cover them with clapboard. The roof rises similarly to the previous version. But if how to build a bathhouse from boards with your own hands is more or less clear, then an even more complex option remains to be dealt with.

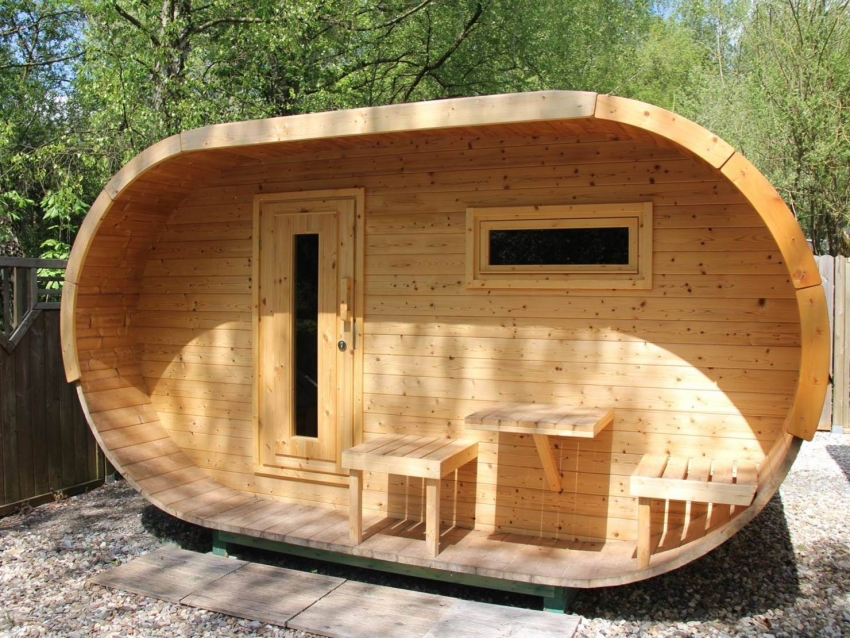

Barrel sauna - what is it and how to build it

A barrel mini sauna is a rather interesting structure that will decorate the landscape of any area. If we make comparisons, then the most suitable here would be a small tank with cut out windows and a door. Let's try to understand how it is assembled.

Among the advantages, in addition to appearance, one can point out the absence of a foundation for such a building, which means the structure will be mobile. Of course, provided that it is firmly assembled. For the walls you will need an edged board (it is better to use spruce or larch) which is connected using the tongue-and-groove method, like lining. But the board should be much thicker. The base is made of 5-6 boards at least 5 cm thick, standing on an edge with a semicircular notch.

The barrel sauna is difficult to build, but it looks its best

Further along, on the supports, boards prepared for the walls are laid. After assembling the lower part of the walls, round partitions are assembled in the same way with recesses for the door. Well, after that you can assemble the walls completely in a circle. As for the interior decoration, there is complete freedom of imagination. We offer several examples that will help explain how to build a barrel sauna with your own hands.

This is roughly what happens. But no matter what method the bathhouse is built, it is very important what it will have inside.

Components and equipment - what needs to be installed inside

Of course, everyone knows that the stove is the most important thing in a sauna. But in addition to the required elements, you can think of what else you can supplement it with. And yet, first of all, about the main thing.

Mini stove for a bath – buy or make?

This question cannot be answered unequivocally. If a home craftsman has experience in making such equipment, then, of course, a do-it-yourself mini stove for a wood-burning sauna will be preferable. If not, then you will have to purchase a similar heat generator. In this case, a good and relatively inexpensive solution would be to purchase a “Varvara mini” sauna stove.

Bath stove "Varvara mini" is a very good choice

Do you need a pool in a mini sauna and how to arrange it?

It makes sense to purchase a swimming pool for mini baths only if the size of the building allows it. Although sometimes it is installed directly next to the building. Of course, this is a pretty good way to relax after a steam room, but if the area is small, it may be overkill.

Sauna inside a bathhouse – what’s good about this option?

A mini sauna in the country will be very useful for those in whose family not everyone likes a hot enough steam room. Then, by making a firebox on the back side of the door, you can fence off a small room inside. The temperature in it will be significantly higher than in the washing room. This way, those who like intense heat will be able to relax with a good steam. Others will be in the next room, where the heat is not so strong.

Bathhouse projects with a relaxation room and a terrace. In a separate publication you will learn about the most successful layouts of bathhouses with an extension in the form of a veranda or terrace.

Advantages of a self-made small bathhouse in the country

Before building a mini sauna for a summer house with your own hands, the project is the first thing you should think about. Without it, nothing meaningful will happen.

You can make such a bathhouse if there are no neighbors nearby and there is nothing to be embarrassed about

Of course, a small bathhouse in the country is a necessary thing, and therefore such a construction is worth starting, despite the apparent complexity. Well, if you have a complete lack of desire and desire for construction, you can purchase a ready-made steam room, which will be delivered to you directly to your yard. The only thing you need to do is prepare a flat area for it.

Finishing the bathhouse inside. Photos and examples. In a separate publication you will find interesting ideas for finishing steam rooms and relaxation rooms, and also learn the main stages of installation.

Where can you buy a mini sauna for your dacha inexpensively?

Nowadays, you can order a finished building quite easily - the Internet is replete with such advertisements. The question is that the cost of such a building is quite high. Now let’s try to figure it out at what price you can buy a mini sauna for your dacha.

Thus, you can understand that it is unlikely to be possible to purchase a turnkey bathhouse for your dacha inexpensively. That is why it is worth thinking about DIY construction. In this case, you can meet less than half of the market price, or even a third. Of course, you can buy a sauna for your dacha inexpensively, but in this case you will only receive a box without interior decoration and a stove. And this will be a barn, not a steam room.

Examples of small bathhouses made by hand at the dacha - photo review of interesting solutions

Perhaps someone else doubts whether it is worth starting construction. We invite you to look at a few photos of mini baths for summer cottages with your own hands.

This is roughly how you get homemade, quite beautiful steam rooms. Agree that small bathhouses for summer cottages look simply lovely in the photo.

Summarizing

Summarizing the material presented, we can draw the following conclusions:

- If you decide to start building a bathhouse with your own hands, the first thing you need to do is draw up a project;

- Next, think through everything thoroughly and purchase the necessary material;

- You need to approach work carefully and carefully, but at the same time creatively;

- There is no need to rush in this matter, but you should not leave an unfinished bathhouse for the winter either.

And if you follow these simple rules, then a mini sauna at the dacha will not only please the eye, but also soothe the soul, and give health and joy to you and your loved ones.

Do-it-yourself mini sauna for a summer residence: materials, components, models

Mini sauna for a summer residence: materials from which it can be made, components and equipment, advantages, review of purchased models, useful tips and recommendations from experts.

Homemade construction portal

Mini baths in the country: how to make it yourself. Device description location of mini baths in garden and summer cottages

Surely every happy owner of the notorious 6 acres outside the city tries to make the most of his Not large plot land. Plant fruit trees, organize a small vegetable garden, and build a two-story house, albeit with only two rooms. And where there is a house, there is a desire to build a bathhouse, so that if you relax, then to the fullest.

There is absolutely no reason to be upset and upset if the area of your site is not large enough to build a bathhouse of standard sizes. You can consider a compact project mini baths in the country. A small sauna built with your own hands meets the needs of steam lovers just as much as a standard one. And in terms of saving free space and material costs, its construction will certainly be of interest to the thrifty owner.

The size of your future bathhouse must be calculated based on the number of people who will use it. For a small family consisting of 2 or 4 people, a budget option for a small building is quite suitable. The height of the bathhouse in such a project will be 2 m, the length will be 6 m, and the width will be only 2 m 20 cm.

The interior space of the mini bath should be divided into 4 separate rooms, each of which has its own purpose. The dressing room is included in the design of any bathhouse, and for a small bath house its area can be no more than 1.5x2 m. Of course, you can’t do without a rest room, the parameters of which in this case will be 2x2 meters. For two or three people it will be quite possible to stay in such a room. The remaining room of the mini bath is allocated for a tiny shower room, with an area of 1x1 m, and, in fact, a steam room, with the same dimensions as the dressing room - 1.5x2 meters. For a shower corner and steam room, it will be necessary to make additional calculations of the area, taking into account the arrangement of the shower tray, and the placement of shelves in the steam room.

The stages of building a mini bathhouse at the dacha are carried out in the usual sequence. Despite the fact that our bathhouse will be very small, the construction rules for it are the same as for all other buildings.

You should start by building a foundation. At this stage, an extremely important point is the type of soil on which the bathhouse will be located.

If the ground is sufficiently dry and hard, then you can use a simplified version of the foundation. First, flat stones are laid around the perimeter of the future structure, then the same stones are laid in the interior of the foundation. The free spaces between the stones are filled with clay and compacted thoroughly. A layer of wooden beams is placed on top, treated over the entire surface with hot bitumen.

You don’t have to use clay, but lay the foundation of a mini bathhouse out of stones alone – “solid”. In this case, it will be necessary to cover the stone foundation with a layer of waterproofing.

Most often, a columnar foundation is made for a bathhouse, using brick, stone, ready-made asbestos concrete or concrete pipes filled with the same concrete. The structure can be installed on metal, wood or concrete piles. But then you will need to take care of additional thermal insulation of the bathhouse floor.

The most reliable and common is the strip foundation. To make it, a trench is dug, which is filled layer by layer with wet compacted sand and crushed stone. Then they knit the reinforcement and fill it with concrete. As usual, roofing felt is used as waterproofing.

If the soil on your site consists of sand and is filled with groundwater, then concrete blocks can be used to create a foundation for a mini bathhouse. For a small, lightweight structure, 10 blocks with standard dimensions of 20x20x40 cm are sufficient.

The first step is to install the frame of the future bath house and erect the walls. After this, the walls of the dressing room, rest room and shower are insulated with a mixture of expanded clay and sawdust. The insulating mixture is covered with polystyrene sheets and the walls of the mini bath are lined with clapboard. Can be added to sawdust and expanded clay broken glass, which will protect your bathhouse from the penetration of rodents into the interstitial space.

The walls of the steam room require special treatment. Therefore, about 5 cm of free space is left behind the lining, a heat and vapor barrier film is placed there, and then the air gap is filled with mineral wool. It is rational to make the walls inside the shower room from galvanized steel or polystyrene, which can withstand frequent contact with water much better than wood.

If there is no pressure water supply in your area, the water supply to the mini bath can easily be made by gravity. To do this, you need to build a structure from two galvanized tanks, each with a volume of 50 liters, hoses and a mixer.

Tank with hot water installed at a level half a meter lower than the installation level of the cold water tank. One end of the connecting hose is fixed at the bottom of the “cold” tank, and the second is connected to the top of the “hot” tank. The temperature difference will ensure independent circulation of water through the pipes. To supply water to the shower, both tanks are connected by a separate pipe, at the end of which a mixer is installed.

To equip a water drain, a few drainage pipes and a drainage hole will be enough. The pipes are positioned at the desired angle, and the water flows by gravity into the pit.

The water in the mini bath is heated using a stove installed in the steam room. You can also use a heating element for these purposes, which can be easily purchased in a store.

If you heat water with a stove, you need to install a U-shaped pipe in the hottest part of the stove, wrapping it around the base of the chimney. The water supply end of the pipe should be located on the body, and the outlet end should be located 5 cm higher from it.

The heating element is placed under a cold water tank and connected to the system with hoses and stainless steel pipes.

It is not difficult to provide ventilation for a small bathhouse. To do this, you do not need to buy any additional devices. It is enough to make a small hole in the wall opposite the entrance door, which can be easily opened or closed using a damper.

To illuminate a mini bath, several halogen lamps with a heat-resistant housing are sufficient. Using a small transformer, you can easily reduce the voltage from 220 to 12V.

As you can see, building a mini bathhouse with your own hands is not that difficult.

Let's look at an example of a compact mini bath for one person.

To assemble such a bathhouse, you will need lightweight insulated panels, which are a frame made of wooden beams covered with thin boards. The size of one frame is 185x60 cm, and in its manufacture they use timber with a cross-section of 3x6 cm and boards 1-1.5 cm thick. To insulate and provide heat and vapor barrier, the panels are filled with foam plastic or mineral wool, covering it on the inside with polyethylene film or aluminum foil . The outer side is covered with glassine or roofing felt. Then the panels are covered with clapboard.

In one of the panels a door is made, measuring 160x60 cm, in which a small window with double glass is provided. Door locks at the top and bottom of the doorway ensure the tightness of the bathhouse. At the bottom of the panel, near which the heating device will be located, make a small ventilation hole with a plug.

How to build a mini sauna for one person on the street? Very simple. It is necessary to assemble a structure of the required size and provide it with hydro- and thermal insulation.

For a single steam room with an internal area of 180x130 cm, 10 panels for the walls and two for the roof are enough. The seams of the structure are filled with batting and covered on both sides with wooden planks. The ceiling of the mini bath will be protected from precipitation by a triple layer of roofing material.

If you intend to use the bathhouse only in the warm season, then the floor of the structure does not need to be insulated. For year-round use, a strip foundation with insulating jumpers is poured.

To heat a single steam room to 80-90 degrees C, use a closed-type electric stove with a power of 3 kW. Place a metal bucket or box of stones on the stove and turn it on for several hours. After this, you can begin bathing procedures.

In an apartment, in your bathroom, a small bathhouse with your own hands can also be equipped quite quickly and easily. There are two ways to arrange a mini bath with electric heating in the bathroom.

The first option involves installing a removable shelf at a height of 1 meter from the floor on two beams. The beams must be securely fastened to the walls with strong pins. The height of the shelf above the bath is 40-60 cm.

To climb onto the shelves, a small ladder with rubber bearings is made. To avoid injury, the ladder must be tied to the shelf with twine. The width of the shelf is 60 cm. The steam room is heated with an electric stove, which is placed on a reinforced stand above the sink. The heater in this version is a metal basin or bucket, which is filled with stones and placed directly on the stove.

In the second option, they make a sitting steam room on the bathtub, covering it with removable wooden panels. In this case, the shelf serves as a seat, and you can not only rest your feet on the durable panels, but also stand on them. Hanging at a short distance from the shelf wooden block and throw their legs over it.

To achieve maximum resemblance to a bathhouse, the walls and ceiling above the bathtub are covered with wooden slats or removable panels are mounted from boards. If necessary, such shields are easy to install and remove.

Heating of a mini bath is also carried out using an electric stove with a container with hot stones placed on it.

Don't forget about safety precautions and enjoy the mini sauna you built with your own hands!

Do-it-yourself compact mini baths

Today, a private house or cottage is unthinkable without a bathhouse, which has become an indispensable component of country life. But what to do if there is not enough money to build a full-fledged bathhouse with all the attributes? Or is the plot so small that it is impossible to place a large building on it? For those who experience such problems, there is one solution - a mini sauna for the dacha.

What is better to choose – a ready-made or a homemade mini-bath?

Anyone who has a certain amount of money, but does not want to waste time and energy, can safely buy a miniature bathhouse that is completely ready for use. Otherwise, you will have to start building a mini bathhouse with your own hands. On the Russian market, ready-made mini bath projects are presented in a wide variety. Unfortunately, not all of them are of acceptable quality, so you need to be especially careful when choosing.

Products of this kind must meet the following requirements:

Small dimensions and weight

Ease of installation - the ability to do without constructing a capital foundation or laying additional communications

Ready for use quickly

Functionality combined with ease of use

Beautiful appearance (optional).

The most successful example is the mini bathhouse project called Emelya. It meets the above requirements as much as possible. Due to its low weight (only 500 kg), there are no problems with transportation and no capital foundation is required. Despite its compact size, Emelya’s mini bathhouse is equipped with everything necessary and includes all the traditional premises of a Russian bathhouse: dressing room, shower room and steam room. To start the sauna, a simple extension cord is enough, through which it is connected to the home electrical network. At the same time, the electric oven is made in a safe version, so you can use it without fear even while washing (see photo).

Inflatable bath models

Among the ready-made projects there are options for the lazy (see photo below). These are portable inflatable models. They are a soft, elastic body made of ultra-strong and lightweight polymers. To prepare such a bath, a few minutes and 2-3 simple operations are enough:

Connects to the pump and fills with air

Then all that remains is to fill the steam generator with water.

After use, the case is freed from air, collapses and can be stored in a regular sports bag. The complete set weighs only a few kilograms, so you can take the inflatable bathhouse with you anywhere. An inflatable mini sauna is especially good in a country house where there is no running water, sewerage and other amenities, without which it is impossible to build a regular sauna.

Do-it-yourself mini sauna is small frame construction, divided into functional zones by light partitions, the internal space of which is filled with insulation and waterproofing. To save volume, as a rule, modern materials are used that combine both of these properties. For example, roll insulation, covered on both sides (or one) with a layer of foil or membrane vapor barrier.

We build it ourselves - where to start?

On clay soils, a concrete pit will be required to collect and subsequently drain water into the drainage ditch. Since a small diameter pipe is used for this, the drain hole in the floor must be protected with a fine-mesh filter.

Then a frame is erected from vertically installed timber and a horizontal strapping system. The frame is covered with clapboard on both sides, and the internal space is filled with reliable insulation, resistant to water, or protected by hydro- and vapor barrier.

When using the bath small sizes The issue of saving free space is acute. This imposes certain requirements on the design of the shelves and oven. On the one hand, the stove must be powerful enough to heat the steam room well and quickly. On the other hand, maximum compactness is required.

You can purchase ready-made mini sauna stoves or make them yourself. Naturally, the first option is simpler, but also expensive, since the price of high-quality samples today ranges from 30 to 60 thousand rubles. depending on the country of manufacture and configuration. In general, factory models are a metal body-firebox, on top of which there is a platform for the heater. The water tank can be:

hinged, when it is mounted on the side surface of the body and heating occurs due to heat transfer directly from the firebox

separate, in this case it is installed at a height, and the chimney acts as a coolant, through which combustion products are removed from the firebox.

You can assemble a mini sauna stove yourself. Moreover, this will not require special skills and abilities, but the savings will be significant. For those who are interested, we will briefly describe the technological process of creating the simple option stoves for a small bath.

A simple version of a homemade stove for a mini steam room

The main element is a regular cast iron sink. First, its surface must be completely cleaned of enamel, which, when burned, will give off an unpleasant odor.

Then the firebox body is prepared - it is made up of bricks laid in 9 rows, as shown in the figure. In order to comply with measures fire safety, at the place where the furnace is planned to be installed, first lay a flat asbestos cement slate, on top of which a sheet of metal about 1 mm thick is attached.

Next, three lower rows of continuous masonry are made. The bricks are laid on a clay-sand mortar with a joint thickness of 3 to 5 mm. After this, three walls are built into one brick. One wall is missing, since instead there will be an open firebox, that is, a hole for loading firewood, without a door. To make it easier to form the firebox, you can use a special frame welded from corners. Bricks are laid into its grooves using the “poke” method.

The dimensions of the oven are selected in such a way as to ensure that the sink can be tightly installed on lateral ribs rigidity, as shown in the figure above. The drain hole should be located near the wall opposite the open firebox. This is a mandatory condition, since this hole is used to remove flue gases. For this purpose, a pipe of suitable diameter and length of at least 2.5 m is inserted into it.

Water in a bathhouse equipped with such a stove can be heated in several buckets installed next to the heater, but it is better to make a 40-50 liter tank, which is placed directly on the stones. In summer, you can even get by with a container on the roof where the water is heated by the sun’s rays. It is advisable to make the shelves in a small bathhouse removable or folding, with fastening to the wall through a hinge device. This allows for more efficient use of the limited footage of the steam room.

Installation of mini baths in garden and summer cottages

People's need for bath procedures ah is so high that the possibilities for improving the bathhouse are sought with great ingenuity.

It is known that baths are equipped on car trailers, ships, submarines and even in spacecraft. Temporary baths are set up at the camps of tourists, prospectors, and field camps.

It is quite natural that in summer cottages and gardens, and even in apartments, they also set up simple bathhouses that allow you to steam and wash. They are called mini-baths.

Let's consider two options for a mini-bath installed in the bathroom using electric heating.

The first version of a mini-bath

In the first option for installing a bathhouse, at a height of 1-1.3 m from the floor (0.4-0.6 m above the bathtub), a removable shelf is mounted on two beams nailed to the walls with strong pins.

The width of the shelf is 55-60 cm. To climb onto it, use ladder with rubber bearings. The ladder is tied to the shelf with a rope.

An electric stove with stones is installed on a stand above the sink.

The stand must have its own support on the floor to protect the sink from destruction.

The second version of the bathhouse

In the second option, the shelves are made to sit, and the bath is covered with removable wooden panels that you can stand on.

To place your legs in a raised position, hang a planed block or stick at a distance of an outstretched leg from the shelf. To climb onto the bathtub, you can use a low bench or stool.

To assemble a bathhouse on outdoors Instead of shields, it is necessary to make insulated lightweight panels.

To do this, frames measuring 185x65 cm are made from beams with a cross-section of 3x6 cm and sheathed with boards 1-1.2 cm thick.

Before covering the panels, they are filled with foam plastic, mineral wool or straw, covering them on the inside with aluminum foil or polyethylene film (moisture and vapor barrier), and on the outside with roofing felt or glassine.

The number of shields depends on the required size of the steam room.

One panel contains a door with a built-in window. At the same time, the height of the threshold is 20 cm, the dimensions of the door are 160×60 cm, the dimensions of the window are 36×25 cm.

The window must have double glazing.

To ensure the tightness of the closure, the locks on the door are made in two places: below and above. At the bottom of the panel where the electric stove is installed, a ventilation hole is made that is closed with a valve or plug.

From 12 panels (10 for walls and 2 for ceilings) a steam room with internal dimensions of 130x180 cm is assembled, in which you can equip a shelf-bed.

For a steam room with internal dimensions of 130x110 cm with a bench shelf, it is enough to have 10 panels or 8 panels measuring 185x56 cm (for walls) and 1 panel measuring 130x150 cm for the ceiling.

The seams of the panel are sealed with batting and covered on both sides with wooden slats.

The outside of the ceiling is covered with 2-3 layers of roofing material.

Bath floor design

The design of the floor depends on the location of the mini-bath. If it is placed in an open area and is intended for use only in summer, then the floor can be made of boards without additional insulation.

For use in winter, the foundation must be strip or have insulated lintels that protect against blowing from below. If a mini-bath is installed indoors, then the main requirement for the floor is to ensure proper insulation from leakage, collection and direction of wastewater into the sewer.

Heating devices in the bath

As heating device They use a closed-type electric stove with a power of 2-3 kW, on which they place a metal box, bucket or jar with stones.

To warm up the steam room to 80-90° C, the tile is turned on for several hours, and before the bath procedures it is turned off for safety. Before heating the room, remove all metal, plastic and flammable objects, curtains, curtains.

Metal objects heat up quickly and can cause burns if you come into contact with them.

Plastic objects deform at high temperatures.

Curtains and drapes make it difficult to heat the room and are a fire hazard.

How to speed up heating of a bath

To speed up heating, you can use an additionally installed electric heater.

By creating artificial air circulation, it ensures more uniform heating of all parts of the room. In this case, the power of the electric stove with stones can be reduced to 1.2 kW.

It’s even better to heat the stones on a gas stove in the kitchen, placing them in a mesh container made of thick steel wire, then put them in a metal bucket with a lid and bring them into the steam room.

If there is a source of hot water, for example, a gas water heater located in an adjacent room (kitchen), you can speed up the heating of the mini-bath by filling the bath with hot water. In this case, the bathtub should be covered with a wooden board or grate covered with film (oilcloth) to reduce water evaporation and prevent increased air humidity.

Mini-sauna - economy option

In order to make a sauna in the shortest possible time, we offer the option of a small mini-sauna, which can be built in one month and immediately begin to be used. This is an important factor, since a log bathhouse must be kept for about a year before use for its walls to shrink.

The dimensions of the mini-bath may well suit a family of two or three people (Fig. 12). The steam room, combined with a washing room, is equipped with a two-level shelf. There is a shower, the water tank of which is located on the roof of the bathhouse.

The structure of the mini-bath frame is similar to that described above, so during its construction you can use the same structural components and elements. The main feature of the proposed mini-bath is a small stove-heater, which can be made without much expense or difficulty.

It is based on an old kitchen cast-iron sink, installed with ribs along the perimeter on brickwork, that is, the sink is lined with brickwork on three sides, and on the side opposite the drain hole, an open (without door) heater firebox is installed. The bottom double row of bricks is laid out on a metal sheet 1 mm thick, which in turn is laid on a flat sheet of asbestos slate.

This protects the floor from fire. To improve the heat transfer of the stove stones, as well as to eliminate unpleasant odors in a bathhouse to prevent the enamel from burning out, the sink must be cleaned of it before placing it in the oven. For the flue gas trunk, a sink drain hole is used, into which you need to install a metal section of a chimney pipe with a diameter of 60-80 mm and a length of 2.5 m, on which to attach the upper part of the chimney, individual sections of which can be made independently from sheet steel 0.8- 1 mm.

The small dimensions of the heater (Fig. 13) (750 x 500 x 720 mm) allow you to arrange half a room in the steam room. The brickwork of the heater stove should be done using clay-sand mortar with a seam thickness of 3-5 mm. To form a firebox, a frame of 65 * 65 mm is welded from a corner, into the grooves of which bricks are placed on a stick along the perimeter. Thus, the cast-iron sink, resting on these bricks, forms the combustion chamber of the heater stove. Stones placed on top of the sink heat up very quickly both from the walls of the sink and from the metal chimney, which allows you to quickly heat up a small volume of the steam room (5.5 m3).

Water for bath procedures can be heated either in several buckets installed on the side of the heater, or in a tank with a capacity of 40-50 liters. IN summer period A small tank (80-100 l) for showering will be placed on the roof of the bathhouse. The drainage of water must be done in the area of the second shelf of the shelf, arranging a drainage hole and draining the water before installing the floor.

When starting the construction of both a capital family bathhouse and a small bathhouse, the owner of a rural farmstead must also perform some work on its external and internal arrangement, which is directly related to the operation of the bathhouse. Such work includes a drainage system for removing used water, installing a shelf in the steam room and laying out the chimney of the heater.

A drainage hole is made before laying the logs and bathhouse floor boards. This is a serious matter, since poor water drainage can damage the bathhouse.

If the soil on the site is sandy or sandy-gravel, that is, it easily absorbs water, then under the bathhouse it is enough to dig a regular drainage hole, the dimensions of which usually depend on the size of the structure and water consumption. For example, if a family of 3-4 people will use the bathhouse, it is enough to make a hole 70 x 70 cm and 60 cm deep. The drainage hole is filled with broken bricks, large crushed stone or gravel. Around the pit, the soil is compacted with a wooden tamper and covered with roofing felt with a slight slope on all sides towards the pit.

In the case of clay soil, draining used water from the bathhouse will require much more work and expense. Instead of a drainage pit, a concrete pit measuring 50 x 50 is required; 60 x 60 cm, depth 50-60 cm and wall thickness 10-12 cm. To drain water from the pit, you can use a drain pipe with a diameter of 50-70 cm. It must be placed at a distance of about 10 cm from the bottom of the pit. It is necessary to install a float water seal in it so that unpleasant odors do not penetrate into the bathhouse. A fine-mesh filter must be installed in the drain hole of the bathhouse floor, located above the pit, to prevent clogging drain pipe garbage.

The shelves are installed after laying the floor and installing the heater on it. In a small steam room (especially in a mini-bath), it is advisable to make the shelves either folding (hinged) or completely removable, which will ensure more rational use of the limited footage of the steam room. In addition, removable shelves can be removed for cleaning and drying.

Only completely smooth boards and planks are suitable for arranging a shelf. The boards must not be impregnated or coated with any varnishes, solutions, or paints. All edges, especially the outer ones, should be rounded. It is advisable to arrange the shelves from wood species with soft and non-resinous wood (linden, aspen, poplar), since the boards from them heat up less.

In a small steam room you can build two-tier shelves (Fig. 14), and for large family baths - three-tier ones. Shelves are usually arranged along a wall that does not have a window, and the size of the upper tier should be taken based on the average height of a person, that is, 175-185 cm long and 65-70 cm wide.

The upper floor should be placed approximately at the same level with the stove stones so that the space around it warms up faster and better. The height between the top shelf and the ceiling of the bathhouse should be sufficient to make it convenient to steam with a broom, that is, 100-110 cm.

The second shelf should be located from the floor at approximately 70-80 cm, its width should be 45-50 cm. Portable wide and stable benches are placed near the two-tier shelf to make it easy to get down and climb onto the desired tier. For the same purposes, sometimes a small, reliable ladder is installed.

On shelves, to fasten boards together, it is necessary to use copper-plated or galvanized nails and screws, the heads of which must be sunk into the wood. The thickness of the boards depends on the distance between the supports on which they rest. The greater this distance, the thicker the board should be. For example, a board with a thickness of 20 mm is used with a distance between supports of 500 mm, 25 mm - respectively with 900 mm, and boards with a thickness of 40 mm can be used with a distance of 1200-1300 mm.

Mini baths in the country: how to make it yourself

The water in the mini bath is heated using a stove installed in the steam room. You can also use a heating element for these purposes, which can be easily purchased in a store.

Who hasn’t dreamed of building a real bathhouse on their summer cottage? But sometimes it is so small that a full-fledged bath structure simply cannot be squeezed in there. In this case, a mini-sauna can be an excellent way out of the situation. In terms of comfort and functionality, it practically does not differ from a standard-sized bathhouse, and the time, effort and money to build such a structure will take much less. In addition, it is quite possible to make a small bathhouse with your own hands. This will be discussed further.

Features of designing the interior space of a bathhouse

When creating any project, the first step is to select the appropriate material for the construction of the structure. And the bathhouse is no exception in this matter. Thus, when constructing a bath structure, builders mainly use materials such as foam blocks, bricks, timber or solid logs. Professionals recommend giving preference to natural materials – wood. But this is no longer a matter of taste, but of financial capabilities.

When designing a small bathhouse, it is necessary to adhere to the same technologies as when planning a bathhouse of standard sizes. But in our case, it is still important to take into account some points:

- To build a small bathhouse, a powerful, complex foundation is absolutely not required, since we are talking about small loads. Therefore, in order to facilitate the excavation process and reduce the cost of funds, it is quite possible to get by with a strip/support-pile one.

- The location of functional areas should be approached very seriously, since in a small structure, all the flaws and imperfect layout will be immediately noticeable and will certainly cause inconvenience.

- It is best to place the stove in the dressing room so that it does not interfere with going from the washing room to the steam room and vice versa. The firebox must be protected as much as possible from spontaneous combustion.

- The principle of building rooms in a mini-bath should be absolutely the same as that of a standard one. So, the shelves must be installed along a blank wall, the door threshold should be raised as high as possible, and the frame should be made low. All this is done with the aim of trapping steam inside even when the door is opened.

- Under no circumstances should there be locks in bath rooms, and all doors should only open outwards.

Attention! To make it convenient to wash and comfortably steam in a bathhouse, the area of the structure must be calculated in such a way that its useful part is at least 10 square meters. m.

Basic drawing of a mini bath: a compact and functional solution for a summer residence

So let's consider simplest project bath design. Any bathhouse should have four main rooms: a dressing room, a washing room, a steam room and a relaxation room. It is necessary to clearly understand what minimum dimensions each of them can have. So, for the waiting room and steam room you can choose optimal sizes– 1.5x2 m; the washing area can be 1x1 m; and the rest room is 2 times larger than the washing room.

Construction of the foundation

After determining all the main parameters bath rooms You can proceed directly to construction work. Choosing suitable type foundation, pay special attention to the type of soil of the area on which the bathhouse will be built. If the soil is hard enough and the groundwater is deep, then a lightweight foundation will be sufficient. We lay flat stones around the markings of the future building, cover them with a small layer of clay and lightly press them. We lay wooden beams on top. We complete the process by covering the beams with waterproofing bitumen.

If there is soft or wet soil on the site, use a strip foundation. Prepare a trench, fill it with a layer of sand, then crushed stone and compact it tightly. Then place the reinforcing mesh on top. All that remains is to prepare a cement solution with which the pit will need to be filled. Don’t forget about waterproofing: roofing felt sheets can be used for this purpose.

Frame construction

There are many options for constructing bath walls. We will use the simplest and fastest - frame. For its construction we will need the following materials:

- wooden blocks (5x5 cm);

- boards (minimum thickness – 2.5 cm);

- foil/film for waterproofing;

- thermal insulation.

Frame mini bath: the simplest and fastest construction option

According to a previously prepared project, a frame of beams is assembled. The inside is lined with boards. You can use ordinary screws or anchors as fasteners. Don't forget about heat and waterproofing. The first thing we install is a material that does not allow heat from the bathhouse to pass out. For this purpose, you can use expanded clay, sawdust or mineral wool (rarely used). Bitumen mastic is suitable for creating a waterproofing layer. The final stage of wall construction is the internal board covering (not mandatory, but a desirable element).

Advice. For finishing the washing area, it is best to use materials that can withstand frequent contact with water: galvanized steel, polystyrene, etc.

All that's left to do is build the roof. First, we prepare the rafter system and mount it on the frame. Then we begin laying the roof: metal tiles, slate, etc. will do. Don't forget about the chimney - you need to leave a free opening on the roof for it.

To complete the appearance of the bathhouse, lining or a block house is used as a protective and at the same time decorative element. Lining is the most common option for finishing the external frame of a bathhouse. This material is cheap, practical and durable. In addition, it is a fairly successful imitation of a wooden beam. The block house is similar in appearance to the lining, but differs in a more presentable appearance and quality of wood.

A mini bathhouse externally lined with wood will delight you with its aesthetically pleasing

Conducting communications